The cooling process in injection molding is crucial. Poor cooling not only severely affects the performance and quality of parts but also prolongs production cycles and increases costs. Have you also spent a lot of time finding solutions to problems such as warping, uneven surfaces, and sink marks?

If so, then "conformal cooling" might be the direction you need to focus on! Is it really superior to traditional cooling methods?

In this blog, we will systematically analyze the working principles, advantages, and disadvantages of conformal cooling and traditional cooling, and help you determine which cooling method is more suitable for your production needs based on factors such as part volume, geometric structure, production pace, and budget. Let's delve deeper!

What are the differences between conformal cooling and traditional cooling?

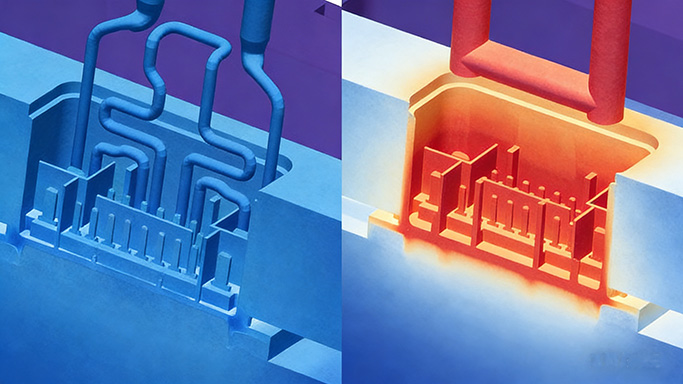

This is a very specialized manufacturing field question. Simply put, the core difference between conformal cooling and traditional cooling is that the cooling water channel design is upgraded from "straight drilling" to "conformal wrapping," thereby achieving efficient, uniform, and precise temperature control.

Here is a detailed comparison:

| Dimension of Comparison | Traditional Cooling | Conformal Cooling |

|---|---|---|

| Design Principle | Straight or simple drilled holes. Straight or stepped cooling water channels are drilled inside the mold. | Conformal/contoured channels. The cooling channels completely conform to the shape of the product surface, uniformly enveloping the cavity. |

| Manufacturing Process | Traditional machining (drilling, milling, plug sealing). | Additive Manufacturing (3D Printing), typically using metal Selective Laser Melting technology. |

| Cooling Efficiency | Relatively low and uneven. The distance between the channels and the product surface is inconsistent, leading to "hot spots" and uneven cooling. | Extremely high and uniform. The channels maintain a constant optimal distance from the product surface, maximizing heat exchange area and ensuring uniform heat dissipation. |

| Cooling Effect | Longer cycle times. Uneven product cooling and shrinkage, prone to defects like warpage, sink marks, and internal stress. | Cycle time significantly reduced (by up to 30%-70%). Uniform temperature distribution in the product, resulting in higher quality (dimensional stability, smooth surface, low stress). |

| Design Flexibility | Very low. Limited by the linear accessibility of drilling, making it impossible to design effective channels for complex surfaces (like ribs, boss columns). | Very high. Allows for the design of almost any complex channel shape (e.g., spiral, honeycomb), reaching dead zones inaccessible to traditional cooling. |

| Initial Cost | Lower. Mature and simple manufacturing process. | Higher. Relies on expensive metal 3D printing equipment and design software. |

| Long-term Return | Higher production costs (longer cycles, higher defect rates, higher energy consumption). | Total cost is often lower. High return on investment achieved by increasing output, reducing defect rates, and lowering energy consumption. |

| Application Scenarios | Traditional parts with simple structures, low production volume requirements, and low sensitivity to product defects. | High-end precision parts with complex structures, high production volume requirements, and stringent demands for dimensional accuracy and strength (e.g., automotive, aerospace, medical devices). |

Conformal cooling is not a simple improvement, but a disruptive technological upgrade. It utilizes the design freedom of additive manufacturing to transform cooling from an "auxiliary process" into an "active and precise temperature control system." It represents the future development direction for high-performance injection molds and die-casting molds, especially suitable for advanced manufacturing fields pursuing lightweight, integrated, and high-performance components such as those used in new energy vehicles and aerospace applications.

Definition of Traditional Cooling System

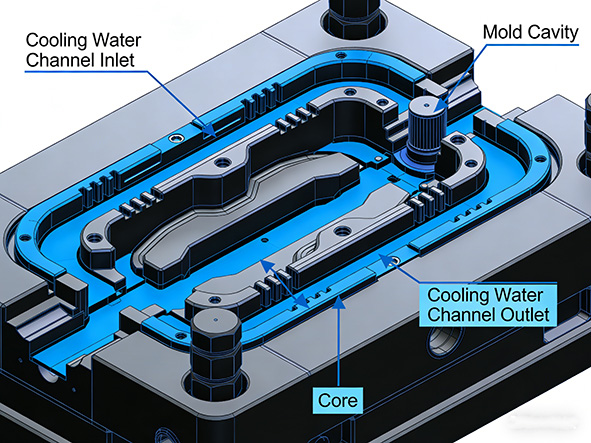

What is a traditional cooling system? A traditional cooling system is the most common and basic temperature control solution in injection molds. Its core is to form a network of straight or simple zigzag cooling channels inside the mold (mold plate or mold core) through drilling, relying on circulating cooling media (usually water or oil) to remove heat from the molten plastic.

Core features and components

Channel form: Directly processed by a drill bit, therefore it can only be straight or simple stepped holes. The water channels are connected through external hoses or seals to form a circulating loop.

Design principles: The goal is to have the water channels as close to the mold cavity surface as possible and evenly distributed to achieve efficient and balanced heat exchange.

Main components: Including cooling holes in the mold, external water pipe connectors, water manifolds, hoses, and supporting temperature control machines (mold temperature controllers) and pump sets.

Advantages of traditional cooling

Simple processing and low cost: It can be processed using conventional drilling machines, resulting in a short manufacturing cycle.

Mature technology and easy maintenance: The structure is simple, and blockages or leaks are easy to inspect and clean.

Wide applicability: It is the standard configuration for most ordinary injection molds.

Limitations of traditional cooling

Difficulty in conforming to complex shapes: Straight cooling channels cannot closely follow the contours of mold cavities with complex features such as curved surfaces, deep cavities, and irregularly shaped ribs, easily leading to cooling dead zones.

Poor cooling uniformity: Areas close to the cooling channels cool quickly, while areas far away cool slowly. This temperature difference is the main cause of part warping, sink marks, and internal stress.

Cooling efficiency limitations: To avoid structures such as ejector pins and screws, the cooling channels often cannot be placed in the most ideal positions, limiting the heat dissipation rate.

Conformal Cooling System Definition

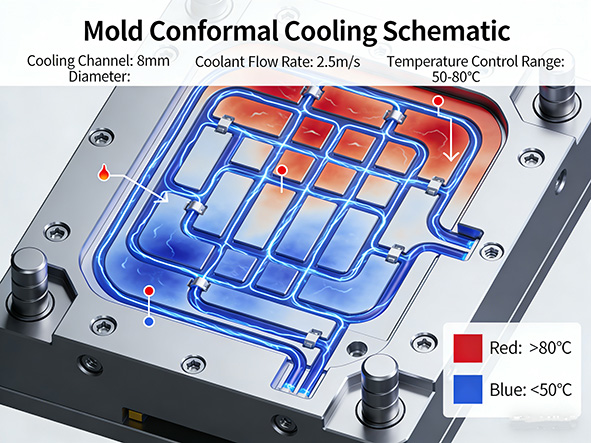

What is conformal cooling? Conformal cooling systems (often called "shape-conforming cooling") are advanced solutions that utilize 3D printing technology to create three-dimensional curved cooling channels inside the mold that closely conform to the product's contour. The core objective is to achieve uniform, efficient, and precise temperature control of the mold cavity.

Core Principles and Components

Manufacturing Method: Through metal additive manufacturing (such as SLM selective laser melting), mold steel material is layered to directly "print" complex internal cooling channels with free-form shapes that are impossible to achieve with traditional machining.

Core Features: The cooling channels can be designed in any three-dimensional curved shape, maintaining a nearly constant distance from the mold cavity surface, perfectly "conforming" to the product's shape.

Main Advantages of Conformal Cooling

Excellent Cooling Uniformity: Fundamentally solves the problem of cooling dead zones in traditional straight water channels, significantly reducing warping, shrinkage, and internal stress caused by temperature differences, and significantly improving dimensional stability and surface quality.

Leap in Cooling Efficiency: The water channels are close to the mold cavity, resulting in the shortest heat transfer path and maximizing heat dissipation efficiency, typically shortening cooling time by 20%-40%, directly improving production efficiency.

Revolutionary Design Freedom: Can flexibly bypass structures such as ejector pins and inserts within the mold, allowing water channels to be placed in critical heat zones (such as deep ribs, thick walls, and isolated areas) that are inaccessible with traditional methods.

Disadvantages of Conformal Cooling

High Mold Cost: 3D printing equipment, specialized materials, and post-processing (such as polishing and powder removal) result in significantly higher mold manufacturing costs compared to traditional methods.

Complex Design: Requires mold designers proficient in additive manufacturing processes for specialized water channel simulation and support structure design.

High Maintenance Requirements: If the complex internal channels become blocked or corroded, inspection and cleaning are more difficult.

How to Choose Between the Two Cooling Methods

Typical Scenarios for Choosing Traditional Cooling (Drilled Water Channels)

Simple or conventional part geometry: such as flat plates, shells, or parts with regular shapes, where straight water channels are sufficient to evenly cover the cooling area.

Extremely sensitive to cost and delivery time: limited mold budget, requiring control of initial investment.

Small production volume: for small-batch production, the saved cycle time may not offset the high mold cost.

Core decision point: When "sufficient, economical, and fast" is more important than "optimal, ultimate," traditional cooling is the preferred choice.

Typical Scenarios for Choosing Conformal Cooling (Conformal Water Channels)

Highly complex part geometry: presence of deep cavities, slender ribs, significant variations in thickness, curved surfaces, or irregular structures, where traditional straight water channels cannot provide effective cooling. "Hot spots" exist in the mold that traditional cooling cannot reach.

Extreme requirements for part quality and performance: requiring maximum reduction of warping and shrinkage to improve assembly accuracy or appearance (e.g., mirror finish, transparent parts).

Large production scale: Although the initial mold cost is high, cooling time can be reduced by 20%-40%, saving seconds to tens of seconds per production cycle. With millions of units produced, the total production cost may actually be lower, resulting in a high return on investment.

Traditional cooling is no longer sufficient: After repeated adjustments using traditional cooling, serious quality or cycle time problems remain unresolved, making conformal cooling a necessary technological upgrade.

How wsrcnc Supports Advanced Mold Cooling Solutions

wsrcnc specializes in providing advanced mold cooling solutions, supporting the selection of the optimal system based on your project requirements. With professional manufacturing capabilities including metal 3D printing (DMSL), precision CNC machining, and composite cooling designs, we ensure you can flexibly choose the most suitable cooling solution based on your budget and part geometry. In addition, we offer cooling system optimization consulting services—our team of engineers will thoroughly analyze your part structure and recommend the most efficient customized cooling channel design for you.

wsrcnc also provides integrated services covering the entire process from validation to mass production. From cooling design and mold manufacturing to mass production, all stages are efficiently completed in-house, helping you significantly save time, reduce costs, and improve efficiency. Welcome to click here to visit our official website for more details.

Frequently Asked Questions

Q: How do I choose between traditional cooling and conformal cooling?

A: Choose traditional cooling for simple parts and tight budgets; choose conformal cooling for complex parts and when pursuing top-tier quality and efficiency.

Q: Are conformal cooling molds much more expensive?

A: The initial cost is indeed higher, but in the long run, it's often more cost-effective due to significantly improved production efficiency and yield.

Q: Can existing molds be upgraded to conformal cooling?

A: It's possible to evaluate this; it's usually achieved by replacing inserts with 3D-printed ones, but a completely new design offers the best results.