2025 CNC Machining Industry Outlook: Eight Key Technology Trends

With the deepening development of Industry 4.0, CNC (computer numerical control) machining technology is undergoing a revolutionary transformation. This article will provide a detailed analysis of the ten most noteworthy CNC machining trends in 2025, helping manufacturers plan ahead and maintain a competitive advantage.

AI-powered Adaptive CNC Machining Systems in 2025

By 2025, adaptive CNC systems equipped with AI algorithms will become a core competitive advantage in high-end manufacturing. By real-time monitoring of key parameters such as cutting force, vibration, and temperature, they will automatically optimize the machining process, significantly improving production efficiency and product consistency. Compared to traditional CNC machining, AI-powered control systems can dynamically adjust cutting parameters, reducing human intervention and avoiding precision deviations caused by operator errors.

Furthermore, predictive maintenance functions based on machine learning can accurately determine tool wear and automatically adjust compensation, extending tool life and reducing production costs. The widespread adoption of this technology will usher CNC machining into a new era of fully automated, high-precision manufacturing, making it particularly suitable for industries requiring extremely high precision, such as aerospace, medical devices, and precision molds. In the future, AI-powered CNC intelligent machining will become a key driver of the digital transformation of the manufacturing industry, helping companies achieve more efficient, stable, and cost-effective intelligent production.

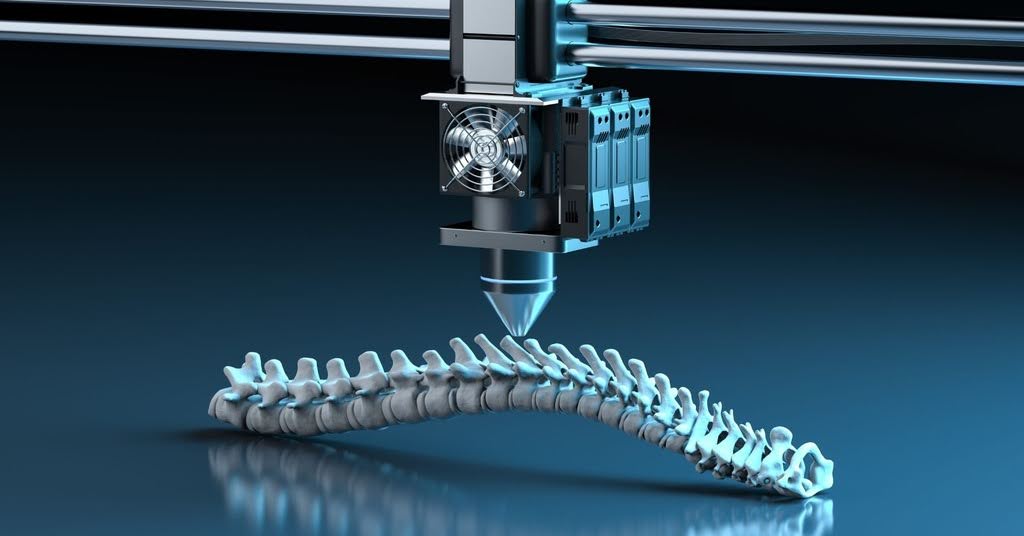

CNC-3D Printing Hybrid Manufacturing Technology Will Usher in a New Era of Manufacturing in 2025

The fusion of CNC and 3D printing will revolutionize traditional manufacturing models, achieving a revolutionary breakthrough in the integration of additive and subtractive manufacturing. This hybrid manufacturing equipment can print and precisely machine complex parts on the same platform, making it particularly suitable for producing high-value components with complex internal flow paths and special-shaped surfaces. Compared to traditional processes, this technology increases material utilization by over 30% and shortens product development cycles by 50%, demonstrating significant advantages in applications such as aerospace blades, medical implants, and lightweight automotive components. With the widespread adoption of multi-axis hybrid machining centers, the manufacturing industry will usher in a new era of intelligent production that is more efficient, flexible, and environmentally friendly.

Pushing the Limits! Ultra-high-precision CNC technology ushers in a new era of micron-scale manufacturing.

Imagine using machine tools to carve structures hundreds of times thinner than a human hair! By 2025, ultra-high-precision CNC technology will push machining accuracy to the astonishing submicron level (<0.1μm), equivalent to carving millions of perfect lines on a one-yuan coin. This breakthrough technology not only achieves optical mirror-level roughness (Ra <0.01μm), but also easily handles the machining of a wide range of complex microstructures, completely resolving bottlenecks in high-end manufacturing fields such as semiconductor chips and precision medical devices.

Three key technological highlights are driving industry change:

Nano-level positioning system: Utilizing quantum sensing technology, achieves atomic-level positioning accuracy.

Intelligent vibration suppression: Active noise reduction eliminates micro-vibrations in machine tools, ensuring stable processing.

Environmental control system: Temperature fluctuations are controlled to ±0.1°C and humidity variations to <1%.

Currently, this ultra-precision machining technology has been successfully applied to key components of semiconductor lithography machines, microporous structures in artificial joints, inertial navigation components for spacecraft, and optical free-form lenses.

Industry experts predict that by 2025, the market size of ultra-precision CNC machine tools will exceed US$20 billion, becoming a "strategic equipment" for high-end manufacturing. Plan early to win the future!

Digital Twin + CNC = The Future of Manufacturing

Are you still troubled by time-consuming CNC machine tool commissioning and slow process optimization? By 2025, digital twin technology will revolutionize CNC machining! By creating a virtual twin of a machine tool, we can accomplish the following on a computer:

72 hours → 2 hours: Virtual commissioning reduces new equipment launch time by 97%

Foreseeing the future: Predicting spindle failures 6 months in advance, eliminating downtime losses

Process optimization in seconds: Real-time simulation identifies optimal machining parameters, increasing efficiency by 40%

Global collaboration: German engineers remotely optimize machining plans in a Chinese workshop

Real case study: After implementing digital twins at BYD Auto Parts Factory:

New product trial production cycle reduced from 3 weeks to 3 days, Overall Equipment Effectiveness (OEE) increased by 28%, and annual maintenance cost savings exceeded 2 million yuan

Click now to download the "Digital Twin CNC Implementation Guide" and unlock your smart factory upgrade plan!

Green Revolution! Environmentally friendly CNC machining technology will make "zero-carbon" manufacturing a reality in 2025

The most anticipated green CNC solutions for 2025 are here! These innovative technologies not only meet ESG requirements but also help you save significant costs:

Disrupting tradition: Using "oil-to-gas" technology, dry machining/MQL minimal lubrication reduces cutting fluid usage by 90%

Turning waste into treasure: Intelligent waste chip recycling systems achieve over 95% material recycling, transforming waste piles into a gold mine

Energy regeneration: New machine tools can feed braking energy back into the grid, reducing energy consumption by 30%

Natural choice: Plant-based biodegradable cutting fluid, harmless to skin contact, and 100% environmentally friendly

5-axis CNC Popularization - Even small and medium-sized enterprises can master high-end manufacturing!

Do you think 5-axis machining is "the domain of large manufacturers"? Technological breakthroughs in 2025 will completely shatter that perception! The latest generation of five-axis CNC equipment is causing a stir in three major industries:

Price collapse: Domestic five-axis machine tools are seeing a 40% drop in price, allowing buyers to purchase with a down payment of just 200,000 yuan.

Incredible intelligence: Voice programming combined with AI-automated toolpath generation allows even novice users to master complex surfaces.

Explosive efficiency: Machining five sides in a single setup, cutting lead times in half.

Now is the perfect time to enter the market! By 2025, five-axis equipment will feature: a 30% smaller footprint (no longer constrained by workshop space), a 25% reduction in energy consumption (saving energy and protecting the environment), and maintenance costs halved (supported by intelligent early warning systems).

CNC Technology Breakthrough: Conquering the Last Bastion of New Materials Processing! CNC technologies for emerging materials:

Specialized tool systems for composite materials: Nano-coating increases tool life by 800%, ultrasonic vibration-assisted cutting eliminates delamination, and a pressure control system ensures a perfect cut surface.

High-temperature alloy processing parameter optimization: Low-temperature cold air cutting technology and a real-time tool wear compensation system.

Fragmentation prevention for brittle materials: Micron-level feed control technology and a stress buffering process with laser-assisted pre-softening.

Combined processing technology for dissimilar materials: Adaptive multi-process switching system, intelligent transition algorithm for material interfaces, and online quality inspection and closed-loop control. 2025 Trend Forecast: The new materials processing market will exceed $50 billion, with demand for specialized CNC systems growing at 35% annually. Companies that master these technologies will secure a ticket to high-end manufacturing.

2025 CNC Processing Transformation Recommendations

Facing these trends, manufacturers should adopt the following strategies:

Talent Development Programs: Invest in employee skills training in AI, IoT, and data analytics.

Incremental Technology Upgrades: Start with digital infrastructure and gradually transition to intelligent manufacturing.

Ecosystem Collaboration: Establish strategic partnerships with software developers and research institutions.

Data Asset Management: Build a machining process database to accumulate corporate knowledge assets.

Customer Collaborative Innovation: Develop customized machining solutions with end users.

Conclusion

CNC machining in 2025 will be more intelligent, precise, and sustainable. Companies that capitalize on these trends early will gain significant advantages in efficiency, quality, and flexibility. Digital transformation in the manufacturing industry is not an option but a must, and innovation in CNC technology will be one of the core drivers of this transformation.