For engineers, product designers, and manufacturing enterprises, accurately estimating CNC prototype production costs is a key step in controlling project budgets and accelerating product launch cycles. However, CNC prototype pricing is not a fixed figure—two core factors, design complexity and production quantity, directly determine the final unit price. As a professional precision CNC machining provider, wsrcnc has developed a user-friendly CNC prototype cost calculator to help customers quickly obtain accurate cost estimates. This article will detail how design complexity and production quantity affect unit prices, and how to use our cost calculator to optimize your prototype production plan.

Why Do You Need a CNC Prototype Cost Calculator?

In the early stage of product R&D, many customers face the pain point of "unclear cost composition"—blindly quoting often leads to budget overruns, while inaccurate cost estimates may delay the prototype verification and mass production process. A professional CNC prototype cost calculator solves these problems by integrating core cost-influencing factors, providing transparent and reliable cost data for your project.

wsrcnc’s CNC prototype cost calculator has three core advantages:

1.High Accuracy: Integrate real-time raw material prices, machining time, labor costs, and other variables to avoid deviation between estimated and actual costs.

2. High Efficiency: Input key parameters (design drawings, material type, quantity, etc.) to get a detailed cost report in 5 minutes, no need to wait for manual quotation.

3. Transparency: Clearly display the cost composition (material cost, machining cost, surface treatment cost, etc.), helping you identify cost-saving space.

Core Factor 1: How Design Complexity Affects CNC Prototype Unit Price

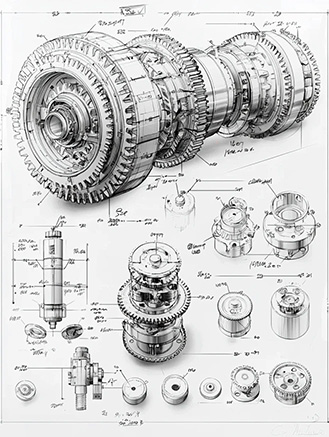

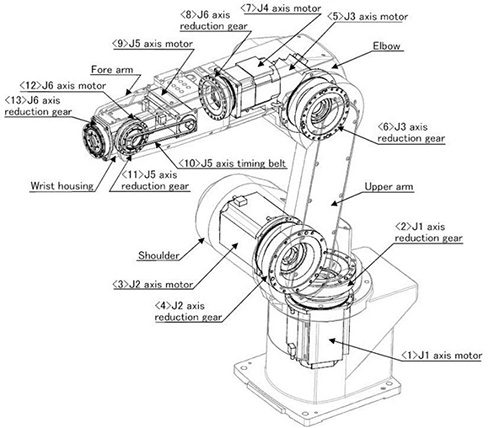

Design complexity is the most critical factor affecting CNC prototype unit price. The more complex the structure, the higher the requirements for machining precision, process difficulty, and time cost, which directly pushes up the unit price. We can break down the impact of design complexity into four dimensions:

1. Geometric Structure Complexity

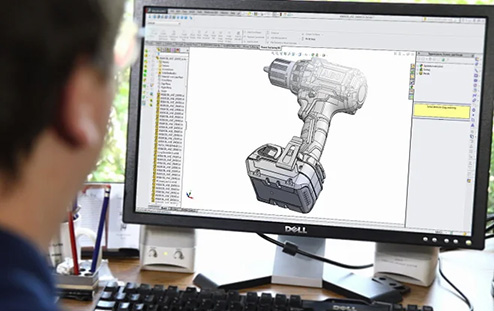

Simple structures (such as cylindrical, rectangular prototypes with no special features) can be machined with basic CNC lathes/milling machines, with short machining time and low unit price. However, complex structures—such as deep cavities, narrow slots, irregular curved surfaces, and multi-angle holes—require high-precision 5-axis CNC machining equipment and professional programming technology.

For example, a prototype with a deep cavity (depth > 50mm, diameter < 10mm) requires special tools and multi-step machining to avoid tool vibration and ensure machining accuracy, which increases machining time by 2-3 times compared to simple structures, and the unit price will also rise accordingly. At wsrcnc, our cost calculator will automatically match the corresponding machining process according to the geometric structure parameters in your design drawing, and accurately calculate the time cost.

2. Dimensional Accuracy and Tolerance Requirements

The stricter the dimensional accuracy and tolerance requirements of the prototype, the higher the machining difficulty and the more expensive the unit price. Ordinary CNC prototypes have a tolerance of ±0.05mm, which can meet most general R&D needs; while high-precision prototypes (tolerance ≤ ±0.005mm) require advanced equipment (such as high-speed CNC machining centers), precision testing tools (CMM coordinate measuring machines), and repeated debugging, which significantly increases the cost.

Taking a small CNC prototype with a diameter of 10mm as an example: the unit price for a tolerance of ±0.05mm is about $50-80, while the unit price for a tolerance of ±0.005mm will rise to $150-200. Our cost calculator will automatically adjust the cost coefficient according to the tolerance parameters you input, ensuring accurate quotation.

3. Surface Treatment Requirements

Surface treatment is an important part of CNC prototype production, and its complexity directly affects the unit price. Simple surface treatments (such as deburring, polishing) have low costs, while complex treatments (such as anodizing, electroplating, PVD coating, and spray painting) require additional processes, materials, and time.

For example, anodizing treatment (with color customization and thickness requirements) will increase the unit price by $10-30 per piece compared to ordinary polishing; PVD coating (wear-resistant and corrosion-resistant) will increase the unit price by $30-50 per piece. When using wsrcnc’s cost calculator, you only need to select the required surface treatment type and parameters, and the system will automatically calculate the additional cost.

4. Material Selection

Material cost accounts for 30%-50% of CNC prototype production cost, and the type and quality of materials directly affect the unit price. Common prototype materials include aluminum alloy (6061, 7075), stainless steel (304, 316), carbon steel, copper, plastic (ABS, POM), and special materials (titanium alloy, magnesium alloy).

The price difference between materials is huge: for example, the cost of titanium alloy material is 5-8 times that of aluminum alloy, and the unit price of a titanium alloy prototype will be significantly higher than that of an aluminum alloy prototype with the same structure. Our cost calculator integrates real-time material price data, and you can quickly compare the cost differences of different materials by switching material options.

Core Factor 2: How Production Quantity Affects CNC Prototype Unit Price

Production quantity has an inverse relationship with CNC prototype unit price—under the same design and process conditions, the larger the quantity, the lower the unit price. This is mainly due to the "fixed cost amortization" effect, and we can analyze it from three aspects:

1. Amortization of Fixed Costs

CNC prototype production has certain fixed costs, including programming time (design drawing analysis, CNC program writing), tool debugging (tool installation, parameter adjustment), and equipment setup. These fixed costs are basically unchanged regardless of the production quantity.

For example, the fixed cost of a certain prototype is $500 (programming: $200, tool debugging: $200, equipment setup: $100). If the production quantity is 10 pieces, the fixed cost amortized per piece is $50; if the quantity is 100 pieces, the fixed cost amortized per piece is only $5. This is why the unit price of small-batch prototypes (1-50 pieces) is significantly higher than that of large-batch prototypes (100+ pieces).

2. Scale Effect of Material Purchase

When the production quantity is large, enterprises can purchase raw materials in bulk, which can obtain lower purchase prices from suppliers (usually 10%-20% discount compared to small-batch purchase). This scale effect of material purchase can further reduce the unit material cost, thereby reducing the overall unit price of the prototype.

wsrcnc has long-term cooperative relationships with top material suppliers, and can obtain preferential bulk purchase prices for various materials. When you input a large production quantity in our cost calculator, the system will automatically apply the bulk material price to ensure that you get the most cost-effective quotation.

3. Optimization of Machining Efficiency

For large-batch prototype production, the machining process can be optimized (such as using automatic loading and unloading equipment, optimizing tool paths) to improve production efficiency and reduce labor and time costs. For example, small-batch production may require manual loading and unloading (1-2 minutes per piece), while large-batch production can use automatic loading and unloading systems (10-20 seconds per piece), which significantly reduces the unit time cost.

How to Use wsrcnc’s CNC Prototype Cost Calculator for Optimal Budget Control

Using wsrcnc’s CNC prototype cost calculator is simple and efficient, and you can complete the cost estimate in 4 steps. At the same time, we provide professional suggestions to help you optimize the design and quantity to control the budget:

Step 1: Input Basic Information

Enter basic project information, including prototype name, material type (aluminum alloy, stainless steel, plastic, etc.), material specifications (size, thickness, etc.), and production quantity. Our calculator supports quantity input from 1 piece to 10,000+ pieces, covering both small-batch prototypes and large-batch production.

Step 2: Upload Design Drawings

Upload your prototype design drawings (support PDF, CAD, STEP, IGES and other formats). The system will automatically analyze the geometric structure, dimensional accuracy, and tolerance requirements of the prototype, and match the corresponding machining process and cost coefficient. If you have no drawings, you can also describe the design requirements in detail (such as structure, size, tolerance) and our technical team will assist you in completing the analysis.

Step 3: Select Additional Requirements

Select additional requirements, including surface treatment (polishing, anodizing, electroplating, etc.), testing requirements (dimensional testing, performance testing, etc.), and delivery time. The system will automatically calculate the additional cost of these requirements and add them to the total cost.

Step 4: Get Detailed Cost Report

Click the "Calculate Cost" button, and the system will generate a detailed cost report within 5 minutes, including total cost, unit price, cost composition (material cost, machining cost, surface treatment cost, etc.), and production cycle. You can download the report for later reference, or adjust parameters (such as material, quantity, surface treatment) to compare different cost plans.

Professional Budget Optimization Suggestions

Optimize Design Complexity: For non-critical structural parts, appropriately relax tolerance requirements (from ±0.005mm to ±0.01mm) or simplify complex structures (such as replacing deep cavities with split structures) to reduce machining difficulty and cost.

Reasonably Plan Quantity: If your project allows, you can combine small-batch prototype orders into large-batch production to enjoy the preferential unit price of large-batch production.

Choose Cost-Effective Materials: Under the premise of meeting product performance, choose cost-effective materials (such as using aluminum alloy instead of titanium alloy for non-high-strength requirements) to reduce material costs.

Why Choose wsrcnc’s CNC Prototype Cost Calculator & Services?

As a precision CNC machining enterprise with 10+ years of experience, wsrcnc not only provides a professional cost calculator but also brings one-stop CNC prototype production services to customers, with core advantages that cannot be matched by ordinary providers:

Professional Technical Support: Our engineering team with rich experience can provide design optimization suggestions according to your cost budget, helping you balance cost and performance.

Strict Quality Control: Adopt ISO 9001 quality management system, implement full-process quality inspection (raw material inspection, machining inspection, finished product inspection), and ensure that the prototype meets your design requirements.

Efficient Delivery: Equip with advanced CNC machining equipment and automatic production lines, and promise to deliver small-batch prototypes within 3-5 days and large-batch production within 7-15 days.

Transparent Pricing: No hidden fees, the cost report generated by the calculator is consistent with the final actual cost, ensuring that you can control the budget with peace of mind.

Try wsrcnc’s CNC Prototype Cost Calculator for Free Now!

Accurate cost estimation is the first step in successful prototype production. wsrcnc’s CNC prototype cost calculator helps you quickly grasp the impact of design complexity and production quantity on unit price, and provides optimal budget control solutions. Whether you are in the early stage of product R&D or preparing for mass production, we can meet your needs with professional services and cost-effective prices.

Click [Calculator Entry Link] to try wsrcnc’s CNC prototype cost calculator for free, or contact our sales team via email ([your email address]) or phone ([your phone number]) to get one-on-one professional consultation. Let wsrcnc be your reliable partner in CNC prototype production, and help your product quickly launch the market!

Exclusive Benefit: New customers who use the cost calculator and place an order will enjoy a 10% discount on their first CNC prototype order! Contact wsrcnc now to seize the benefit!