Mold manufacturing is the core precision machining process that designs, processes and fabricates customized mold tools for mass production of industrial parts and products—whether it’s plastic injection parts, metal stamping parts, die-casting components or rubber products, mold manufacturing is the "mother of industry" that determines the precision, consistency and production efficiency of finished products. As a professional precision manufacturing enterprise with rich experience in mold processing and CNC machining, wsrcnc masters the full-process technology of mold design, development, processing and trial production, serving automotive, electronics, medical, consumer goods and other industries with high-precision mold solutions. This article will comprehensively explain the core connotation of mold manufacturing, sort out its complete development process, key processing technologies and standardized production flow, and interpret the core links that determine mold quality and service life.

What is mold manufacturing?

Mold manufacturing refers to the process of designing, machining, and manufacturing molds (also known as tools or dies) for the mass production of parts of specific shapes and sizes. A mold itself is a high-precision tool capable of shaping material into the desired form under pressure.

A Detailed Explanation of the Mold Manufacturing Process

The Principles of Mold Manufacturing

Understanding the principles of mold manufacturing reveals the intricate production processes behind countless products encountered daily.

The core of mold making lies in creating a negative space or cavity that perfectly matches the shape of the desired object. This cavity then serves as a template for producing multiple copies of that object, whether in plastic, metal, or any other material. The entire process is meticulously planned and executed to ensure the final product achieves the highest quality and precision.

The main steps of mold manufacturing include:

Design and Conceptualization

The process begins with a detailed design phase where engineers and designers collaborate to create a 3D model of the part to be produced. This model acts as the blueprint for the mold, incorporating all necessary features such as cavities, cores, and ejection systems, while also accounting for thermal and mechanical stresses the mold will endure.Material Selection

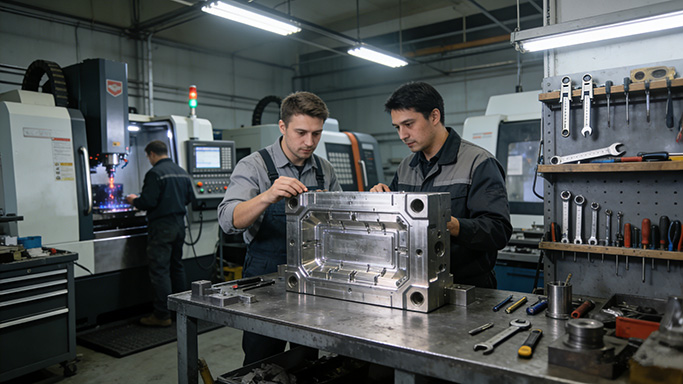

Choosing the right mold material is critical. Factors like the mold's intended use, the material of the final product, and production volume significantly influence this decision. Common materials include: steel for high-volume production molds, aluminum for rapid heat dissipation, and silicone or rubber for flexible mold components.Machining and Fabrication

Once the design is finalized and materials are selected, the physical creation of the mold begins. The mold can be manufactured using various techniques such as Computer Numerical Control (CNC) machining, Electrical Discharge Machining (EDM), and 3D printing. This step requires extreme precision to ensure the mold accurately reflects the design specifications.Surface Finishing and Polishing

After machining, the mold undergoes surface finishing to enhance its quality and functionality. Polishing is crucial for achieving the desired surface finish on the final product, especially for injection molds where part smoothness is paramount.Assembly and Testing

The various components of the mold are assembled into a complete unit. Assembly must be performed with great accuracy to ensure the mold functions correctly and safely. The assembled mold is then tested to verify it fills properly, cools appropriately, and ejects parts smoothly.Trial Run and Adjustment

Before full-scale production, a trial run is conducted to identify any issues with the mold or the molding process. This phase allows for fine-tuning the mold, adjusting parameters like temperature, pressure, and cycle time as needed to ensure optimal performance.Final Inspection and Approval

The final step involves a comprehensive inspection of the mold and trial-produced parts to ensure they meet all specifications and quality standards. Once it passes the final inspection, the mold is approved for mass production.

The seamless integration of these processes enhances the efficiency of producing high-quality molds capable of replicating almost any object with precision and consistency. The versatility and adaptability of mold manufacturing underscore its indispensable role in today's manufacturing landscape, serving a wide range of industries from automotive and healthcare to consumer goods.

What materials are supported by mold making?

Mold making supports an extremely wide range of materials, almost covering all materials that can be molded by flow, filling, pressurization, or heating. Based on different molding processes, they can be mainly divided into the following categories:

1. Materials for Different Molding Processes

Plastics Molding

Thermoplastics: The most common category, including PP (Polypropylene), PE (Polyethylene), ABS, PC (Polycarbonate), Nylon (PA), POM (Acetal), PMMA (Acrylic), etc. Used in injection molding to produce the vast majority of plastic products.

Thermosetting Plastics: Such as epoxy resin, phenolic resin, unsaturated polyester, etc. Processed via compression molding or transfer molding into electrical components, tableware, etc.

Elastomers: Such as silicone, rubber (NR, SBR, EPDM, etc.). Produced via rubber injection molding or die casting to make seals, gaskets, shoe soles, etc.

Metal Forming

Die Casting Molds: For metals with relatively low melting points, such as zinc alloys, magnesium alloys, aluminum alloys (most common). Used to produce automotive parts, 3C product housings, etc.

Forging Dies: For plastically deforming metals like steel, titanium alloys, aluminum alloys at high temperatures to produce high-strength structural components (e.g., crankshafts, connecting rods).

Stamping Dies: For shearing, bending, and drawing metal sheets like steel plate, stainless steel, copper sheet, aluminum sheet to produce car bodies, appliance housings, structural parts, etc.

Powder Metallurgy Molds: For compacting metal powders (e.g., iron-based, copper-based) into shape followed by sintering to produce complex small parts like gears, oil-impregnated bearings.

Molds for Other Materials

Glass Molds: For blowing or pressing glass to produce bottles, vessels, optical components.

Ceramic Molds: For dry pressing, slip casting, or isostatic pressing of ceramic powders to produce tableware, electronic components, sanitary ware.

Composite Material Molds: For laying up and curing carbon fiber prepregs, glass fiber reinforced plastics to produce aerospace, high-end sports equipment components.

Food/Confectionery Molds: For shaping chocolate, candy, baked goods.

Sand Casting Molds / Wax Patterns: Although the molds themselves (sand or wax) are disposable, they are intermediate tools for producing large metal castings (e.g., engine blocks) from materials like cast iron and copper alloys.

2. Material Selection for the Molds Themselves

The material for the mold itself depends on the product material, production volume, precision, and cost.

Metal Molds (Mainstream, for Mass Production)

Tool Steel: Most commonly used, e.g., P20 (pre-hardened steel), H13 (hot work steel), S136 (stainless mold steel). Offers wear resistance, high-temperature resistance, and long life.

Aluminum Alloy: e.g., 7075, 6061. Used for rapid prototyping, low-volume production, or molds requiring high thermal conductivity (injection/die casting). Fast to machine but shorter lifespan.

Beryllium Copper Alloy: Used for mold areas requiring extremely fast heat dissipation.

Cast Iron: Used for large, low-cost molds or mold bases.

Non-Metal Molds (for Prototyping, Low Volume, or Special Processes)

Silicone/Rubber Molds: Often used for vacuum casting or low-pressure infusion to replicate small batches of resin (e.g., polyurethane PU), plaster, wax prototypes.

Epoxy Resin Molds: Used for hand lay-up or vacuum infusion processes with composite materials (e.g., carbon fiber) to create product prototypes or low-volume parts.

3D Printed Molds (Rapid Tooling): Using materials like photosensitive resin or metal powder to directly 3D print mold cavities. Used for very low-volume trial production or highly complex internal channels.

Summary

In simple terms, molds are the "mother machines" of modern manufacturing, capable of supporting almost any material:

End-Product Materials: From everyday plastics and metals to specialized glass, ceramics, composites, and food.

Mold Materials Themselves: From steel and aluminum for mass production to silicone and resin for prototype development.

The core principle is: Using a precisely manufactured cavity to impart a specific shape, size, and surface finish to a material, thereby enabling efficient, consistent, and scalable production of products. Advances in mold technology also directly drive the application of new materials and expand the possibilities of product design.

How much does mold making typically cost?

Inexpensive: Silicone casting molds, 3D printed molds, used for making a few to dozens of samples, costing several hundred to several thousand yuan.

Most common: Injection molds for ordinary plastic products, used to produce thousands to hundreds of thousands of products, generally costing tens of thousands to two hundred thousand yuan.

Expensive: Large, complex, high-precision, long-life molds (such as automotive parts, precision gears), costing hundreds of thousands or even millions of yuan.

A quick estimate requires:

3D model of the product (most important).

Expected production volume (determines mold material and lifespan).

Product material (plastic, metal, etc.).

Surface requirements (smooth finish, textured finish, etc.).

The final quote will be provided by the mold factory after evaluation based on detailed drawings.