In-Depth Analysis of China's Top 10 Injection Molding Companies: How to Choose the Best Partner in 2026

Introduction: Are you looking for a reliable, high-quality injection molding partner for your project but struggling to choose among China's numerous suppliers? This article will provide you with a systematic overview of nine leading injection molding companies in China and an authoritative selection guide to help you make the optimal decision based on key dimensions such as mold capabilities, production scale, industry expertise, and cost control.

5 Core Considerations for Choosing an Injection Molding Company

Before diving into specific companies, let's first clarify the key criteria for evaluating an injection molding supplier. These factors will directly impact the quality, cost, and delivery timeline of your project.

1. Technology and Mold Capabilities

Molds are the core of injection molding. An excellent supplier should possess in-house design and manufacturing capabilities for precision molds, be able to provide professional DFM (Design for Manufacturing) analysis, and optimize product structure, reduce costs, and shorten lead times from the source. Pay attention to the technical level of their mold department, the software used (e.g., UG, Pro/E), as well as mold lifespan and precision.

2. Equipment and Production Capacity Scale

Advanced and well-maintained equipment is the guarantee of quality and efficiency. Understand the brands of injection molding machines in the factory (e.g., Haitian, Zhenxiong, Engel, Demag), the range of clamping force (whether it covers the small 50T to large 3000T+ required for your product), whether they are equipped with electric injection molding machines (more energy-efficient and precise), and the level of automation (robotic arms, automated production lines).

3. Industry Experience and Qualifications

Different industries have vastly different requirements for injection molded parts. Medical injection molding requires sterile environments and biocompatible material certifications; automotive injection molding focuses on weather resistance, strength, and dimensional stability; consumer electronics injection molding pursues high-gloss finishes, ultra-thin walls, and precise structures. Verify whether the supplier has successful case studies in relevant industries and essential certifications (e.g., IATF 16949, ISO 13485).

4. Quality Control System

Quality is the lifeline. Beyond basic ISO9001 certification, also investigate whether they have a complete Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC) process. Check if key inspection equipment such as Coordinate Measuring Machines (CMM), vision measuring systems, and colorimeters are available.

5. Supply Chain and Cost Control

Stable raw material supply and a transparent injection molding pricing system are crucial. Excellent suppliers have stable partnerships with major material suppliers like DuPont and BASF, and can recommend the most cost-effective material solutions based on your needs, avoiding hidden markups.

Overview and Feature Analysis of China's 10 Leading Injection Molding Companies in 2026

The following companies are selected based on industry reputation, technical strength, and comprehensive service capabilities. They are listed in no particular order and each has its own distinctive features.

| Company Name | Areas of Expertise / Specialization | Key Certifications & Scale |

|---|---|---|

| 1. Wsrcnc | High-precision CNC machining, metal stamping, injection molding. Deeply serves high-tech industries such as medical devices, defense and military, aerospace, artificial intelligence, and new energy. | Founded in 2014, focuses on process design and manufacturing of highly complex, high-precision products, possessing cross-technological integration capabilities. |

| 2. RapidDirect | Integrated full-process services including CNC machining, injection molding & tooling, sheet metal fabrication, die casting, 3D printing, etc. Services range from prototyping to mass production. | Certifications include ISO 9001, ISO 13485, IATF 16949. Combines own factory with 80+ partners, 700+ pieces of equipment, area > 25,000 m². |

| 3. TK Mold Ltd. | Mold design, high-cavity molds, multi-component molds, automated injection molding production. Serves automotive, EV, medical, and aerospace industries. | Certifications include ISO 9001, ISO 13485, ISO 14001. Total working area reaches 200,000 m², high level of automation. |

| 4. Guangdong Yizumi (Yizumi) | Electric/hybrid injection molding machines, robotic automation, turnkey intelligent manufacturing solutions. Specializes in plastic and rubber molding equipment. | ISO 9001, CE certification. Listed company, area approx. 600,000 m², over 3,000 employees. |

| 5. FOW Mold | Large industrial molds (precision ~0.005mm), insert/overmolding. Focuses on automotive, home appliances, etc. | ISO 9001, ISO 14001. Established in 1978, delivers 900+ sets of molds annually, with a long history. |

| 6. JMT Mould | Automotive interior/exterior trim molds, toy and home appliance molds. Provides mold design, simulation, prototyping, and finished product production. | IATF 16949, ISO 9001. Area 23,000 m², equipped with advanced machinery like five-axis machining centers. |

| 7. Packson Mold | Two-color mold manufacturing, cleanroom injection molding (Class 8), LSR. Focuses on medical, automotive, and electronics industries. | ISO 9001, ISO 13485, IATF 16949. Equipment range 60-800T, annual capacity 300+ sets of molds. |

| 8. Djmolding | Rapid prototype molds, LSR/overmolding/multi-color molding, mass production. Daily output approx. 1.8 tons. | ISO 9001, ISO/TS 16949. 40+ machines (40-800T), area approx. 15,000 m². |

| 9. Qmolding | 2K/LSR/overmolding, DFM, mold flow analysis. Serves packaging, electronics, medical, and aviation industries. | ISO 9001, ISO 14001. Founded in 2009, 600+ employees. |

| 10. ACO Mold | Mold testing and sampling, full-size plastic molding (max. ~4500 grams). Serves medical, electronics, lighting, etc. | ISO 9001. Annual output 300+ sets of molds, manufacturing capacity up to 15 tons. |

1wsrcnc

Wsrcnc Precision Machinery Co., Ltd. is a leading high-tech manufacturer focusing on high-precision CNC machining and metal stamping established in Shenzhen, China in 2014.

The company has an independent plant area of nearly 10,000 square meters, 130 employees, and more than 100 advanced processing equipment, such as CNC machining centers, high-precision CNC engraving machines, CNC lathes, turning and milling compound lathes, core machines, stamping equipment, etc., and has as many as dozens of testing instruments and experimental equipment such as three-coordinate measuring instruments, surface roughness testers, Rockwell hardness testers, salt spray machines, colorimeter, film thickness gauge, etc.

The company’s parts Geometric Tolerance accuracy can reach ±0.01mm, and the outer diameter tolerance accuracy can reach ±0.005mm. The processing and manufacturing of precision parts can bedelivered in 2-7 days at the fastest.

Our main processing technologies include CNC machining, turning, milling, drilling, grinding, stamping, casting, forging, polishing, rolling, welding, EDM, etc. Combining its own strong CNC turning and milling all-round processing capabilities, while integrating various first-class supply chain resources related to the industry, it can provide customers with a comprehensive one-stop services.

2. RapidDirect

RapidDirect is a China-based manufacturer founded in 2009 by Leon Huang and Team, with a mission of bridging the gap between design and manufacturing to provide comprehensive solutions to clients and companies worldwide.

Throughout its 16 years of operation, it has continuously developed its capabilities in the in-house factory and has over 80 active, vetted partners to bring designs to life more easily and quickly. You can enjoy AI-assisted instant quotes with DFM feedback before starting the project.

RapidDirect provides high-quality on-demand manufacturing services, including CNC machining, injection molding & mold-making, sheet metal fabrication, die-casting, 3D printing, wire EDM, extrusion, and surface finishing. Consequently, it is flexible in terms of production volumes and offers a range of solutions, from rapid prototyping to mass production.

Industry Served: Automotive, aerospace, medical, renewable energy, electronics & electrical, robotics, food-processing, industrial machinery, etc.

Client Types: Global industrial companies, startups & small businesses, value-added resellers, R&D institutions, procurement agencies, and individual personnel.

3. JMT Automotive Mould Co., Ltd

JMT was established in 2005 to provide comprehensive mold manufacturing services with minimal client input, particularly for the automotive industry. It not only focuses on manufacturing, but also helps in mold design, simulations, performance analysis, and conceptual prototyping. Consequently, they also produce finished & assembled plastic items according to the client’s needs.

This injection mold manufacturer was initially making molds for the domestic market, but later expanded its services to global businesses. Meanwhile, the total workshop area is 23,000 m² and has advanced automated facilities. You can leverage their 5-axis machining centres, double-headed precision EDMs, and other cutting-edge technologies for your project.

4. FOW Mold

FOW is one of the oldest plastic injection mold manufacturers China, working in the industry since 1978. Over the years, the company has adapted to the new trends and innovations in its production line. It has capabilities of insert molding, overmolding, and other types of injection molding technologies.

According to the latest data, FOW is delivering 900+ custom molds/year in the European and US markets, along with several ready-to-use molding parts & products.

The core services include end-to-end mold tooling and full-scale molding of parts for diverse sectors, such as automotive, household appliances, pet products, furniture, and bucket-like items.

5. Qmolding

It is another cost-effective and export-oriented manufacturer of plastic molding parts and custom molds, working since 2009. Qmolding also handles pre-production tasks, such as DFM optimization, mold flow analysis, and conceptual & functional prototyping. Consequently, the core industries that Qmolding serves are packaging, electronics, medical, and aviation.

This China-based 2 K injection molding manufacturer operates an in-house facility equipped with CNC machines, EDM/wire-cut machines, LSR molding machines, and surface treatment systems. Furthermore, over 600 staff members work in that facility.

6. Guangdong Yizumi Precision Machinery

Guangdong Yizumi stands as one of the leading injection molding machine companies in China, founded in the early 2000s. It offers a wide range of standards and custom equipment for plastic molding, rubber molding, casting, and forging, featuring integration of automation and robotics. Subsequently, the company also helps with installation and some after-sales maintenance.

Their reliability and machine quality are also recognized through various awards, including strength enterprises of the plastics machinery, small & medium-sized enterprise of the most Developmental Potential, and an advanced enterprise of scientific and technological innovation in 2020.

Guangdong Yizumi is the first Chinese molding manufacturer to be listed on the Shenzhen Stock Exchange. Furthermore, the total area of the workspace is approximately 600,000 m² worldwide, employing a workforce of over 3,000 staff.

7. Packson Mold

Packson Mold was established in 2006 as a mold-making company, but later it expanded to a one-stop contract manufacturer of plastic parts, from designing and flow simulation to production of finished parts.

It mainly serves the medical, automotive, electrical, and agricultural industries with intricate molds, mold components, and custom molding products. Additionally, it also produces CNC metal machining parts.

Packson Mold has several pieces of equipment (60T-800T) in its workshop, which spans over 1000 m², capable of delivering more than 300 sets/year. Consequently, over 150 experienced staff members are working in the company.

Try RapidDirect Now!

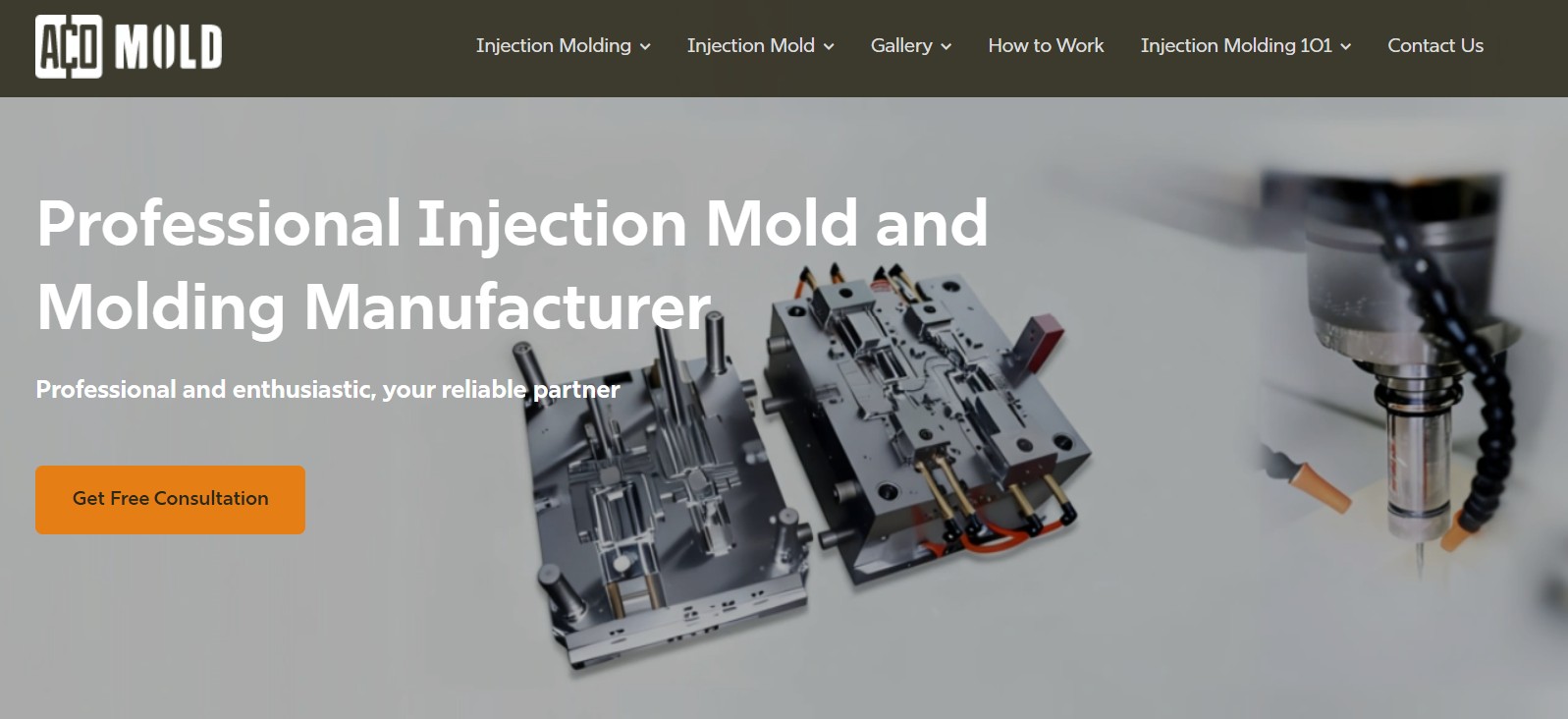

8. ACO Mold

ACO mold is another plastic molding and injection mold manufacturer in China, founded in 2000 with a small CNC machine shop. However, it later expanded its capabilities to become a one-stop molding service for businesses.

The company’s goal is to provide cost-effective mold solutions for diverse applications in the fast-paced market, including part design, prototyping, production, assembly, and even reverse engineering for specific items. ACO mold serves the medical, electronics, fitting, lighting, and agricultural industries.

ACO has a machining and molding facility that handles over 30 plastics and produces more than 300 sets of molds annually. Consequently, it has a manufacturing capability of up to 15 tons.

9. Djmolding

Djmolding is another China family tool injection molding manufacturer that also produces low-volume and full-scale molding parts. This company was founded in 2010 and has been collaborating with international customers for custom projects.

The core services of Djmolding are mold design & manufacturing, prototyping, mold repair, plastic injection molding, LSR, overmolding, multi-color molding, silk printing, pad printing, and CNC machining of metal parts.

Djmolding has 40+ injection molding quipmements, ranging from 40-800 tons. They can run 24/7 to produce plastic components & products weighing ~1.8 tonnes per day. So, it is suitable for large batches, 50,000+ identical pieces. Subsequently, the workshop floor of Djmolding covers ~15,000 m² of area.

10. TK Mold Ltd

TK mold is one of the oldest plastic injection molding companies in China, founded in the early 1980s. Although it was established in Hong Kong, TK Mold now has its headquarters in Shenzhen and a strong presence in Europe & US.

The company has in-house design, mold production, injection molding, and secondary processing solutions for industries like automotive, EVs, defense, aerospace, medical, electronics, and consumer goods.

TK mold has automated production lines with mechanical arms to enhance efficiency and speed. Meanwhile, its combined workspace of TK mold company in Shenzhen and Germany is 200,000 m².

Why is Wsrcnc the Preferred Choice for Your High-Tech Manufacturing Projects?

After evaluating numerous excellent suppliers, why does Wsrcnc stand out in the field of precision manufacturing and become a trusted partner for industry leaders in sectors such as medical devices, aerospace, and artificial intelligence? The reason lies in our ability to address the core pain points in high-end manufacturing

Choosing Wsrcnc means selecting a strategic partner grounded in cutting-edge manufacturing technology and oriented toward solving complex problems. We are committed to transforming your innovative ideas into stable, reliable, high-performance products.

Get Your Customized Manufacturing Solution Now

Facing complex project requirements and unsure which combination of processes is optimal? Share your design drawings or product concepts with us. Wsrcnc’s engineering team will provide you with a comprehensive plan that integrates process analysis, technical routes, and preliminary cost evaluation.

[Click here to contact the Wsrcnc expert team for a free technical consultation]