Struggling to choose the right material for your CNC project? This guide provides a complete analysis of the properties, costs, and applications of materials like aluminum, stainless steel, titanium, and engineering plastics to help you make the best decision and reduce manufacturing costs.

Why Material Choice is Critical

In product development and manufacturing, have you ever faced these dilemmas?

The prototype looks perfect but fails under testing due to insufficient strength?

Small-batch production goes smoothly, but material costs spiral out of control for large volumes?

Parts fail prematurely in specific environments (e.g., high temperature, moisture)?

Choosing the wrong material isn't just a waste of money; it wastes precious time and market opportunities. Selecting the correct material is key to balancing performance, cost, manufacturability, and appearance. This article will be your ultimate guide to making an informed material choice for your next CNC project.

Core Factors for Selecting CNC Materials

Before diving into specific materials, ask yourself these questions to form your selection framework:

Functional Requirements: What mechanical strength, hardness, and wear resistance must the part withstand?

Operating Environment: Will it be exposed to corrosive chemicals, moisture, or high/low temperatures?

Budget & Volume: Is it for a prototype or mass production? Which takes priority: material cost or machining efficiency?

Post-Processing & Appearance: Are surface treatments like anodizing, plating, or painting required?

Regulations & Safety: Are food-grade, medical-grade certifications, or biocompatibility needed?

In-Depth Showdown of Popular CNC Machinable Materials

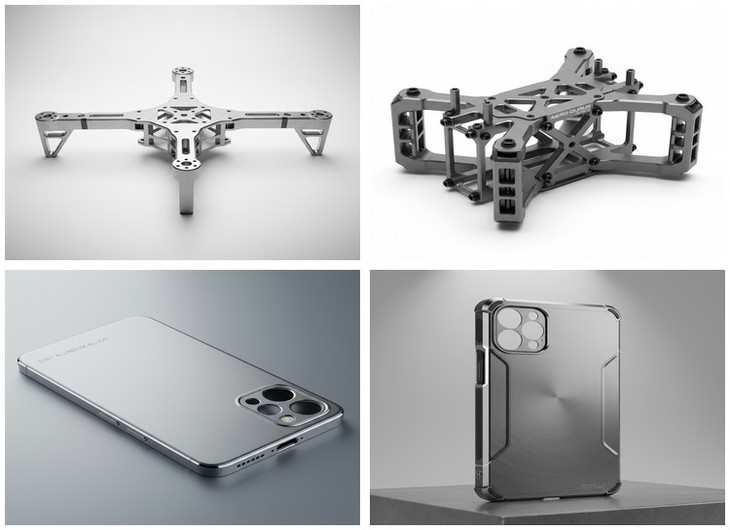

1. Aluminum Alloys – The Top Choice for Lightweighting and Cost-Effectiveness

Key Advantages: Light weight, high strength-to-weight ratio, excellent machinability, good corrosion resistance, low cost.

6061: The "All-Rounder," excellent overall properties, suitable for most structural components, brackets, and enclosures.

7075: The "Strength King," strength comparable to steel, used in aerospace and high-performance sports equipment.

5052: Outstanding corrosion resistance, often used in marine applications and sheet metal parts.

Machining Tip: Excellent machinability, high cutting speeds, good surface finish.

Ideal For: Drone frames, automotive parts, electronic enclosures, consumer electronics, heat sinks.

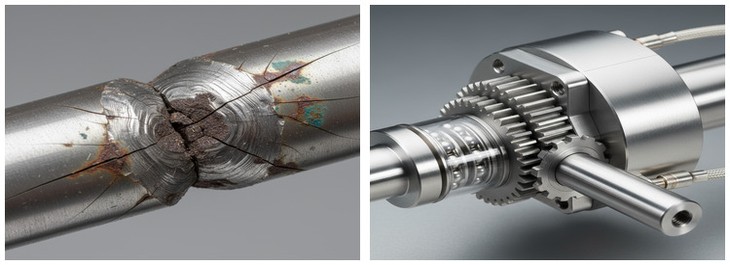

2.Stainless Steel – The Champion of Strength and Corrosion Resistance

Key Advantages: High strength, exceptional corrosion resistance, heat resistance, aesthetically pleasing.

304: General-purpose austenitic stainless steel, good corrosion resistance, used for kitchenware, piping, structural components.

316: Superior corrosion resistance (especially against chlorides), used in medical, marine, and chemical processing equipment.

303: With added sulfur, easy to machine, suitable for high-speed machining, used for shafts and gears.

304L: Ultra-pure, excellent biocompatibility, primarily for medical implants.

Machining Tip: More difficult to machine than aluminum, higher tool wear, requires ample coolant.

Ideal For: Surgical instruments, food processing machinery, chemical pumps/valves, offshore platform fittings.

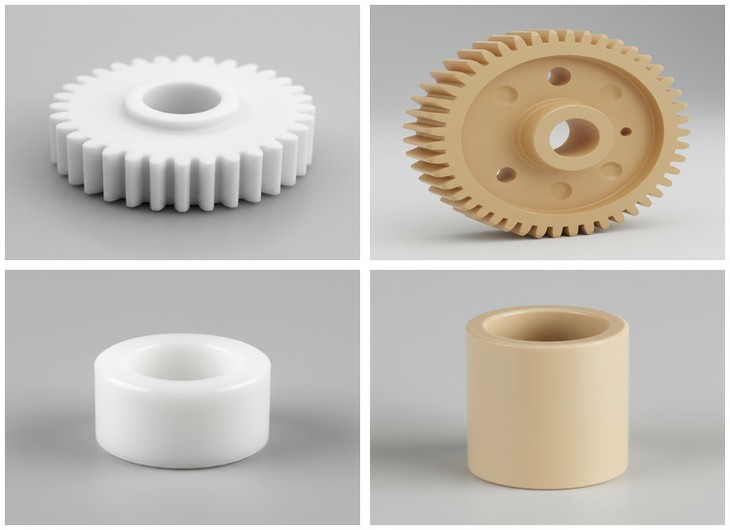

3. Engineering Plastics – The Experts in Insulation, Corrosion Resistance, and Self-Lubrication

Key Advantages: Light weight, electrical insulation, chemical resistance, self-lubricating, noise reduction.

POM (Acetal / Delrin): "Acetal," mechanical properties similar to metal, wear-resistant, dimensionally stable, exceptionally smooth surface finish after machining, ideal for gears and bearings.

Nylon (PA): Tough, wear-resistant, fatigue-resistant, commonly used for gears, pulleys, and insulating parts.

PC (Polycarbonate): High transparency, high impact strength, used for face shields, windows, and lamp housings.

PEEK: High-performance specialty plastic, heat-resistant, high strength, excellent chemical stability, expensive, used in aerospace and medical implants.

Machining Tip: Plastics have low thermal conductivity; control cutting heat to prevent material softening or melting.

Ideal For: Insulating components, low-friction bushings, food processing equipment, transparent housings.

4.Titanium Alloys – The Performance Beast for High-End Applications

Key Advantages: Extremely high strength-to-weight ratio, top-tier corrosion resistance, biocompatibility.

Machining Tip: Very difficult to machine, poor thermal conductivity, prone to work hardening, requires specialized tools and parameters.

Ideal For: Aerospace compressor blades, medical implants (artificial joints), racing connecting rods.

5. Other Metals

Brass: Easy to machine, aesthetically pleasing, highly conductive, and corrosion-resistant. Commonly used in valves, pipes, decorative parts, and electronic components.

Copper: Excellent electrical and thermal conductivity, but soft and prone to sticking to knives, making machining difficult. Commonly used in electrical components and radiators.

Magnesium alloys: Lighter than aluminum, but flammable, requiring special care in machining. Used in lightweight aerospace and automotive parts.

Nickel alloys (such as Inconel 718): Superalloys with high-temperature and corrosion resistance, but extremely difficult to machine. Used in jet engines and gas turbines.

6. Other Plastics

Acrylic (PMMA): Excellent clarity, easy to cut and polish, used for signs, models, and light boxes.

PTFE (Teflon): Extremely low friction, strong chemical resistance, and high-temperature resistance, but soft and prone to deformation during processing.

Composites and Other Materials

Carbon Fiber Reinforced Plastic (CFRP): Extremely high strength-to-weight ratio and excellent rigidity, but very wear-resistant to cutting tools, requiring specialized tooling and processing. Used in aerospace, racing, and high-end sports equipment.

Glass Fiber Reinforced Plastic (GFRP): Similar in performance to carbon fiber but slightly inferior, at a lower cost.

Wood: Suitable for CNC milling (wood carving) and turning, used for prototypes, models, furniture, and artwork.

Foam: Used for models, prototypes, packaging, and sculpture.

Quick Selection Guide – Make Your Decision with One Table

| Your Requirement | Recommended Materials (Priority from high to low) |

|---|---|

| Lightweight + Cost-Effective | Aluminum Alloy (6061) → Engineering Plastics (POM) |

| Maximum Strength + Corrosion Resistance | Stainless Steel (316/304) → Titanium Alloy (TC4) |

| Wear Resistance + Self-Lubrication | POM → Nylon → Phosphor Bronze |

| Transparent Parts | PC → Acrylic (PMMA) |

| High-Temperature Environment (>200°C) | Titanium Alloy → PEEK → Stainless Steel |

| Medical Implants | Titanium Alloy → 316L Stainless Steel → PEEK |

| Prototyping (Low Cost) | Aluminum Alloy (6061) → ABS Plastic |

Can't Find the Answer? Let Our Experts Help You!

Materials science is vast, and every project is unique. If you still have questions after reading this guide, or if your project faces challenges like extreme environments, special regulations, or demanding cost-performance trade-offs, you need more than a guide – you need a professional manufacturing partner.

Wsrcnc offer free expert material selection consulting! Our engineering team has over 15 years of CNC machining experience and can provide the most economical and reliable material solution for your project.

Act now and build success into your project!

Click here for free material selection advice

Upload your 3D drawing for an instant quote and expert opinion.