If you've ever experienced tap breakage, subpar thread quality, or struggled with tapping in hard materials, you know: threading is far from easy. Thread milling is precisely the solution. Once you understand its logic, you'll likely find that there's no going back to traditional tapping.

Unlike traditional tapping, thread milling uses a tool with a diameter smaller than the hole diameter. This means you can produce both internal and external threads with a single tool, and easily switch between left-hand and right-hand threads simply by adjusting the tool path direction—a flexibility unmatched by tapping.

The advantages of thread milling lie not only in flexibility but also in precision and reliability. It delivers higher thread strength, smoother surface finish, and significantly reduces the risk of tool damage—particularly when working with challenging materials like stainless steel and titanium alloys. For this reason, thread milling has become the process of choice in demanding industries such as aerospace, automotive manufacturing, and medical devices.

However, understanding the process is crucial, as is understanding its purpose. Understanding the value of thread milling is only the first step; mastering its correct application is crucial. From selecting the right tool, determining the thread fit, to programming precise toolpaths, every step impacts the quality and consistency of the final thread.

Next, we'll delve into practical applications to identify the key elements of thread milling success and common misconceptions, helping you truly master this technique and transform it into stable, efficient productivity.

What is the Definition of Thread Milling?

Thread milling is an advanced threading process that uses a rotating tool to gradually create a precise thread profile by controlling circular motion in the XY plane while simultaneously performing linear movement along the Z axis (known as "helical interpolation"). With each revolution of the tool, the tool precisely moves axially by a distance equal to the thread pitch, resulting in a consistent and accurate thread profile on workpieces of varying diameters.

Compared to traditional tapping, thread milling's core advantage lies in its flexibility and precision. Because the tool diameter can be smaller than the thread hole diameter, a single thread milling cutter can produce a variety of internal and external thread sizes, easily switching between right-hand and left-hand threads. This method also allows for precise control of thread depth and pitch diameter, making it particularly suitable for applications with stringent tolerances.

During the machining process, the tool only partially and stage-by-stage participates in the cutting process, significantly reducing machining torque and cutting heat while also significantly improving chip evacuation. Therefore, thread milling is particularly suitable for difficult-to-machine materials such as stainless steel, titanium alloys, and other heat-resistant alloys. Thread milling cutters, typically made of solid carbide, combine high rigidity and wear resistance, ensuring long life and excellent thread surface quality across a wide range of hole diameters and operating conditions.

The History of Thread Milling

Thread milling is a unique process in CNC machining, boasting both historical heritage and modern value. Its technological roots date back to the 1960s, when CNC systems began to incorporate basic helical interpolation. By controlling the tool's circular motion while simultaneously feeding along the Z-axis, CNC thread machining was a fundamental advancement. Despite limitations in programming capabilities and machine tool performance at the time, this early stage of thread milling laid an important foundation for subsequent developments.

The process truly matured and achieved large-scale industrial application in the 1990s. The widespread adoption of three-axis CNC machine tools and breakthroughs in tool technology, particularly indexable thread milling cutters, significantly improved machining durability and adaptability. These new tools enabled manufacturers to efficiently produce internal and external threads in a variety of materials, significantly improving thread surface quality and dimensional accuracy.

In the 21st century, solid carbide thread milling cutters and specialized tools have become standard equipment in modern manufacturing. Thread milling offers irreplaceable advantages when addressing challenges such as high-precision tolerances, unique thread profiles, or deep-hole threads difficult to achieve with traditional tapping. This technology continues to advance towards higher precision, improved chip control, and greater material adaptability, meeting increasingly complex manufacturing needs

A Revolution in Threading: Thread Milling Technology Explained

Thread milling achieves high-precision, geometrically consistent threads by precisely controlling the coordination of a rotating tool and programmed axial motion. During this process, the tool performs circular interpolation in the X and Y planes while simultaneously feeding at a constant speed along the Z axis. These three elements work together to form a helical interpolation path. With each revolution of the tool, it precisely moves one pitch in the Z axis, enabling high-precision control of the thread profile, diameter, and depth. This approach is suitable for a variety of internal and external thread machining needs.

Before cutting begins, the tool must fully enter the thread base. To reduce cutting impact and ensure thread quality, a circular entry and exit path strategy is recommended. For example, a 90-degree circular entry can be combined with a coordinated Z-axis movement of one-quarter the pitch. This approach effectively avoids sudden load changes, protects the integrity of the thread profile, and extends tool life.

Thread milling cutters are primarily categorized into single-flute and multi-flute types. Single-flute milling cutters cut tooth by tooth, reducing milling forces and making them suitable for deep threads or difficult-to-machine materials. They are particularly beneficial for chip evacuation and vibration control. Multi-flute milling cutters, with their larger number of teeth, can complete thread formation in a single pass, significantly improving machining efficiency when conditions permit. The choice of tool type requires a comprehensive consideration of factors such as the workpiece material, thread specification, and production volume.

Thread milling requires a CNC machine tool with three-axis helical interpolation. Using a four- or five-axis machine tool further expands machining capabilities, such as milling complex structures like the tapered threads required for NPT connectors.

Common CNC Thread Milling Techniques

In CNC machining, thread milling relies heavily on precise programming, tool path planning, and coordinated motion between the machine's axes. The core of this process is helical interpolation, where the tool simultaneously advances along the Z axis at a rate of one pitch per revolution while moving in a circular motion in the X and Y planes, resulting in the precise production of internal or external threads.

A typical G-code program uses G02 (clockwise) or G03 (counterclockwise) commands in conjunction with Z-axis movement to create a helical path. For example:

G03 X0 Y0 Z-0.125 I0 J0.5 F20

This command controls the tool to descend in a counterclockwise spiral, feeding 0.125 units per revolution in the Z axis to form the thread.

The direction of the tool path directly impacts chip control and surface quality. Climb milling (where the tool rotates in the same direction as the feed) is generally preferred for carbide tools, resulting in smoother thread finishes; conventional milling can improve tool life in some soft materials. When machining tapered threads such as NPT threads, using a downward interpolation strategy helps push chips forward of the tool and out of the hole, preventing chip retention.

Modern CAM systems can automatically generate optimized paths with lead-in and lead-out arcs to effectively avoid tool marks at the start and end of the thread. With specialized plug-ins, operators can flexibly adjust parameters such as spindle speed, feed rate, and pitch diameter offset to accommodate different materials, thread specifications, and production cycles, achieving a highly adaptable threading process.

Analysis of Entry and Exit Strategies and Path Planning for Thread Milling

To ensure smooth tool engagement, programming should begin with a circular entry slightly below the thread's minor diameter. This path design allows for a smooth buildup of cutting forces, effectively avoiding compression and friction at the thread crest, while also reducing tool deflection due to impact.

To optimize the entry process, it is recommended to include a radial relief (typically 10% of the thread pitch) before the tool accelerates to the normal cutting feed rate. This relief significantly reduces side loads on the cutter teeth, enabling a softer entry and improving surface quality at the start of the thread.

During the exit phase, common methods include reverse helical exit or radial retraction. Reverse helical retraction reverses the original path, helping to remove chips; radial retraction rapidly exits the workpiece surface using a vertical or circular path. Both methods effectively prevent chip accumulation at the exit and prevent the tool from scratching the machined thread.

Material Application Guide for Thread Milling: Key Material Selection Considerations from Aluminum Alloys to High-Temperature Alloys

Thread milling is a highly adaptable machining process with applications across a wide range of metals, plastics, and composites. This technology is particularly well-suited for high-precision manufacturing applications such as aerospace and medical devices, meeting the stringent tolerances of internal and external threads on complex parts. The choice of material directly influences tool configuration, programming strategy, and cutting parameters.

For difficult-to-cut materials such as stainless steel, titanium alloys, and tool steels with a hardness exceeding 45 HRC, solid carbide thread milling cutters with a wear-resistant coating are recommended. These tools maintain high hardness and stability even at high temperatures, making them suitable for long-term machining and ensuring consistent thread quality. For soft materials such as aluminum and brass, high-speed steel tools are adequate and are particularly cost-effective in small-batch production.

When machining sticky, ductile materials such as plastics or soft copper, a high-helix angle cutter is recommended to improve chip evacuation and prevent chip sticking. Using mist cooling effectively controls cutting temperatures, reduces workpiece thermal deformation, and maintains thread pitch diameter and fit accuracy.

When machining high-strength, high-temperature alloys like Inconel and Cobalt-Cr, conservative machining strategies are often necessary, such as reducing feed per tooth and performing multiple cuts to distribute the cutting load and extend tool life. Solid carbide tools excel in these applications. Their high rigidity effectively reduces tool deflection during blind hole machining, ensuring the integrity of the thread's form and function.

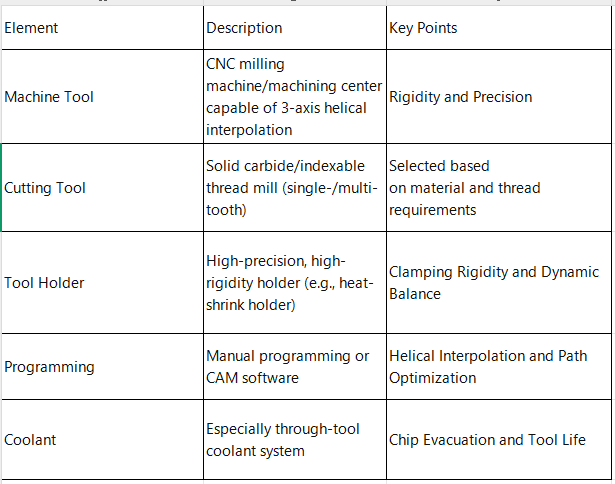

Thread Milling Essentials: A Complete Analysis of Machine Tools, Tools, and Auxiliary Tools

The core requirement for thread milling is a machine tool with three-axis linkage, capable of synchronously controlling the X, Y, and Z axes for helical interpolation (e.g., G02/G03 commands). A minimum three-axis CNC milling machine or machining center is required. Its rigidity, positioning accuracy, and repeatability directly determine the quality of the thread. For complex machining scenarios such as tapered pipe threads (such as NPT), beveled threads, or interference avoidance, the multi-axis collaboration provided by four-axis or five-axis machining centers is essential for greater flexibility and process adaptability. Tooling

Thread milling cutters are key tools for direct cutting tasks. Their selection requires comprehensive consideration of factors such as workpiece material, thread specifications, and production batch size.

Structurally, they can be divided into three categories: solid carbide milling cutters offer high rigidity and excellent precision, suitable for most materials and small to medium-volume production. Indexable insert milling cutters, which can be replaced with inserts, offer economical machining and are particularly suitable for large-diameter threads and large-volume production. Welded carbide milling cutters offer both cost-effectiveness and are commonly used for machining general steel and cast iron.

Based on tooth shape, thread milling cutters can be divided into two categories: single-flute thread milling cutters offer low cutting forces and smooth chip evacuation, specifically for deep threads, difficult-to-machine materials (such as stainless steel and titanium alloys), and blind hole threads. Multi-flute thread milling cutters offer high efficiency, can form threads in a single pass, and are often used in applications with stable working conditions and easy-to-cut materials.

Simply put, successful thread milling requires a qualified CNC machine, a suitable thread milling cutter, a precision toolholder, and correct programming. All four are essential.

The Core Advantages of Thread Milling

The core advantages of thread milling lie in its exceptional processing flexibility and enhanced safety. Compared to traditional tapping, a single thread milling cutter can produce internal and external threads of varying diameters and pitches, even left-hand and right-hand threads, achieving true "one tool for multiple uses" and significantly reducing tool inventory costs. Furthermore, its side cutting method virtually eliminates the risk of tap breakage, making it especially safe and reliable when machining large-diameter, deep-hole, or blind-hole threads.

Furthermore, thread milling significantly improves thread quality and processing efficiency. CNC programming allows for precise control of thread dimensions, resulting in superior surface finish and consistency. The high-speed cutting capabilities of carbide tools, combined with effective chip breaking and evacuation, enable excellent performance in difficult-to-machine materials such as stainless steel and titanium alloys, resulting in overall efficiency far exceeding that of traditional tapping.

Disadvantages of Thread Milling

High Equipment Cost: Thread milling must be performed on a CNC machining center that supports three-axis linkage (helical interpolation). This requires specific machine programming and control systems, and the equipment investment is significantly higher than that required for drilling machines or simple lathes for conventional tapping.

Complex Programming: Compared to traditional tapping (which typically requires only a single G84 command), thread milling requires complex helical interpolation programs (G02/G03), requires more complex path planning (such as entry and exit), is more dependent on CAM software, and requires a higher level of operator skill.

Large Initial Investment: High-quality carbide thread milling cutters are expensive, often several times the price of a tap. While a single tool has a wide range of applications, the initial purchase cost is high.

Unsuitable for extremely shallow blind holes: The tool base requires sufficient space for the circular entry and exit motions. In very shallow blind holes, there may not be enough space to complete these paths, resulting in an incomplete thread.

Less obvious advantages for small threads: Thread milling cutters inherently present significant challenges and lack rigidity for small threads (e.g., under M2), making them less efficient and economical than traditional tapping.

Common Thread Milling Applications

Thread milling, with its high precision, exceptional flexibility, and improved tool life, has become the preferred process in many high-end manufacturing fields. This technology is particularly well-suited for machining difficult-to-cut materials (such as titanium alloys and stainless steel), applications with tight tolerances, or requiring specialized thread profiles (such as trapezoidal threads). Whether machining aerospace-grade titanium alloy components or precision stainless steel parts for medical devices, thread milling provides the necessary machining adaptability and dimensional accuracy to effectively meet complex and demanding manufacturing requirements.

The following are six key industries and their typical thread milling applications:

Aerospace: Used for machining high-reliability threads in high-strength titanium alloys and complex structural components.

Medical: Producing clean, contamination-free precision threads for surgical tools and implants.

Automotive: Particularly for efficient, high-strength threading of core components such as engines and transmissions.

Energy Equipment: Processing large, high-strength connecting threads on large, pressure-resistant equipment such as those used in oil and nuclear power plants.

Mold Manufacturing: Solving the challenges of thread machining on heat-treated, high-hardness mold steel.

Precision Electronics: Meeting the demand for small, highly consistent threads in precision instruments and electronic products.

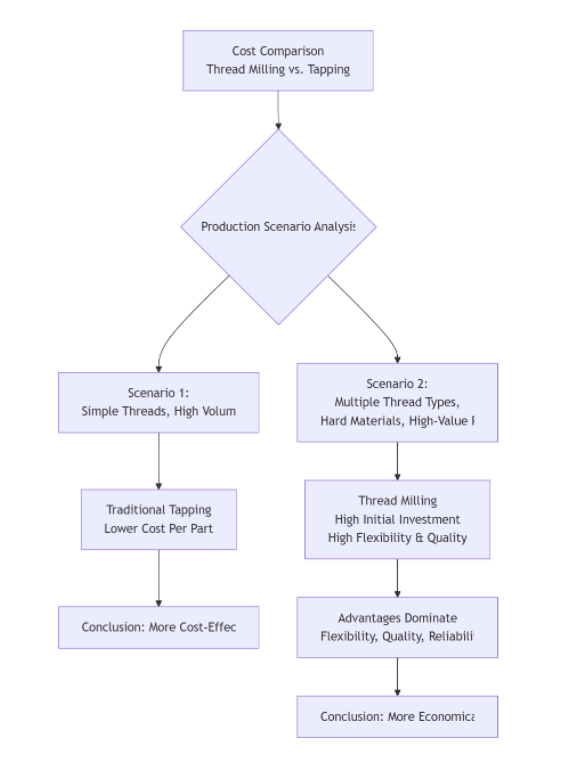

The cost of thread milling depends on many factors and cannot be simply priced. Key costs include:

Equipment: A three-axis CNC machining center with helical interpolation is required.

Tooling: A high-quality thread milling cutter can cost hundreds to thousands of yuan and requires a high-precision toolholder.

Programming: CAM software and specialized programming skills are required.

The cost depends primarily on machine tool labor costs and tool wear.

Detailed Comparison Table

| Characteristic | Thread Milling | Tapping |

|---|---|---|

| Basic Principle | Uses a rotating cutter to "mill" threads via 3-axis helical interpolation on a CNC machine. | Uses a tap with multiple flutes to "tap" threads through rotational cutting or forming. |

| Flexibility | Very High. One tool can create internal/external threads of different diameters, pitches, and handings (right/left). | Very Low. One tap is dedicated to one specific thread size and pitch. |

| Process Safety | High. The robust tool cuts laterally, making it highly resistant to breakage and preventing workpiece damage. | Low. Taps are brittle and can break easily, especially in blind holes, often scrapping the part. |

| Precision & Quality | High. CNC compensation allows for precise size control and excellent surface finish with minimal burrs. | Moderate. Quality depends on tap condition; cutting taps can leave burrs, especially in ductile materials. |

| Chip Evacuation | Excellent. Produces small, broken chips that are easily flushed away, ideal for blind holes. | Poor. Generates long, continuous chips that can clog in blind holes, leading to tap breakage. |

| Efficiency | Slower setup, faster cutting. Complex programming is offset by high cutting speeds and reduced tool changes; ideal for high-mix production. | Faster setup, slower cutting. Simple programming (often one G-code line) but slower cutting speeds; ideal for high-volume single-thread production. |

| Equipment Requirements | High. Requires a 3-axis CNC machining center with helical interpolation capability. | Low. Can be performed on basic drill presses, tappers, or simpler CNCs. |

| Tooling Cost | High per-tool cost (carbide mill), but "one tool does many jobs," potentially reducing total inventory cost. | Low per-tool cost, but requires a large inventory of taps for different sizes, increasing total cost. |

| Suitable Materials | Very Broad, excels with stainless steel, titanium, and other difficult-to-machine materials. | Limited. Challenging with high-strength, gummy materials. |

| Special Capabilities | Can machine large diameters, threads on inclined surfaces, and partial threads (e.g., at edges). | Limited to standard threads in standard locations. |