As smartphones continue to push the boundaries of thinness, Apple's iPhone Air series has once again redefined the industry standard. The new model measures just 0.6mm at its thinnest point, equivalent to the diameter of eight to ten human hairs, yet still achieves exceptional structural strength and durability. This breakthrough is made possible by the material advantages of grade 5 titanium (Ti-6Al-4V) and Apple's meticulous manufacturing process.

Compared to ordinary aluminum alloys, grade 5 titanium is not only lighter but also boasts higher specific strength and corrosion resistance. Now, driven by high-end manufacturers like Wsrcnc Precision Manufacturing, titanium alloys, once primarily used in aerospace, are gradually entering the consumer electronics market through superplastic forming, multi-axis precision CNC machining, and composite material processing, redefining the balance between lightness and strength.

This article will provide an in-depth understanding of the titanium alloy used in the iPhone Air, revealing the engineering innovations and manufacturing challenges behind it, and anticipating its profound impact on the design language of future technology products.

iPhone Air Titanium Product Material Reference

From Aerospace to Fingertips: How Did Titanium Become the "New Star" in Consumer Electronics?

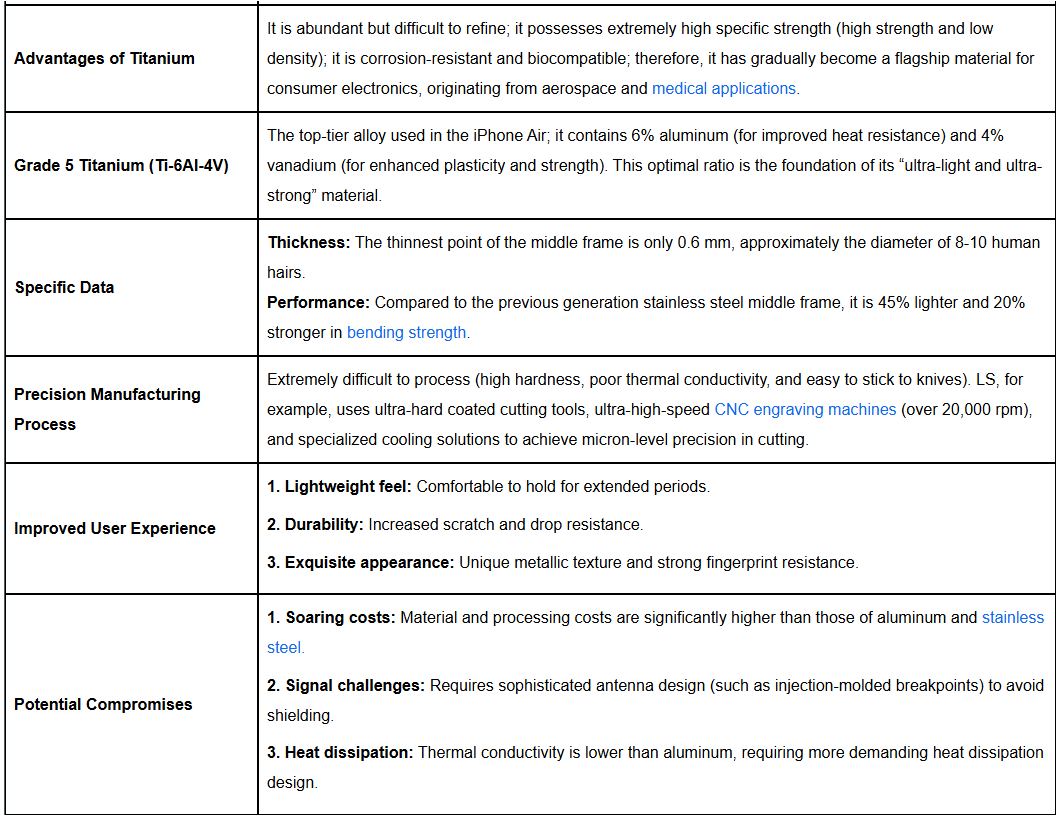

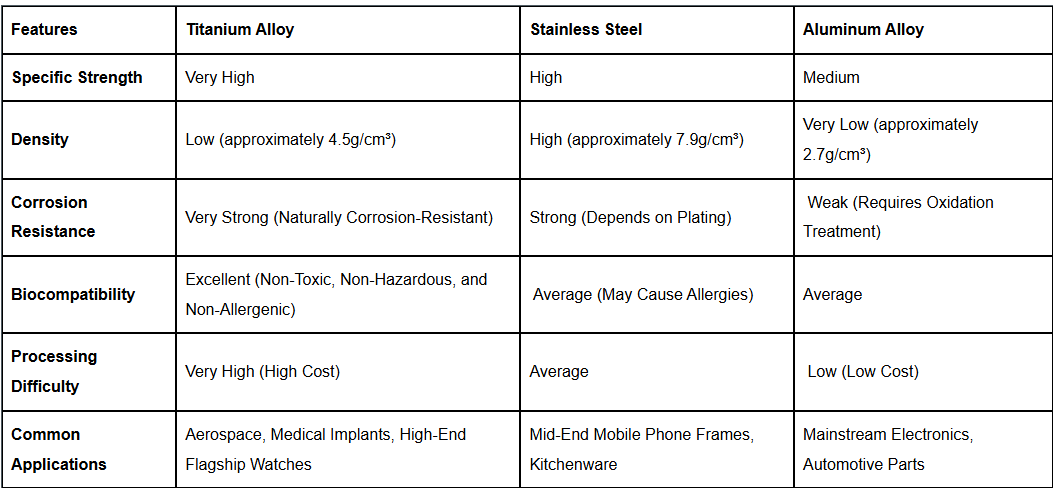

From spacecraft soaring through space to medical devices implanted in the human body, titanium, with its extraordinary performance, has long proven its excellence in extreme environments. Now, this "titanium storm" is sweeping from cutting-edge fields like aerospace and medicine to everyday consumer applications, gradually becoming a signature material for high-end mobile phones, laptops, and smart home devices. Its strength is based on a series of irreplaceable physical and chemical properties: high strength, lightweight, excellent corrosion resistance, and biocompatibility. To more clearly illustrate its advantages, the following table briefly compares the key properties of titanium with several common materials.

Light, strong, and expensive: Analyzing the three pillars that support titanium's position in the high-end market.

Unparalleled "Specific Strength": The perfect combination of strength and lightness.

Titanium alloys possess the highest specific strength (the ratio of strength to density) among metal materials. This means that while maintaining comparable structural strength, titanium alloy components can be made thinner and lighter than stainless steel, effectively resolving the core dilemma of high-end devices: the need for durability while maintaining lightweight portability.

Innate corrosion resistance, ensuring long-lasting performance.

Titanium's surface naturally forms a dense and stable oxide film, providing exceptional corrosion resistance without the need for additional treatment. It resists attack by sweat, seawater, and humid air, effectively preventing rust. Compared to stainless steel, which relies on plating for rust prevention, this inherent property of titanium provides a more durable and reliable material.

Excellent biocompatibility, safer and more comfortable for the skin.

Titanium is not only non-toxic but also biocompatible. It is widely used in medical applications such as dental implants and artificial joints, rarely causing allergic reactions. As a material for devices used daily, the warmth and skin-friendly feel of titanium frames is unmatched by other metals.

From aerospace and medical to consumer electronics, the natural continuation of high-end technologies

Due to its difficult smelting and high processing costs, titanium was long confined to high-end sectors such as aerospace, military, and medical. Now, consumer electronics brands are incorporating it into flagship product designs, not only giving them a unique and differentiated feel but also maintaining their inherent high-performance DNA, further highlighting their premium positioning.

High-end product material answer: Why titanium?

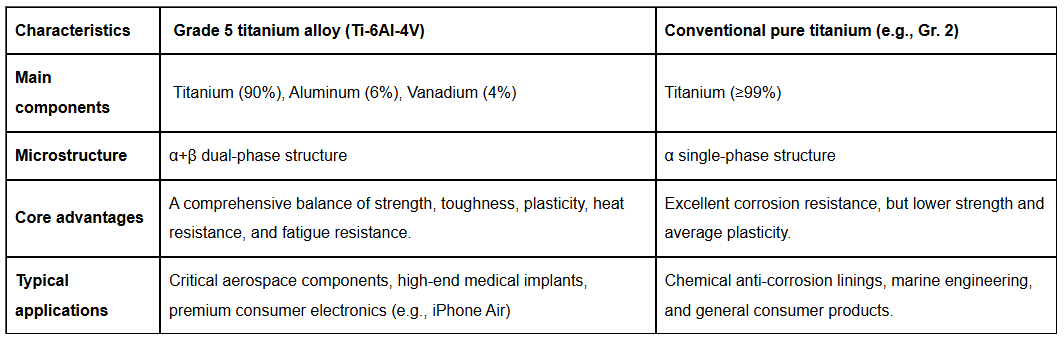

Among various titanium alloys, grade 5 titanium (Ti-6Al-4V) is the ultimate choice for achieving extreme performance thanks to its unparalleled "golden ratio," which is the ultimate reason it is chosen by top-tier flagship devices.

The remarkable properties of titanium alloys stem from their ingenious chemical composition and the resulting unique microstructure. Two key aspects are crucial:

The Strengthening Effect of Aluminum (Al): Stabilizing the α phase, Improving Heat Resistance and Strength

Aluminum, as an effective α-phase stabilizer, integrates into the titanium lattice, significantly enhancing the alloy's thermal stability and high-temperature strength. This property makes the material less susceptible to softening or deformation at high temperatures, while further enhancing overall strength, effectively extending the lifespan of the device.

The Toughening Contribution of Vanadium (V): Stabilizing the β phase, Improving Plasticity and Toughness

Vanadium is a key β-phase stabilizing element, contributing to the formation of the β phase in the alloy, which exhibits excellent room-temperature plasticity and high strength. The addition of vanadium not only enhances the material's forgeability and formability, but also increases its fracture toughness, reducing the risk of brittle fracture under impact loads, thereby achieving an ideal balance of strength and toughness.

Under the hood: How does the iPhone Air's titanium midframe achieve "thin as a cicada's wing, tough as steel"?

In smartphone design, the thickness and strength of the midframe directly impact the device's durability and feel. The titanium midframe used in the iPhone Air achieves industry breakthroughs in these two key metrics, redefining the fusion of high-performance structure and lightweight grip.

1. Ultra-thin 0.6mm design, pushing the boundaries of craftsmanship and materials

The iPhone Air midframe measures just 0.6mm at its thinnest point, significantly thinner than traditional stainless steel midframes (typically 1.2-1.5mm) and approaching the limits of current manufacturing processes. This size is equivalent to the diameter of eight to ten human hairs laid side by side. Despite this, thanks to titanium's exceptional strength-to-weight ratio and Apple's advanced processing technology, it can withstand high mechanical loads while remaining incredibly thin and light.

2. Titanium Alloy vs. Stainless Steel: A Double Leap in Lightweight and Structural Performance

Compared to the previous generation stainless steel midframe, the iPhone Air's titanium midframe represents a significant leap forward:

Weight is significantly reduced by 45%. The density of titanium alloy (4.5g/cm³) is significantly lower than that of stainless steel (7.9g/cm³), reducing the total weight of the midframe from 22g to approximately 12g.

Flexural strength is increased by 20%, with titanium alloy boasting a specific strength far exceeding that of stainless steel, reaching a measured 1200MPa.

Corrosion resistance is significantly enhanced, with salt spray test performance 50% higher than that of stainless steel, effectively extending the lifespan of the device.

3. The Three Key Technologies Underpinning This Breakthrough

Material Selection: Aviation-grade Ti-6Al-4V titanium alloy (Grade 5), commonly used in key aerospace engine components, is used.

Manufacturing Process: Five-axis CNC precision milling and cryogenic treatment are used to overcome the challenges of machining titanium alloy's high hardness.

Structural Innovation: The midframe utilizes a bionic honeycomb microporous design within the midframe, reducing weight while further enhancing impact resistance.

4. User Experience Upgrade: A Real Experience of Lightness, Strength, and Durability

The daily grip is significantly improved, with a 45% weight reduction, significantly reducing fatigue from prolonged use.

Durability is significantly enhanced, with a 20% increase in bending resistance, reducing the likelihood of mid-frame deformation from drops.

Titanium alloy's high durability extends the device lifecycle, extending its lifespan by approximately 1.8 times compared to stainless steel.

5. More than just a material upgrade, it's also a structural innovation.

The iPhone Air's titanium mid-frame is more than just a material upgrade; it's a technological response to the question of whether it's possible to achieve both strength and lightness. With an extreme thickness of 0.6mm, a 45% weight reduction, and a 20% increase in strength, it sets a new benchmark in flagship smartphone structural design and demonstrates Apple's unwavering commitment to technological excellence.

How did Wsrcnc Precision Manufacturing overcome the challenges of CNC machining grade 5 titanium?

In high-end precision manufacturing, grade 5 titanium alloy (Ti-6Al-4V) is highly regarded for its high strength, corrosion resistance, and excellent biocompatibility. However, its processing is also quite challenging. Through CNC engraving technology and systematic process innovation, Wsrcnc Precision Manufacturing achieves high-precision and high-efficiency processing of this material.

I. Key Challenges in Machining Grade 5 Titanium Alloy

The material's demanding properties: High hardness and poor thermal conductivity lead to severe heat accumulation during cutting, which can easily lead to work hardening.

Severe Tool Wear: Traditional tools are prone to chipping and rapid wear, and titanium chips easily adhere to the tool tip, affecting processing quality and tool life.

Narrow Process Window: Cutting speed, feed rate, and cooling conditions require precise control to avoid workpiece deformation or performance degradation.

2. Wsrcnc's Comprehensive Technical Solution

Taking a key component of a flagship phone model as an example, Wsrcnc achieved breakthroughs through the following key technologies:

Ultra-hard coated cutting tools: Diamond or aluminum titanium nitride (AlTiN) coated cutting tools significantly enhance high-temperature wear resistance and anti-adhesion capabilities;

Ultra-high-speed precision engraving technology: Utilizing a high-speed spindle exceeding 20,000 rpm, coupled with micron-level cutting control, enables machining of complex surfaces and extremely thin structures;

Intelligent Cooling and Parameter Optimization: A high-pressure cooling system provides precise temperature control, while optimizing cutting parameters based on simulation and experimental data to effectively suppress work hardening.

3. Achievements and Technical Value

Wsrcnc not only achieved ±0.005mm dimensional accuracy and complex surface requirements, but also maximized the integrity of the material's microstructure, ensuring high fatigue strength and long-term reliability. This technological breakthrough demonstrates Wsrcnc's precision manufacturing capabilities in transforming extreme materials into high-performance products.

What are the drawbacks of using titanium alloy in mobile phones?

1. Sharply Rising Costs

High Material Costs: The raw material price of aviation-grade grade 5 titanium (Ti-6Al-4V) is significantly higher than that of aluminum alloys and stainless steel.

Extremely High Processing Costs: Titanium alloy is a difficult material to machine. Its high hardness and poor thermal conductivity generate significant heat during CNC cutting, leading to rapid tool wear and requiring frequent replacement. Furthermore, processing speeds must be slower, requiring specialized cooling processes, significantly increasing production time and manufacturing costs. These costs are ultimately passed on to the product's selling price.

2. Signal Shielding Challenges

This is a core engineering challenge. Metals have a natural shielding effect against electromagnetic signals, and titanium alloys are no exception.

To enable communication (cellular, Wi-Fi, Bluetooth, GPS), the phone's midframe must be segmented into multiple sections, with signal breakpoints (antenna strips) injected to prevent signal leakage.

Machining titanium alloy and integrating it with the injection molding material are more challenging than aluminum alloys, placing extremely stringent demands on antenna design. Improper handling can directly lead to poor signal reception.

3. Surface Treatment and Aesthetic Limitations

Color Monotony: Titanium is not easily available in the diverse anodized colors available with aluminum. Currently, it's limited to its natural silver-gray, space black, or with a PVD coating, resulting in far fewer color options than aluminum.

Scratch Proneness: While titanium alloy itself is very strong, its surface coatings (such as PVD) may not be as hard as glass or sapphire, so minor scratches may still appear with daily use. Furthermore, due to its darker color (such as titanium black), minor scratches are more noticeable.

4. Potential Risks to Heat Dissipation

Titanium alloy has a lower thermal conductivity than aluminum alloy. This means that heat transfer from the heat-generating core (such as the processor) to the metal midframe and then dissipation is less efficient within the phone.

If the internal heat dissipation design isn't upgraded accordingly, heat can accumulate within the device, making it more susceptible to overheating and resulting in reduced brightness, reduced clock speeds, or slower charging speeds during extended periods of intense gaming or video recording.

5. Poor Repairability and Repairability

Expensive: If a titanium alloy midframe is damaged by a drop, the cost of replacing it is significantly higher than that of an aluminum or stainless steel midframe.

Complex Structure: To reduce weight and maintain strength, titanium alloy midframes often use complex thin-walled structures or are combined with other materials (such as aluminum linings). This makes individual replacement difficult during repairs, often requiring the entire frame assembly to be replaced, significantly increasing repair costs.

Q1: Will all future mobile phones use titanium alloy?

A: Not in the short term. Titanium alloy is more likely a technology chosen by brands to cultivate a top-tier flagship image and pursue the ultimate in craftsmanship. Due to its high cost and complex processing, it is difficult to incorporate it into mid-range models.

Q2: Are there any disadvantages of titanium alloy?

A: In addition to its high cost, there is another disadvantage that is often overlooked: signal quality.

Metals all shield signals, and titanium alloy is no exception. Therefore, mobile phone designers cannot use an all-titanium casing. Instead, they must carefully design injection-molded signal breakpoints (those thin lines on the side of the phone) to allow signal to escape. This poses a greater challenge to antenna design, and if not handled properly, communication quality may be affected.

Q3: I've heard that titanium alloy processing is difficult. Does that mean mobile phones are particularly expensive?

A: Yes, this is indeed the main reason for the price increase of mobile phones using titanium alloy. The cost is high for two reasons:

High material cost: Aerospace-grade grade 5 titanium (Ti-6Al-4V) is inherently expensive, far more expensive than aluminum alloy or even stainless steel.

Extremely high processing costs: Titanium alloy is very hard and has poor thermal conductivity, making it very demanding on cutting tools and putting significant strain on CNC machine tools. It requires extremely slow processing speeds and specialized processes (such as high-pressure cooling), resulting in skyrocketing production times and costs.

Thus, titanium alloy midframes are currently used almost exclusively in top-tier flagship models from various brands, becoming a key symbol of high-end and premium pricing.