Discover the ultimate guide to sheet metal fabrication: a detailed explanation of key processes including cutting (laser, punching, plasma), bending, and forming. Learn how to choose the best materials and processes for your manufacturing project to improve quality and control costs. Get expert insights.

What is Sheet Metal Fabrication? A Guide to Manufacturing Processes: Cutting, Bending, and More

Keywords: Sheet metal fabrication, Sheet metal manufacturing, Laser cutting, Bending, Metal sheet fabrication

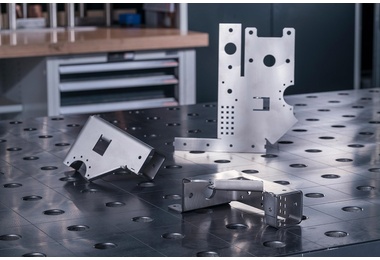

In every corner of modern manufacturing—from server chassis in data centers to medical equipment in hospitals, from household kitchen appliances to precision components in aerospace vehicles—there is a common manufacturing foundation: sheet metal fabrication. It is both an art and a science of transforming flat metal sheets into three-dimensional functional parts through a series of precise processes.

If you are looking for a comprehensive, easy-to-understand, and professional guide to sheet metal manufacturing to help you make more informed decisions, you have come to the right place. This article will take you deep into every aspect, from basic concepts to cutting-edge processes.

What is Sheet Metal Fabrication?

Sheet metal fabrication is a comprehensive cold-working manufacturing process for thin metal sheets with a thickness of less than 6mm. The main processes include cutting, blanking, punching, bending, forming, riveting, welding, and assembly. The final products, known as sheet metal parts, are characterized by their light weight, high strength, good conductivity, low cost, and suitability for mass production.

Commonly used materials include:

Cold-rolled steel (SPCC): Smooth surface, easy to form, often used for electrical enclosures and cabinets.

Stainless steel: Corrosion-resistant, aesthetically pleasing, used in food machinery and medical equipment.

Aluminum: Lightweight, corrosion-resistant, good electrical conductivity, used in aerospace and electronics industries.

Brass and copper: Primarily used for electrical components and decorative parts.

Detailed Explanation of Core Sheet Metal Manufacturing Processes

1. Cutting: Precise Separation from Whole Sheet to Part

Cutting is the first step in sheet metal manufacturing and is critical for determining precision.

Laser cutting: Currently the most mainstream and high-precision cutting method. It uses a high-power-density laser beam to irradiate the material, causing it to melt and vaporize rapidly. Advantages: Extremely high precision (±0.1mm), narrow kerf, no tool wear, ability to cut complex graphics, and high automation. Ideal for prototypes and small-batch production.

CNC punching: Uses programming to control molds to punch holes or shapes into the sheet metal. Advantages: Suitable for high-volume processing of standard shapes (e.g., square holes, mesh panels), fast speed, and ability to complete punching and shallow forming in one step. Less efficient for complex graphics compared to laser cutting.

Plasma cutting: Uses a high-temperature plasma arc to melt the metal and blow it away with a high-speed airflow. Advantages: Suitable for cutting thicker medium-carbon steel and aluminum plates (up to 50mm or more), fast speed. Disadvantages: Large heat-affected zone, lower precision and cut surface finish compared to laser cutting.

Waterjet cutting: Uses an ultra-high-pressure water stream (mixed with abrasive) to cut materials. Advantages: Cold cutting, no heat-affected zone, can cut any material (metal, stone, glass). Disadvantages: Relatively slow speed and higher operating costs.

2. Bending: Transforming 2D Sheets into 3D Forms

Bending is the process of bending a cut flat sheet into the desired angle using a press brake and specialized tools (punch and die).

Key concepts:

Bend radius: The size of the inner radius affects the strength and appearance of the product.

K-factor: A coefficient that calculates the material stretching at the bend when flattening sheet metal, which is core to accurately calculating the blank size.

Considerations: The bending sequence is crucial. An incorrect sequence may cause tool interference or make bending impossible. Experienced engineers design optimal bending process paths.

3. Forming: Creating Complex Shapes Beyond Simple Bending

Forming processes are used to create more complex geometries.

Stamping: Uses large presses and molds to perform deep drawing, punching, embossing, etc., on sheets.

Rolling: Gradually bends metal sheets into arcs or cylinders through a set of rollers, such as ventilation ducts.

Press riveting: Pre-punches holes in the sheet and then uses a press riveting machine to firmly press nuts or studs into the holes, providing threaded connections for subsequent assembly.

4. Joining and Assembly: Integrating Parts into the Final Product

Individual parts need to be combined using joining techniques.

Welding: The strongest joining method, common types include TIG welding, MIG welding, and spot welding. Welding leaves marks that often require grinding.

Riveting: Uses rivets to join parts, suitable for connecting different materials, and is non-removable.

Threaded connections: Use screws, bolts, and press-in nuts, allowing for disassembly and repair, and are the most common method used in modern equipment enclosures.

5. Surface Treatment: Enhancing Appearance, Durability, and Functionality

The final step is surface treatment of the product to achieve corrosion resistance, aesthetics, and special functions.

Powder coating: Powder paint is adsorbed electrostatically and cured at high temperature. The coating is durable, offers many color options, and is environmentally friendly.

Plating: Such as zinc plating (rust prevention), chrome plating (aesthetic and wear-resistant), nickel plating.

Anodizing: Mainly used for aluminum, creating a wear-resistant and corrosion-resistant oxide layer that can be dyed in various colors.

Brushing/Polishing: Treats the metal surface to obtain specific textures and gloss.

How to Choose the Right Sheet Metal Fabrication Service Provider?

When choosing a partner, consider the following:

Technology and equipment: Does they have advanced laser cutting machines and high-precision press brakes? The age and brand of the equipment determine its processing capabilities.

Experience and expertise: Can engineers provide DFM (Design for Manufacturability) analysis to optimize your design for cost and time savings?

Quality system: Is there a complete quality control process (e.g., ISO 9001 certification)? Can they provide full inspection reports?

Capacity and delivery: Can they meet your production volume and delivery time requirements?

Comprehensive services: Do they offer one-stop services from material procurement and processing to assembly and surface treatment?

WSR CNC: Your Trusted Sheet Metal Manufacturing Partner

At WSR CNC, we possess world-class Trumpf laser cutting machines, multiple CNC bending centers, and complete welding, riveting, and surface treatment production lines. Our team of engineers is proficient in sheet metal DFM and is ready to provide design optimization suggestions to ensure the manufacture of top-quality sheet metal products with the highest efficiency and most competitive costs.

Whether you need a single prototype or million-level mass production, we can turn your ideas into reality.

Contact us now for a free design evaluation and quote!