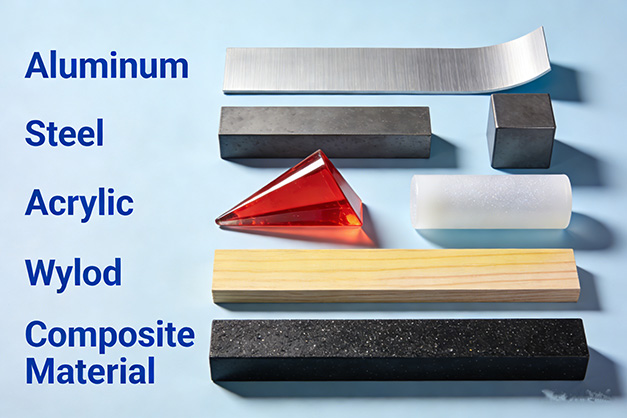

What Materials Can CNC Machines Process?

CNC machine tools are highly flexible manufacturing systems capable of processing an extremely wide range of materials, from common metals to various special materials. Their specific capabilities depend on the machine type, power, rigidity, and the cutting tools used.

Here are common processable materials detailed by category:

1. Metal Materials (The Most Extensive Processing Area)

This is the most common domain for CNC machining, especially CNC milling machines and lathes.

Steels

Carbon Steels: e.g., A36, 1018, 1045. Easy to machine, used for structural parts, shafts.

Alloy Steels: e.g., 4140, 4340. High strength, used for molds, gears, aerospace components.

Tool Steels: e.g., D2, H13, P20. High hardness and wear resistance, specifically for making injection molds, stamping dies, die-casting molds.

Stainless Steels: e.g., 303 (free-machining), 304/316 (austenitic, corrosion-resistant), 440C (martensitic, high hardness). Machining difficulty and tool wear increase accordingly.

Aluminum Alloys

One of the easiest metals to machine, lightweight with good thermal conductivity. e.g., 6061, 7075, 5083. Widely used in aerospace, automotive, consumer electronics, and prototyping.

Titanium Alloys

e.g., TC4 (Ti-6Al-4V). High strength-to-weight ratio, corrosion-resistant, but challenging to machine (poor thermal conductivity, prone to work hardening). Requires specialized tools, low speeds, and high-rigidity machines. Primarily used in aerospace and medical implants.

Copper & Copper Alloys

Pure Copper: Excellent thermal/electrical conductivity, but soft and gummy.

Brass: e.g., C36000, known as a free-machining material, commonly used for valves, hardware, decorations.

Bronze: Good wear resistance, used for bearings, bushings.

Magnesium Alloys

Lighter than aluminum, easy to machine, but flammable. Requires strict safety measures (dust and fire prevention). Used in weight-sensitive aerospace and racing components.

Nickel-based Superalloys

e.g., Inconel 718, Hastelloy. Extremely difficult to machine. Heat and corrosion-resistant with very high strength, generating significant heat and cutting forces during machining. Used for jet engine parts, turbine disks, and other high-heat components.

Cast Iron

e.g., Gray iron, Ductile iron. Wear-resistant with good damping properties, often used for machine bases, engine blocks, brake rotors.

2. Plastics & Composites

CNC can precisely machine various engineering plastics without thermal distortion issues.

General-Purpose Plastics: ABS, PP, PMMA (Acrylic), PVC.

Engineering Plastics: PC (Polycarbonate), POM (Acetal/Delrin), PA (Nylon), PEEK (high-performance, used in medical and aerospace).

Composites:

Fiberglass Reinforced Plastics (FRP): Light and strong, but causes rapid tool wear.

Carbon Fiber Reinforced Polymers (CFRP): Extremely high strength-to-weight ratio, requires specialized diamond-coated tools, and careful control to prevent delamination and fraying.

G10/FR4 Epoxy Glass Laminates: Excellent electrical insulation, used for circuit board substrates and insulating parts.

3. Wood & Wood-based Composites

CNC routers are widely used in woodworking.

Solid Wood: Hardwoods, softwoods.

Engineered Wood: Plywood, MDF (Medium-Density Fiberboard), Particleboard, OSB (Oriented Strand Board).

4. Other Non-Metallic Materials

Foams: EPS (Styrofoam), PU (Polyurethane foam), used for packaging, prototyping, sculptures, and mold patterns.

Stone: Marble, granite, engineered quartz, used for carving and decorative pieces (requires specialized CNC stone engraving machines).

Glass: Primarily for engraving and drilling, requiring specialized equipment and processes.

Composite Sheets: e.g., Aluminum composite panels, high-pressure laminates.

Key Influencing Factors & Considerations

Machine Capability:

Metal machining requires high-power, high-rigidity, high-precision CNC machines (like machining centers).

Wood, plastics, and foams can be processed with lower-power/rigidity CNC routers.

Wire EDM is specialized for precision contouring of conductive materials.

Tool Selection: Different materials require corresponding tool materials, coatings, and geometries.

HSS (High-Speed Steel): General purpose, low cost.

Carbide: Most commonly used, balances wear resistance and toughness.

Coated Tools: e.g., TiAlN coating is suitable for hard steels and superalloys.

Diamond Tools: For non-ferrous metals, composites, and graphite.

CBN (Cubic Boron Nitride): For hardened steels and cast irons.

Cutting Parameters: Speed, feed rate, and depth of cut must be precisely set based on material properties. For example, titanium requires low speed and high feed to avoid work hardening, while aluminum can use high speed and high feed.

Cooling & Lubrication:

Most metal machining requires cutting fluid or oil for cooling, lubrication, and chip removal.

Water-based coolants are strictly prohibited for magnesium alloys (to prevent hydrogen gas explosion).

Dry cutting or air blast is common for wood, plastics, and composites.

In summary, the range of materials processable by CNC machines is virtually limitless. The key lies in matching the appropriate machine, tools, cutting parameters, and process plan for the specific material. From everyday objects to cutting-edge aerospace components, CNC technology plays a central role in manufacturing.

4 Q&A on CNC Machining Materials

Q1: What is the easiest metal to machine with CNC, and why?

A1: Brass, specifically leaded brass like C36000, is often considered one of the easiest metals to machine. It's known as a "free-machining" material because the lead inclusions act as a lubricant, allowing for high cutting speeds, smooth surface finishes, excellent chip breakage, and minimal tool wear.

Q2: What makes titanium and superalloys like Inconel so difficult to machine?

A2: Their difficulty stems from a combination of properties: low thermal conductivity (heat concentrates at the cutting edge), high strength at elevated temperatures, a tendency to work-harden rapidly, and high chemical reactivity with tool materials. This leads to excessive tool wear, high cutting forces, and the need for specialized, conservative machining strategies.

Q3: Can I machine plastics on the same CNC machine used for metals?

A3: Yes, often you can, but it's not always optimal. A metal CNC machine is certainly capable. However, plastics require sharper tools, higher spindle speeds, and often different workholding (to avoid crushing). Dust/chip extraction is also crucial. For high-volume plastic machining, a CNC router with a high-speed spindle and dedicated vacuum table might be more efficient.

Q4: Why is tool selection so critical when switching materials?

A4: Different materials interact with cutting tools in unique ways. Using the wrong tool material or geometry can cause: premature tool failure (chipping, wear), poor surface finish, workpiece damage (melting, delamination), inefficient machining (slow speeds/feeds), and even safety hazards. The right tool optimizes cost, quality, and productivity.

Why Choose Wsrcnc for Your Machining Projects?

Selecting the right manufacturing partner is crucial for the success of your project. Here’s why Wsrcnc stands out as a premier choice for precision CNC machining:

Extensive Material Expertise & Inventory: We have deep, practical experience machining the full spectrum of materials—from common aluminums and steels to challenging titanium, Inconel, and advanced composites. Our in-house material knowledge ensures optimal process planning from the start.

Advanced Technology & Rigorous Quality Control: Our facility is equipped with state-of-the-art, high-precision CNC machining centers, lathes, and inspection equipment (like CMMs). We implement a strict quality management system throughout the entire process, from material certification to final inspection, guaranteeing parts that meet your most demanding specifications and drawings.

Engineering Support & DFM Feedback: We are more than just a machine shop. Our engineering team provides valuable Design for Manufacturability (DFM) feedback. We can suggest design tweaks that enhance functionality, reduce cost, or shorten lead times without compromising your intent, ensuring your design is optimized for production.

Reliability, Transparency & On-Time Delivery: We understand the importance of your supply chain. Wsrcnc is committed to transparent communication, providing regular project updates. We pride ourselves on meeting agreed-upon deadlines with consistent reliability, ensuring your projects move forward smoothly.

Customer-Centric Service & Competitive Value: We view our clients as long-term partners. Our focus is on building relationships by understanding your goals and providing responsive, professional service. We offer competitive pricing that reflects true value—combining high quality, expert service, and reliable delivery.

Partner with Wsrcnc to transform your designs into high-quality, precision-engineered components. Contact us today to discuss your project requirements and receive a detailed quote.