Advanced CNC Machining Solutions in the Aerospace Industry

In the aerospace field, where safety, reliability, and performance are paramount, every component is crucial to life and mission success. Aerospace CNC machining is the cornerstone technology supporting this high-end manufacturing industry, representing the pinnacle of modern precision manufacturing.

What is Aerospace CNC Machining?

Aerospace CNC machining is a manufacturing process that utilizes a computer numerical control (CNC) system to perform high-precision, high-efficiency cutting and shaping of high-strength metals, alloys, and special materials. It surpasses the standards of ordinary CNC machining, imposing near-stringent requirements on tolerances, surface integrity, and traceability, aiming to manufacture critical aircraft components that can operate stably under extreme environments (high temperature, high pressure, high load).

CNC Machining Process in the Aerospace Industry

The operation of aerospace CNC machining is a closed-loop process integrating digital design and precision manufacturing:

Digital Design: Three-dimensional design of parts is performed based on CAD models, and CAM software is used to plan toolpaths, cutting parameters, and generate G-code.

Precision Programming and Simulation: Programmers write detailed machining programs and use virtual simulation technology to predict and avoid collisions and overcuts during machining.

High-Rigidity Machine Tool Machining: The program is imported into a highly stable and rigid multi-axis CNC machine tool for cutting rigorously certified blanks.

Full-Process Quality Monitoring: During and after machining, precision equipment such as coordinate measuring machines and in-machine probes are used to monitor part dimensions in real time, ensuring 100% conformity to design drawings.

Core Advantages of CNC Technology in the Aerospace Field

* Extreme Precision and Consistency: Tolerances of ±0.025 mm or even tighter can be easily achieved, ensuring high consistency and interchangeability of millions of parts.

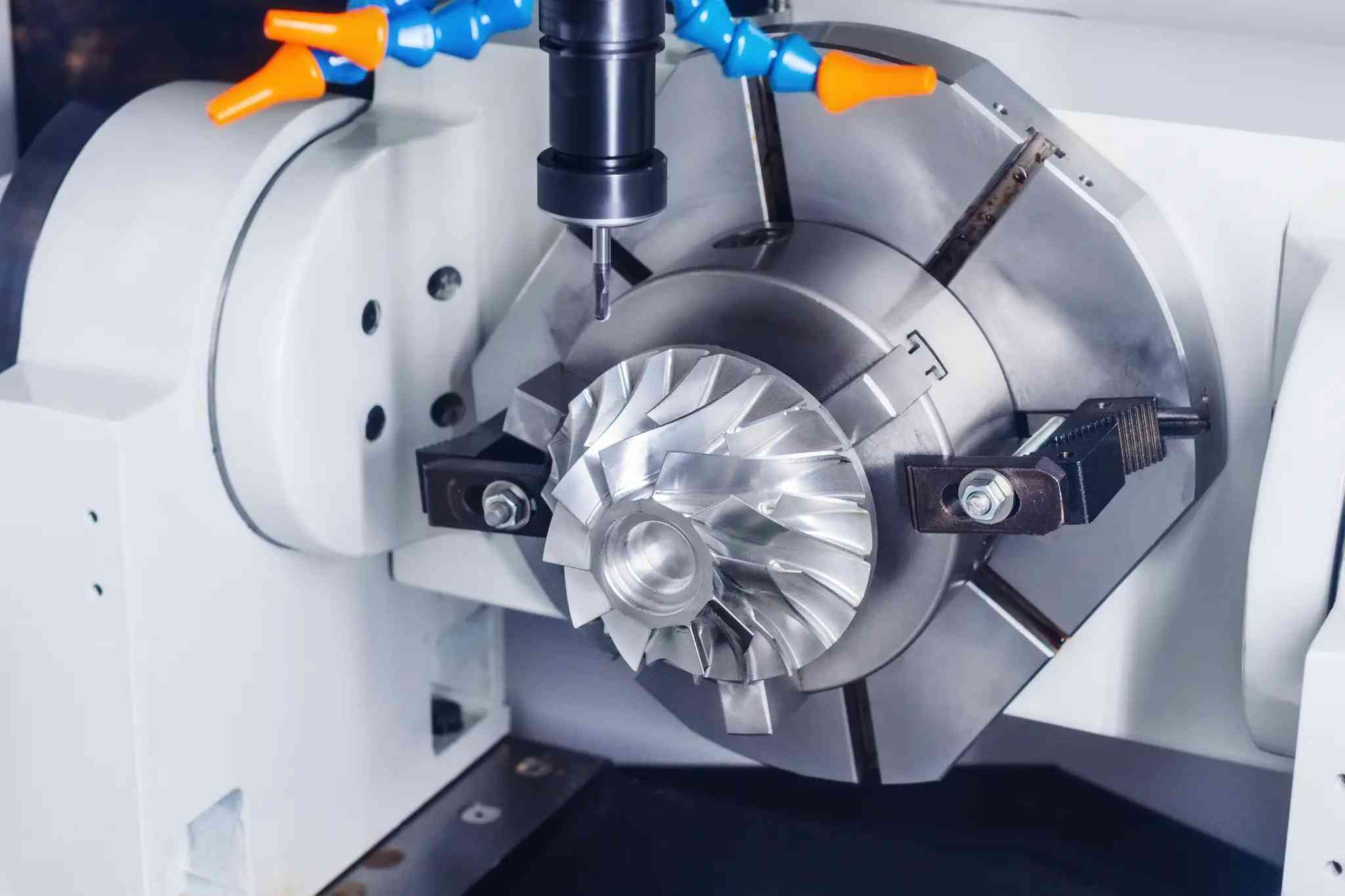

Complex Geometry Capability: Five-axis simultaneous machining technology can complete the forming of parts with complex curved surfaces, such as impellers and engine casings, in one operation, which is impossible with traditional methods.

Superior Material Utilization: By using subtractive manufacturing of high-strength and valuable materials, material waste is significantly reduced, lowering production costs.

Unparalleled Traceability: Processing data for every step and every part can be recorded and tracked, providing a complete data chain for quality control and accident analysis.

Key Types of Aerospace CNC Machine Tools

Five-Axis Machining Center: Core equipment, capable of simultaneously controlling three linear axes and two rotary axes, used for machining complex aerospace structural components.

Mill-Turn Center: Integrates turning, milling, drilling, and tapping functions, completing all processes in a single setup, greatly improving accuracy and efficiency.

High-Speed Milling Center: Designed for efficient machining of lightweight materials such as aluminum alloys, suitable for components such as avionics equipment housings.

Fiber Winding Machine: Used for manufacturing composite material fuselages, rocket engine casings, etc.

Application Scenarios of CNC Machining

The application of aerospace CNC machining permeates every core system of aircraft, from passenger planes soaring in the sky to spacecraft exploring the universe. Its application scenarios can be summarized into the following four major areas:

1. Aircraft Components

Structural Components: Fuselage frame, wing spars, ribs, landing gear components.

Engine Components: Turbine blades, compressor bladed disks, engine casing, fuel nozzles.

Interior and Systems: Seat frame, control stick, hydraulic valve block.

2. Spacecraft and Satellite Components

Propulsion Systems: Satellite thruster brackets, rocket engine injectors.

Structural Components: Satellite trusses, camera lens barrels, docking mechanism parts.

Payload: Precision reflector brackets, sensor housings.

3. Avionics and Instrumentation

Housing and Base: Radar housing, flight computer housing, inertial navigation system base, requiring extremely high electromagnetic shielding and dimensional stability.

4. Ground Support Equipment

Inspection Fixtures: Specialized jigs and clamps used for locating and inspecting aircraft components.

Simulation Equipment Parts: Precision moving parts of flight simulators.

Commonly Used Aerospace CNC Machining Materials

Next, we will delve into the key materials commonly used in aerospace CNC machining. The selection of these materials directly determines the performance, safety, and service life of the aircraft. They all possess characteristics such as high strength, lightweight, and resistance to extreme environments.

Aluminum alloys: such as 7075 and 6061, possess excellent strength-to-weight ratio and are widely used in aircraft structural components.

Titanium alloys: such as Ti-6Al-4V, offer high strength, corrosion resistance, and high-temperature resistance, making them the preferred choice for engines and critical structural components.

Nickel-based superalloys: such as Inconel 718, exhibit excellent thermal fatigue resistance and are used in engine hot-end components.

Stainless steel: such as 15-5PH, is used in high-strength hydraulic systems and landing gear components.

High-performance plastics: such as PEEK and ULTEM, are used in insulation components, gaskets, and interior trim components.

Composite materials: such as carbon fiber reinforced polymers, are used to manufacture lightweight, high-strength modern fuselages and wings.

Common Surface Finishes for Aerospace Parts

The common surface finishes for aerospace parts are a crucial topic. It goes far beyond mere aesthetics, directly impacting the performance, reliability, lifespan, and safety of the parts.

Mirror polishing: Reduces surface friction resistance, suitable for engine fuel components and hydraulic systems, and prevents cavitation corrosion. Anodizing: Primarily used on aluminum alloys, providing a corrosion-resistant, wear-resistant, hard surface layer and allowing for different color markings.

Chemical Conversion Coating: Such as chromate conversion coatings, providing basic corrosion resistance and good paint adhesion for aluminum and magnesium alloys.

Sandblasting: Produces a uniform matte surface, used to eliminate tool marks, improve coating adhesion, or achieve a consistent visual effect.

Electroless Nickel Plating: Provides a uniform, high-hardness, corrosion-resistant coating, especially suitable for parts with complex geometries.

Ceramic Coating: Offers extremely high heat resistance and insulation properties, widely used in engine turbine blades and combustion chambers.

Laser Engraving: Used to imprint permanent part numbers, serial numbers, and batch numbers, enabling traceability throughout the entire lifecycle.

Summary: Why Choose Wsrcnc as Your Aerospace CNC Machining Partner?

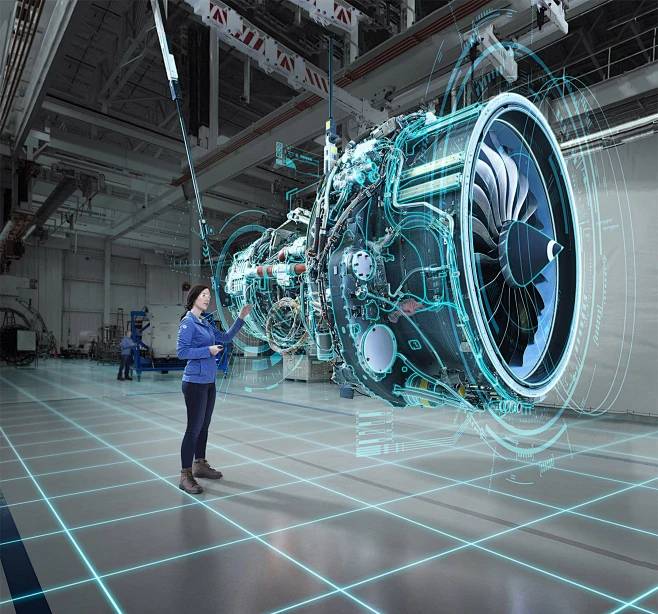

Looking at the entire landscape of aerospace manufacturing, from airframes to engine cores, from satellite structures to avionics systems, the cornerstone of their superior performance relies on the perfect fusion of advanced CNC machining technology and cutting-edge special materials. The pursuit of ultra-high precision, extreme lightweighting, and absolute reliability permeates the entire lifecycle of every component.

In this high-barrier, high-standard field, WSRCNC, as a professional CNC machining factory specializing in aerospace components with many years of industry experience, consistently stays at the forefront of technology. We deeply understand the characteristics of difficult-to-machine materials, from aluminum alloys and titanium alloys to nickel-based superalloys, and rely on advanced equipment such as five-axis machining centers and mill-turning composite machines to provide customers with comprehensive solutions ranging from complex structural parts and engine core components to precision avionics housings.

We deeply understand that every component is crucial to safety and mission. Therefore, we not only pursue micron-level tolerance control but also have built a comprehensive quality assurance system. We offer professional surface treatment processes, including anodizing, electroless nickel plating, sandblasting, and laser engraving, ensuring that parts fully meet international aerospace quality standards such as AS9100 in terms of corrosion resistance, wear resistance, and full lifecycle traceability.

Choosing WSRCNC means choosing not just a supplier, but a trustworthy engineering and manufacturing partner. Leveraging our expertise and technical strength in aerospace CNC machining, we help your projects achieve the optimal balance between performance, cost, and delivery time, jointly advancing humanity's journey to explore the boundaries of the universe.