What is a black oxide coating? Why is surface treatment necessary?

Black oxide coating is a widely used protective process for metal workpieces. It effectively improves the corrosion resistance of ferrous metals and enhances their overall performance. Ferrous metals are widely used due to their excellent strength and hardness, but they also have significant weaknesses: they are prone to oxidation when exposed to oxygen and moisture in the air, leading to rust.

Metal corrosion not only reduces the structural strength of materials but can also cause safety hazards. Therefore, preventing the oxidation of ferrous materials is a crucial aspect of engineering. Among various protective methods, applying a black oxide film is a highly efficient approach, significantly improving the corrosion resistance of metal parts and extending their service life.

Not only for ferrous metals, but also for other metals such as copper and zinc, blackening is a highly effective surface protection method. This process is often called "blackening," "smoking," or "dyeing," and belongs to chemical conversion coating technology—its essence is to change the surface structure of the metal through a chemical reaction, rather than simply attaching an outer coating.

This article will explain the basic principles of black oxide treatment and illustrate its practical value in steel processing and manufacturing. We will also analyze the main advantages and limitations of this technology and introduce its most suitable application areas.

What is Black Oxide?

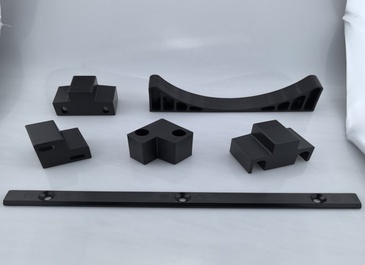

A black oxide coating is a black or dark gray conversion coating formed on a metal surface. It is not a simply applied "plating" or "paint," but rather a chemical reaction that transforms the metal surface into a protective compound. It is used to improve the metal's corrosion resistance, reduce light reflection, and improve its appearance.

Core Purpose of Black Oxide Treatment

The primary purpose of black oxide treatment is not to significantly improve corrosion resistance (its rust prevention ability is far lower than electroplating zinc or chrome plating), but rather to achieve the following functions:

Reducing Light Reflection and Anti-Glare: Provides a uniform matte black appearance, eliminating reflections, commonly used for internal parts of optical instruments, firearms, and tools.

Enhancing Aesthetics: Gives products a deep, professional black appearance.

Slightly Improved Corrosion Resistance: Provides basic rust prevention, especially after applying rust-preventive oil, its rust prevention ability is significantly enhanced.

Relief of Residual Stress: The heating during the process helps eliminate minor stresses from machining.

Minimal dimensional impact: The resulting oxide film is extremely thin (typically only 0.5-2 micrometers), barely altering the dimensions and tolerances of the part, which is crucial for precision components.

Improved lubricity: The porous structure of the oxide film effectively adsorbs and retains oils, reducing friction and improving wear resistance.

What is the working principle of black anodizing?

The core principle of black anodizing is a high-temperature chemical reaction between the metal and a specific chemical solution. The process typically involves three steps:

Pretreatment: Thoroughly clean (degrease, pickle) the metal surface to remove oil and rust.

Main reaction: Immerse the workpiece in a high-temperature (approximately 135-150°C) alkaline solution (containing sodium hydroxide, sodium nitrite, etc.). Iron reacts with the solution to form a stable Fe₃O₄ film.

Post-treatment: To significantly improve corrosion resistance, blackened workpieces must be immediately immersed in oil, waxed, or sealed to fill the micropores in the oxide film.

Black Oxidation Process Flow:

Cleaning: Thoroughly clean the metal parts to remove dirt, grease, and other contaminants, forming a uniform, defect-free coating on the surface.

Rinsing: Rinse the parts to remove any cleaning agent residue that may interfere with the chemical reaction.

Immersion: Immerse the cleaned metal parts in a blackening solution containing oxidizing salts as well as sodium hydroxide, nitrates, and nitrites.

Temperature Control: Depending on the process, maintain a stable temperature (very hot, moderately hot, or room temperature) during immersion. Immersion time typically ranges from a few minutes to one hour, depending on the desired degree of blackening.

Reaction: The oxidizing agent in the solution reacts with iron atoms on the metal surface to produce black oxides.

Rinsing: Remove the oxidized metal parts from the solution and rinse thoroughly to terminate the chemical reaction.

Sealing: Apply an oil- or wax-based sealant to the finished parts, allowing it to penetrate the crevices of the porous oxide layer, significantly improving the corrosion resistance of the parts. This step should be repeated periodically throughout the part's lifespan.

Types of Black Oxide Coatings by Material

Black oxide treatments are mainly divided into two categories: black oxides on steel and black oxides on non-ferrous metals. Their principles, formulations, and final products are quite different. The table below shows the different black oxide coatings that can be formed on different metals, including a comparison of process variations and results.

Summary Comparison Table

| Material Category | Main Process Principle | Typical Black Product | Primary Functions |

|---|---|---|---|

| Steel/Iron | Alkaline Chemical Oxidation (Mid/High Temp) | Magnetite (Fe₃O₄) | Aesthetics, Glare Reduction, Basic Rust Prevention (Requires Post-Treatment) |

| Stainless Steel | Acidic Chemical Oxidation (Chromate) | Chromium/Iron Oxide Composite Film | Aesthetics, Glare Reduction, Mild Corrosion Resistance |

| Copper & Alloys | Oxidation or Sulfidation | Copper Oxide/Copper Sulfide | Decoration, Antique Appearance |

| Zinc & Alloys | Black Passivation | Chromate/Metal Sulfide Composite Film | Decoration, Corrosion Resistance |

| Aluminum & Alloys | Anodizing + Coloring (Dyeing/Electrolytic) | Porous Alumina + Colorant | Decoration, Wear Resistance, Weather Resistance, Corrosion Protection |

| Magnesium Alloys | Chemical Oxidation (Chromate) | Chromate Film | Corrosion Protection, Coating Base |

| Titanium Alloys | Anodizing | Interference-Effect Titanium Oxide Film | Aesthetics, Functionality, Biocompatibility |

Advantages and Disadvantages of Black Oxide Coatings

Next, we will analyze the advantages and disadvantages of black oxide coatings in detail. It is important to emphasize that these advantages and disadvantages are highly dependent on the substrate material and post-treatment process.

Advantages of Black Oxide Coatings

Aesthetics and Feel: Provides a uniform, deep matte or semi-matte black surface with an elegant color, offering an industrial feel or high-end decorative effect. Feel: After oil or wax sealing, the surface is smooth and delicate.

Excellent Dimensional Stability: Black oxide is a conversion coating, with a film thickness typically only 1-3 micrometers. It does not change the critical dimensions and tolerances of the part, making it ideal for precision parts, threaded fasteners, gears, etc., where dimensional accuracy is extremely important.

No risk of hydrogen embrittlement: The process does not involve electrolysis or pickling (or pickling followed by thorough neutralization), preventing hydrogen atoms from penetrating into the steel substrate and causing hydrogen embrittlement, unlike electroplating. This is crucial for high-strength steel and spring steel.

Good frictional properties: The oxide film itself is porous, and after absorbing grease, it forms an effective oil film, providing self-lubrication and friction reduction during initial operation, reducing wear and seizing. It is commonly used in engine parts, firearm components, etc.

Strong adhesion: Because the oxide film is a product of the base metal's own transformation, it has excellent adhesion to the substrate, unlike paint or electroplating layers which may peel or flake.

Enhanced effect: The porous oxide film structure is an excellent substrate for oils, waxes, or certain polymer sealants, greatly enhancing the adhesion and protective effect of these post-treatment layers.

Disadvantages and limitations of black oxide coatings

Very limited corrosion resistance :This is the biggest misconception and drawback. A simple black oxide film (Fe₃O₄) has almost no rust-preventive ability. It relies on post-treatment sealing (oil immersion, wax immersion, or polymer coating) to provide corrosion resistance. Its protective properties are far lower than those of electroplating, nickel plating, Dacromet plating, etc.

Abrasion resistance is generally poor: the oxide film is thin and not very hard, easily damaged by friction or scratching, exposing the substrate. It is unsuitable for surfaces subjected to severe mechanical wear.

Limited color: Only black tones (from bluish-black to deep black) can be obtained. Color variations may occur for complex workpieces or different batches of material.

Sensitive to substrate: The alloy composition, heat treatment state, and surface condition (such as rust, decarburization layer) of the steel significantly affect the color and uniformity after blackening. For example, high-alloy steel and stainless steel require completely different processes.

Special Considerations for Different Materials

| Material | Advantages (Specific) | Disadvantages (Specific) |

|---|---|---|

| Steel (Carbon Steel) | Low cost, no dimensional change, no hydrogen embrittlement, can retain oil. | Core disadvantage: Requires oil sealing for rust prevention, poor wear resistance. |

| Stainless Steel | Good decorative black appearance, retains some of stainless steel's corrosion resistance. | Complex process, difficult color control, coating may have poor wear resistance. |

| Aluminum (Black Anodized) | Prominent advantages: High hardness, wear resistance, good corrosion resistance, stable color. | Higher cost, non-conductive, process more complex than steel blackening. |

| Titanium Alloy (Anodized) | Color is functional interference color, wear-resistant, good biocompatibility. | Color may vary with viewing angle, coating is relatively thin. |

Comparison of Black Oxidation Treatment with Other Metal Surface Treatments

Black anodizing treatment (specifically for steel) occupies a unique position in the family of metal surface treatments. We systematically compare it with several of the most commonly used treatments.

| Feature | Black Oxide | Electroplating (e.g., Zinc, Nickel) | Phosphating | Powder Coating |

|---|---|---|---|---|

| Coating Nature | Chemical conversion coating | Additional metal coating | Chemical conversion coating (phosphate) | Organic polymer coating |

| Thickness/Impact on Dimensions | Almost no impact | Significant increase, affects precision | Slight increase | Significant increase |

| Corrosion Resistance | Moderate (depends on post-treatment) | Excellent | Moderate (often used as primer for painting) | Excellent |

| Appearance | Matte black | Metallic luster, various colors available | Light to dark gray | Wide range of colors and textures |

| Cost | Low | Medium to High | Low | Medium |

Frequently Asked Questions (FAQ)

Q1: How long does blackening treatment prevent rust?

A: This depends on the post-treatment and the environment. The black oxide layer alone provides minimal rust prevention and may last for a few months in a dry indoor environment. With proper oil immersion, it can typically withstand 24–72 hours or more in standard neutral salt spray testing. For outdoor or humid environments, periodic reapplication of anti-rust oil is necessary.

Q2: Can the black oxide layer peel off or fade?

A: Since it is a conversion coating with strong adhesion, it generally does not peel off entirely under normal use. However, it may gradually wear down ("fade") due to friction, eventually exposing the underlying metal color.

Q3: Can all metals undergo blackening treatment?

A: No. It is mainly suitable for iron, steel, stainless steel, copper, and zinc. Metals such as aluminum, magnesium, and titanium require entirely different processes like anodizing.

Q4: Is blackening treatment environmentally friendly?

A: Modern processes have advanced, with more eco-friendly low-temperature and nitrite-free formulations available. However, wastewater from traditional methods still requires professional treatment, making it crucial to choose suppliers that meet environmental standards.

Q5: How can I identify a high-quality black oxide workpiece?

A: Check for a uniform appearance without red or white spots; after touching, verify the presence of an oily protective film; and request salt spray test reports from the supplier when possible.