Introduction: Why is Slot Milling So Important?

In modern machining, slot milling is a critical process widely used in industries such as automotive, aerospace, and mold manufacturing. Whether it's cutting keyways for gears, T-slots for mechanical parts, or cooling grooves for electronic devices, slot milling plays a vital role.

But what exactly is slot milling? How does it differ from conventional milling? How do you choose the right tools and machining parameters? This guide provides a comprehensive breakdown—from basic principles to real-world applications!

Fundamentals of Slot Milling

1. What is Slot Milling?

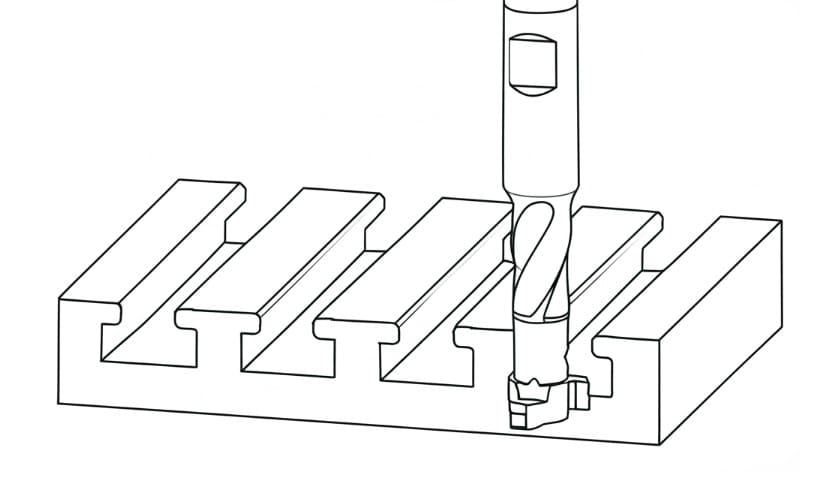

Slot milling is a machining process that uses rotating cutters to create grooves in a workpiece, commonly used for keyways, T-slots, dovetail slots, and relief grooves.

2. Slot Milling vs. Conventional Milling: Key Differences

| Comparison | Slot Milling | Conventional Milling |

|---|---|---|

| Purpose | Specialized for groove cutting | General-purpose (surfaces, contours) |

| Tooling | Dedicated slot cutters (e.g., keyseat cutters, T-slot mills) | Standard end mills, face mills |

| Cutting Method | Side milling, groove width = tool diameter | Multi-directional, flexible machining |

| Precision | Tight tolerances (width, depth, position) | Less critical |

3. Core Parameters of Slot Milling

Tool Diameter = Groove width (e.g., a 10mm cutter for a 10mm slot)

Cutting Depth (Axial) – Affects efficiency and tool life

Feed Rate (Chip Load) – Determines surface finish

Common Types of Slot Milling & Applications

1. Keyway Milling

Use Case: Shaft-key connections (gears, couplings)

Tool: Keyseat cutter (2 flutes, can plunge vertically)

Key Feature: High precision, prevents loosening

2. T-Slot Milling

Use Case: Machine tables, fixture slots

Tool: T-slot cutter (requires roughing first, then finishing)

Key Feature: Multi-step process to avoid tool breakage

3. Dovetail Slot Milling

Use Case: High-precision sliding mechanisms (e.g., machine guides)

Tool: Dovetail cutter (angled profile)

Key Feature: Demands tight fit tolerance

4. Face Grooving

Use Case: Sealing grooves, snap-ring slots

Tool: Thin-blade grooving tool (minimal overhang)

Key Feature: Low feed rates for deep, narrow slots

Best Practices for Slot Milling

1. How to Choose the Right Slot Mill?

Material: Carbide (high performance) vs. HSS (cost-effective)

Flute Count: 2 flutes (better chip clearance) vs. 3-4 flutes (stability)

Coating: TiAlN (heat-resistant) or DLC (low friction)

2. 3 Key Tips for Optimizing Cutting Parameters

RPM Formula: (Cutting Speed × 1000) ÷ (π × Tool Diameter)

Feed Rate (IPM): Chip Load × Flutes × RPM

Depth of Cut: Roughing (0.5–1× tool diameter) vs. Finishing (0.1–0.3mm)

3. Avoiding Common Issues

Oversized Slots → Check tool wear/machine rigidity

Poor Surface Finish → Reduce feed rate, use coolant

Tool Chipping → Decrease depth, avoid interrupted cuts

4.Future Trends in Slot Milling

With advancements in high-speed machining (HSM) and smart CNC systems, slot milling is evolving toward:

Adaptive Machining (auto-adjusted parameters)

Hybrid Processes (e.g., turn-mill machines)

5-Axis Slotting (complex contour grooves)

Mastering slot milling boosts productivity and reduces costs—start optimizing your process today!

Engage With Us

What’s your biggest challenge in slot milling?