Sheet Metal Welding: 5 Common Methods and Selection Guide

In the metal manufacturing industry, sheet metal welding is a crucial process for achieving structural connections and ensuring product strength and functionality. However, sheet metal is typically thin (generally referring to metal sheets less than 6mm thick) and extremely sensitive to heat input. Choosing the wrong welding method can easily lead to problems such as deformation, burn-through, insufficient strength, or poor appearance.

This article will delve into five commonly used welding methods best suited for sheet metal and provide a clear decision-making process to help engineers, designers, and purchasing personnel make the most cost-effective choices based on project requirements.

Core Challenges of Sheet Metal Welding

Before discussing methods, it's essential to understand the unique requirements of sheet metal welding:

Controlling Heat Input:Excessive heat concentration can cause sheet metal warping and burn-through.

Aesthetic Appeal:Many sheet metal parts are aesthetic components, requiring smooth and even weld seams.

Material Diversity:It must be adaptable to various materials such as low-carbon steel, stainless steel, and aluminum.

Efficiency and Cost: Balancing welding speed, equipment investment, and post-processing costs.

Detailed Explanation of Five Commonly Used Sheet Metal Welding Methods

1. Gas Shielded Tungsten Inert Gas Welding (GTAW)

TIG Welding Principle: Welding is performed using an electric arc generated between a non-consumable tungsten electrode and the workpiece. An inert gas (such as argon) is required to protect the molten pool.

Applicable Thickness: Extremely fine, suitable for ultra-thin sheets (above 0.5mm) to medium-thickness sheets.

Advantages: Precise and controllable heat input, minimal deformation. Extremely high weld quality, clean and aesthetically pleasing, no slag removal required. Can weld almost all metals, especially stainless steel and aluminum.

Disadvantages: Requires high operator skill; relatively slow welding speed.

Best Applications: Products with high appearance requirements (such as chassis, decorative parts), precision parts, piping, aerospace components.

2. Gas Shielded Metal Inert Gas Welding (GMAW)

MIG/MAG Welding Principle: Welding is performed using a continuously fed solid or flux-cored welding wire as the electrode and filler material under a shielding gas.

Applicable Thickness: Highly versatile, suitable for rapid welding of medium thicknesses (above 1mm).

Advantages:Fast welding speed, high production efficiency. Relatively simple operation, easy to automate (robotic welding). Wide range of applicable materials (steel, aluminum, etc.).

Disadvantages:More complex equipment, certain requirements for welding position, shielding gas has costs.

Optimal Applications:Medium to thick plate structural parts, mass production, long straight seam welding, automated production lines.

3. Resistance Spot Welding

Resistance Spot Welding Principle:Utilizes the resistance heat generated when current passes through overlapping metal plates, forming a localized weld nugget under pressure. Primarily used for thin plate overlaps (typically total thickness ≤ 3mm).

Advantages: Extremely fast, suitable for large-scale production. No filler material or shielding gas required, low cost.

Small deformation, easy to automate.

Disadvantages:The connection is "point-like," resulting in poor sealing; joint strength depends on the number and layout of weld points.

Optimal Applications:Large-volume overlap parts such as automotive bodies, cabinet enclosures, and appliance casings (e.g., washing machine drums)

4. Laser Welding

Laser welding principle: Utilizes a high-energy-density laser beam as a heat source for precision melting and welding. Suitable for ultra-thin to medium-thickness precision welding.

Advantages: Highly concentrated energy, minimal heat-affected zone, and minimal deformation. Extremely fast welding speed and large depth ratio. Capable of micro-welding, easy for robot integration and programming.

Disadvantages: Expensive equipment investment; extremely high requirements for workpiece assembly clearance (tight fit is necessary).

Best applications: Consumer electronics (mobile phones, laptops), medical equipment, precision sensors, battery sealing welding.

5. Plasma Arc Welding

Plasma arc welding principle: The electric arc is compressed by the plasma welding torch, forming a more concentrated and higher-temperature plasma arc. Applicable thickness: Between TIG and laser welding, suitable for medium-precision close-fitting welding.

Advantages: More concentrated energy than TIG welding, greater penetration depth, and faster speed. More stable arc, enabling single-sided welding with double-sided forming. Can weld thicker plates in keyhole mode.

Disadvantages: Equipment cost and complexity are higher than TIG welding.

Optimal applications: Industries with high requirements for welding quality and speed, such as automotive exhaust pipes, pressure vessels, and longitudinal seams in pipelines.

How to choose a sheet metal welding method?

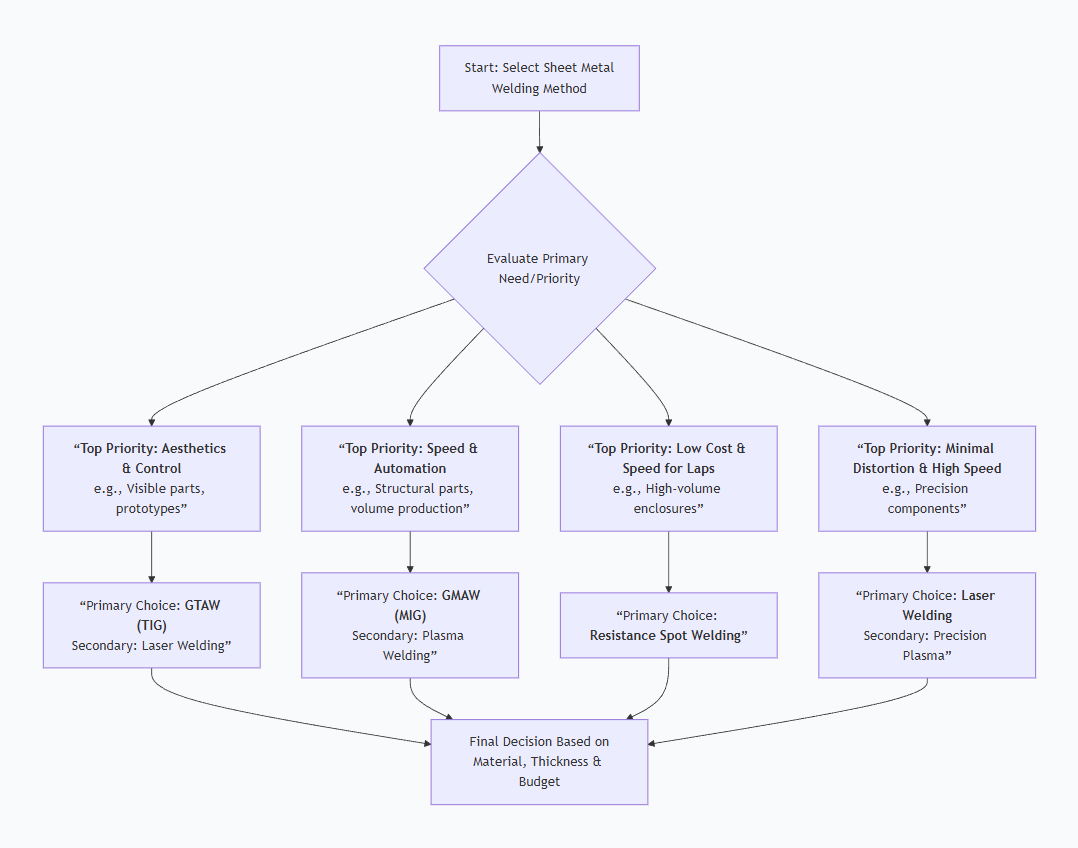

To make a clear choice, please follow this decision-making process:

Detailed Sheet Metal Welding Decision-Making Steps

Identify Primary Objectives: Based on the diagram above, determine the core driving force of the project (quality, efficiency, cost, or precision).

Evaluate Materials and Thickness:

Aluminum and Aluminum Alloys: TIG welding or pulsed MIG welding are preferred.

Stainless Steel: TIG welding (aesthetics), MIG welding (efficiency), and laser welding (precision) are all acceptable.

Low Carbon Steel: MIG welding is the most commonly used; spot welding is suitable for lap joints.

Thickness < 1mm: Prioritize TIG, laser, or micro-plasma welding.

Thickness 1-3mm: MIG, TIG, and plasma are all good choices.

Thickness > 3mm: Beveling may be required; MIG or plasma welding is more efficient.

Consider Production Volume and Budget

Prototype/Small Batch: TIG welding is flexible and has relatively low equipment investment.

High-volume/Automation: Prioritize MIG welding robots, laser welding, or automated spot welding lines. Although the initial investment is high, the cost per unit is low.

Consider Appearance and Post-processing Requirements

If the weld is to be directly painted or used as an aesthetic finish, choose a method that produces an attractive weld (TIG, laser).