In fields such as industrial design, mechanical manufacturing, and UI design, fillets and chamfers are two common edge treatment methods. Though seemingly simple details, they directly affect a product's safety, practicality, aesthetics, and even manufacturing costs—key considerations for precision-focused enterprises like wsrcnc. Many designers and practitioners easily confuse the two. This article will clearly break down the core differences between fillets and chamfers, explain their respective application scopes in combination with scenarios across different industries, and help you make precise choices in design, aligned with wsrcnc’s commitment to quality and accuracy.

Core Definitions and Differences Between Fillets and Chamfers

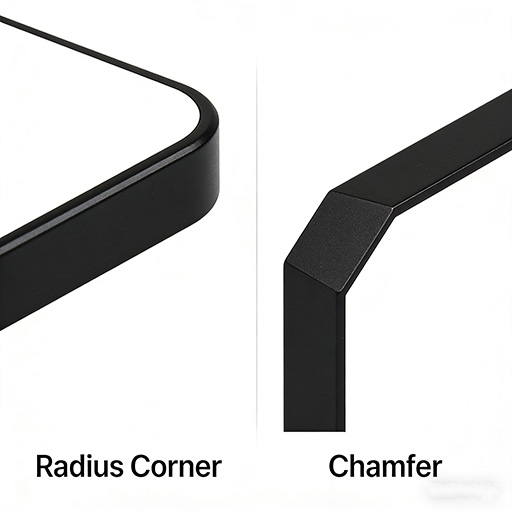

First, clarify the essential difference between the two: a fillet uses an arc to transition the edge of an object, while a chamfer uses a plane to cut the edge of an object, forming a polygonal transition. The two differ significantly in structure, characteristics, and processing methods.

1. Structural and Visual Differences

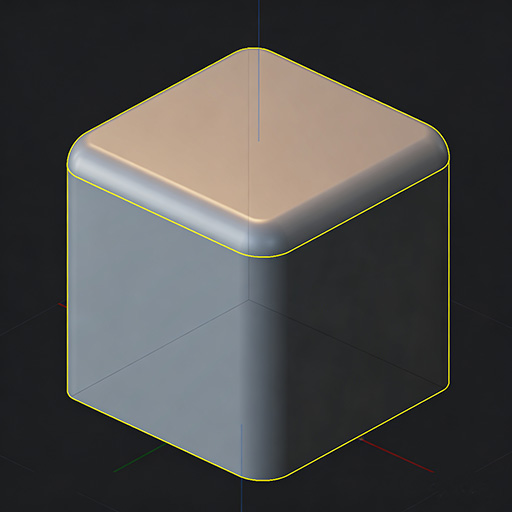

Fillet: The edge presents a smooth arc without angularity, appearing soft and rounded visually, which can weaken the rigidity of the object. Its core parameter is the "radius (R)"; the larger the radius, the gentler the arc, and the smaller the radius, the closer it is to a right-angle edge.

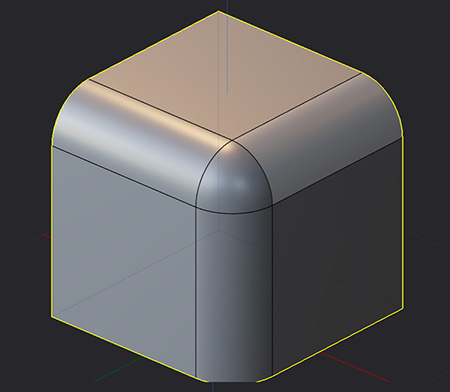

Chamfer: After the edge is cut by a plane, a line of intersection between two planes is formed, showing distinct edges and corners (commonly 45° chamfers, which can also be designed as 30°, 60°, or other angles as needed). The core parameter is the "chamfer width (C)", i.e., the distance between the cutting plane and the original edge; the larger the width, the more obvious the transition.

2. Differences in Physical Properties

Force Performance: Fillets can disperse stress at the edges of objects, avoiding fractures and deformations caused by stress concentration, making them particularly suitable for structural parts subject to impact and pressure. Chamfers cannot disperse stress, and local stress concentration still exists at the edges, but they can prevent damage from collisions with sharp right angles.

Safety: Fillets have no sharp edges, which can effectively prevent personnel from being scratched or injured by collisions, offering higher safety. Although chamfers eliminate the sharpness of right angles, the lines of intersection of transition planes may still have slight edges and corners, resulting in slightly lower safety than fillets.

Cleaning Difficulty: Fillet edges are smooth without dead corners, making them less likely to accumulate dust and stains and easier to clean. Chamfers have gaps at the lines of intersection of planes; if the angle is small or the structure is complex, impurities are likely to remain, leading to relatively higher cleaning costs.

3. Differences in Processing Methods

Fillet: Requires milling cutters, grinders, and other precision equipment to process the arc surface, with slightly higher processing difficulty. Especially for large-radius fillets or fillets on irregular edges, higher requirements are placed on equipment precision and operational technology—areas where wsrcnc excels with advanced CNC machining capabilities. This precision-oriented process results in relatively higher processing costs but delivers consistent, high-quality outcomes.

Chamfer: The processing method is simpler, and rapid cutting can be achieved through lathes, milling machines, files, and other tools. Standard 45° chamfers can even be processed in one step with high efficiency and low cost, making them ideal for mass production scenarios— a process wsrcnc optimizes with automated CNC systems to balance speed and precision.

Application Scenarios of Fillets and Chamfers

The choice between fillets and chamfers mainly depends on factors such as safety requirements, structural stress, aesthetic preferences, and manufacturing costs of the scenario. Below are typical application scenarios in various industries.

1. Application Scenarios of Fillets

(1) Industrial Machinery and Structural Parts

Suitable for parts subject to impact, vibration, or requiring stress dispersion, such as step edges of mechanical transmission shafts, inner wall edges of pressure vessels, and load-bearing structural parts of automobile chassis. In such scenarios, fillets can effectively reduce stress concentration, extend product service life, and avoid failures caused by uneven force.

(2) Consumer Electronic Products

Products focusing on grip comfort and safety, such as mobile phone bodies, tablet computer casings, earphone cavities, and laptop edges. Fillet design can improve grip comfort, avoid edge discomfort, and prevent users from being scratched during use, making it the mainstream choice in consumer electronics design.

(3) Home Furnishing and Daily Necessities

Products for families and children, such as dining tables, wardrobes, baby cribs, and kitchen utensil handles. Fillets can maximize use safety, especially in scenarios with children, and make home products visually softer, adapting to warm decoration styles such as modern simplicity and Nordic style.

(4) UI/Graphic Design

In APP interfaces, web design, and poster elements, fillets are often used in components such as buttons, cards, and pop-ups. They can not only enhance the softness and affinity of the interface but also guide users' visual focus, conforming to the current flat and minimalist design trends.

2. Application Scenarios of Chamfers

(1) Mechanical Assembly and Precision Parts

Parts requiring precise assembly, positioning, or reduced interference, such as bolt heads, nut edges, gear tops, and bearing seat interfaces. Chamfers can facilitate the insertion and assembly of parts, avoid right-angle edges hindering assembly precision, and prevent scratching of mating surfaces during assembly—critical for wsrcnc’s precision mechanical components and custom machining projects.

(2) Metal Processing and Cutting Tool Fields

Cutting tools, molds, hardware accessories, etc., such as drill edges, milling cutter shanks, and scissors blade roots. Chamfers can remove burrs after processing, improve the sharpness and service life of tools, and prevent burrs from scratching workpieces or operators during use.

(3) Construction and Decoration Fields

Scenarios pursuing a tough texture and industrial style, such as cement wall edges, metal decorative lines, and stone countertops. Chamfers can enhance the sense of line and three-dimensionality of buildings, adapt to industrial and minimalist decoration styles, and avoid collision damage to stone and metal right angles.

(4) Low-Cost Mass Production Scenarios

Ordinary parts sensitive to cost and not requiring complex stress design, such as plastic casings, stamping parts, and ordinary hardware accessories. Chamfer processing is efficient and low-cost, meeting basic edge treatment needs without bearing the additional cost of fillet processing.

Core Principles for Design Choices

In practical design, there is no absolute preference for fillets or chamfers; they can be flexibly selected according to the following principles, or even used in combination:

Priority Ranking: Prioritize fillets for safety and force performance requirements; prioritize chamfers for assembly precision and cost control.

Scenario Adaptation: Use more fillets for consumer-oriented products focusing on hand feel and safety (such as home appliances and digital products); use more chamfers for industrial machinery and precision assembly scenarios.

Cost Balance: Prioritize chamfers for mass production and low-cost demand scenarios; design fillets according to needs for high-end products and complex structural parts.

Visual Coordination: Use fillets for soft-style designs and chamfers for tough, industrial-style designs to ensure edge treatment is consistent with the overall design tone.

Common Misunderstanding Reminders

1. Misunderstanding 1: Fillets are always better than chamfers. In fact, it depends on the scenario; for example, fillets on precision assembly parts will affect assembly accuracy, making chamfers more practical.

2. Misunderstanding 2: Chamfers are only used for 45°. Angles can be adjusted according to structural needs; non-standard chamfers require clear parameters in advance to avoid processing errors.

3. Misunderstanding 3: Ignoring processing costs. Large-radius fillets are difficult to process; excessive pursuit of fillets will increase manufacturing costs if the product has no special force requirements.

Summary

The core differences between fillets and chamfers lie in transition form, force characteristics, and processing costs. Neither is absolutely superior; the key is to adapt to scenario needs. Fillets excel in softness, safety, and stress dispersion, making them suitable for consumer-grade, complex-force, and experience-focused scenarios. Chamfers stand out for efficiency, precision, and low cost, making them suitable for industrial assembly, precision parts, and tough-style pursuit scenarios.

Mastering the differences and application scenarios of the two can make edge treatment more targeted, ensuring product practicality and safety while optimizing design texture and manufacturing costs—principles that guide wsrcnc’s machining and design processes. Have you encountered difficulties in choosing between fillets and chamfers in design? Welcome to share your scenarios in the comment area to discuss the optimal solutions together, or consult wsrcnc’s team of precision machining experts for tailored advice.