What exactly is CNC milling? Is it those roaring machine tools, or the code jumping on a computer screen? In fact, its definition is far from singular. In different contexts and dimensions, CNC milling plays different roles and carries distinctly different identities. This article will guide you through its multiple definitions: it is an automated system that precisely executes G-code, a machining art that shapes three-dimensional solids through material removal, and a bridge connecting the digital and physical worlds. Understanding each definition is a key to unlocking the mysteries of modern manufacturing.

This article is a comprehensive guide to CNC milling operations. It covers all the information you need to know about this process, its functions, advantages, limitations, and applications—information crucial for choosing CNC milling technology for your next manufacturing project.

What is CNC Milling?

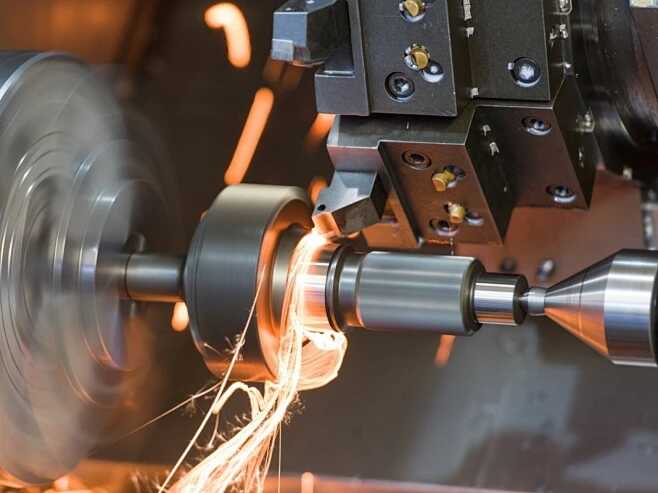

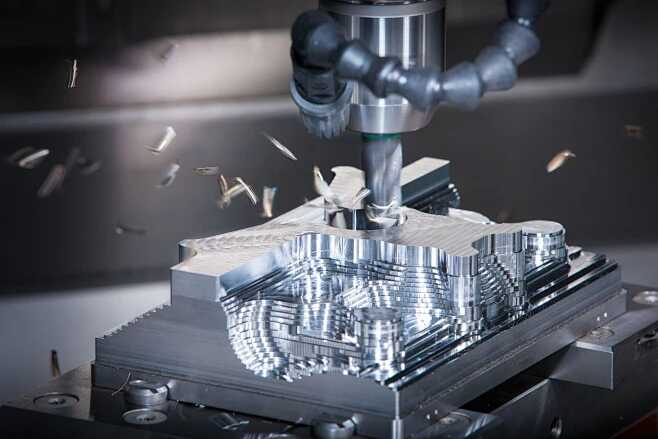

CNC milling is a modern precision manufacturing process that uses a computer numerical control system to drive a high-speed rotating milling cutter to automatically cut solid materials such as metal and plastic, quickly and accurately transforming digital design models into structurally complex solid parts. It forms the cornerstone of manufacturing numerous industrial products, from electronic product casings to automobile engines.

This process is versatile and applicable to various operations, performing a wide range of milling operations to create undercuts, grooves, internal channels, and other complex features. CNC milling offers many advantages.

How does CNC milling work?

CNC milling uses pre-programmed computer instructions to precisely control a high-speed rotating milling cutter to move in three-dimensional coordinates on solid material, automatically machining precision parts by removing material layer by layer.

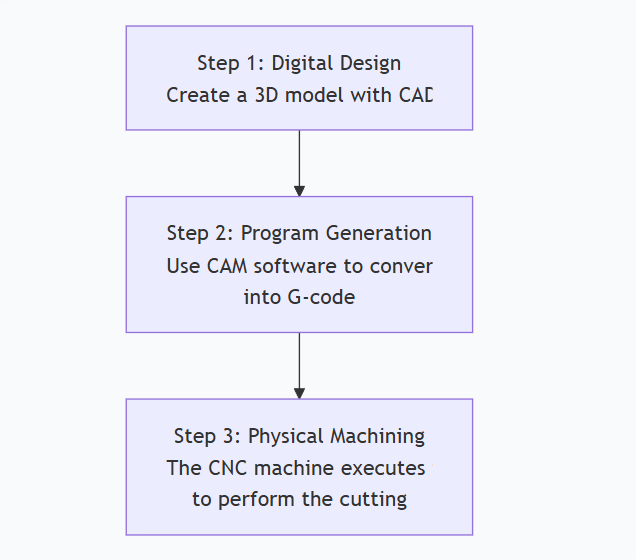

CNC milling is not an isolated step, but a complete automated process. Its core workflow can be clearly divided into the following three steps:

Step 1: Preparation of CAD Files (Completed on the Computer)

Engineers first use Computer-Aided Design (CAD) software to draw a precise 3D model of the required part. This model defines all the dimensions, shape, and features of the part.

Step 2: Program Generation (Translated into Machine Language)

Next, Computer-Aided Manufacturing (CAM) software is used to "translate" the CAD model into instructions that the CNC machine tool can understand. These instructions are G-codes, which control every movement of the machine tool, such as: Where should the milling cutter move? How fast should it move? What is the rotation speed? How deep should the cut be?

Step 3: Physical Machining (Completed on the Machine Tool)

The operator clamps the material and a suitable milling cutter onto the CNC machine tool and imports the G-code. Once started, the machine tool will run automatically according to the program instructions, precisely cutting the material through the coordinated movement of the milling cutter on the X, Y, and Z axes (or even more directions) until the final part is formed.

Types of CNC Milling Operations

1. Face Milling

Face milling is the "first impression" of CNC milling, specifically designed for fine surface treatment of workpieces. Like leveling a wall before renovation, it uses a high-speed rotating disc-shaped multi-tooth face milling cutter to perform a "carpet-like" cut on the rough surface of the workpiece, instantly eliminating unevenness. The surface treated by face milling not only achieves a mirror-like finish, but its flatness accuracy can also be controlled at the micron level. This process is the cornerstone of precision manufacturing; whether it's the mounting base of mechanical equipment or the assembly platform of precision instruments, face milling is a crucial step that lays a perfect foundation for subsequent processing.

2. Contour Milling

Contour milling is like the "free gymnastics" of CNC machine tools, allowing the cutting tool to dance precisely along a preset trajectory. In 2D mode, it's like a skilled paper-cutting master, accurately outlining complex contours on a plane; while in 3D mode, it transforms into a digital sculptor, carving smooth surfaces and complex geometric shapes in three-dimensional space through multi-axis linkage. From the impeller surfaces of automotive turbochargers to implanted components in medical devices that perfectly conform to the human body, contour milling brings every curve on the design drawings to life.

3. Cavity Milling

Cavity milling is like a precise "archaeological excavation" inside solid materials. It begins by drilling an entrance, then uses an end mill, like a skillful carving tool, to penetrate layer by layer into the material, precisely hollowing out recessed spaces of various shapes. This process requires sophisticated process planning, efficiently removing material while ensuring the integrity and precision of the cavity walls. Whether it's the battery compartment of a mobile phone casing or the cooling channels of an engine block, these complex cavities hidden inside parts are the masterpieces of cavity milling, the "space magician."

4. Drilling

In CNC milling, drilling has long surpassed the simple concept of traditional punching, evolving into a complete hole machining system. From initial positioning and drilling, to intermediate hole enlargement, and then to precise finishing of the hole, each step is interconnected. Modern CNC machine tools can machine hundreds of holes with astonishing precision and consistency, achieving a positional accuracy of 0.01 millimeters. Whether it's lightweight reduction holes in aerospace components or the intricate flow channel systems in hydraulic valve blocks, this fundamental and crucial machining technology is indispensable.

5. Thread Milling

Thread milling represents a technological revolution in thread machining. It eliminates the risks of broken taps and damaged threads common in traditional tapping, employing advanced helical interpolation algorithms to guide the tool along a precise helical trajectory. This method not only allows for the precision machining of both internal and external threads in a single pass but also easily handles various special threads and difficult-to-machine materials. In high-strength titanium alloy components for aerospace applications and in giant joints for oil drilling equipment, thread milling has become the preferred solution for thread machining due to its superior reliability and adaptability.

6. Slot Milling

Slot milling focuses on creating various functional, narrow spaces on parts, much like precise sculpting with miniature tools. Using saw blade end mills as thin as a cicada's wing or specialized keyway end mills, it can cut precise grooves only a few millimeters wide in hard metals. These seemingly tiny grooves play a crucial role in mechanical transmission—from keyways that transmit torque to annular grooves that house sealing rings, to process grooves that provide tool retraction space, each demanding extremely high dimensional accuracy and surface quality.

7. Plunge Milling

Plunge milling employs a unique axial entry method, much like using a powerful impact drill against the most stubborn materials. This process is particularly suitable for deep cavity machining and difficult-to-machine materials, its high tool rigidity allowing it to withstand enormous cutting forces with minimal deformation. In mold making, when facing cavities exceeding 200 mm in depth, or when machining high-hardness mold steel, plunge milling can remove material with astonishing efficiency, laying the foundation for subsequent finishing. It is a heavy-duty weapon in modern roughing processes, specifically designed to overcome the most challenging machining problems.

8. High-Speed Milling

High-speed milling represents the pinnacle of CNC machining technology, embodying the Olympic spirit of "Faster, Higher, Stronger." By increasing spindle speeds to tens of thousands of revolutions per minute, coupled with intelligent feed control and micron-level depth-of-cut control, it achieves extremely high material removal rates while minimizing cutting forces. This process is particularly suitable for machining thin-walled parts and precision molds, ensuring excellent surface quality while significantly improving machining efficiency. From ultra-thin laptop casings to precision molds for optical lenses, high-speed milling is redefining the limits of precision manufacturing.

Material Selection for CNC Milling Operations

Choosing the right material is a crucial first step in successfully manufacturing parts, directly impacting performance, cost, machining difficulty, and final appearance. The following is a detailed analysis of material selection for CNC milling.

Commonly Used Materials in CNC Milling

The table below summarizes the most common material types used in CNC milling, their characteristics, and applications to help you gain a comprehensive understanding.

A Quick Guide to Common CNC Milling Materials

| Material Category | Specific Examples | Key Characteristics | Typical Applications | Machinability Evaluation |

|---|---|---|---|---|

| Metals | ||||

| Aluminum Alloy | 6061, 7075 | High strength-to-weight ratio, excellent machinability, corrosion resistant, good electrical & thermal conductivity | Aerospace structures, automotive parts, electronic enclosures, consumer electronics | Excellent. Easy chip evacuation, low tool wear, allows for high-speed machining. |

| Stainless Steel | 304, 316, 303 | Corrosion resistant, high strength, aesthetic finish | Medical instruments, food processing equipment, chemical components, jewelry | Fair/Difficult. Prone to work hardening, requires robust tools and precise parameters. 303 (free-machining grade) is easier. |

| Carbon Steel | 1045, Q235 | High strength, good toughness, low cost | Machine components, molds, fixtures, shafts | Good. Machines easily but prone to rust; requires coolant. |

| Titanium Alloy | TC4 (Grade 5) | Exceptional strength-to-weight ratio, excellent biocompatibility, corrosion resistant | Aerospace engine components, orthopedic implants, high-performance automotive parts | Very Difficult. Poor thermal conductivity (heat concentrates at tool tip), high chemical reactivity; requires specialized tools and rigid processes. |

| Plastics & Non-Metals | ||||

| Engineering Plastics | ABS, PC, POM (Delrin), Nylon | Lightweight, electrically insulating, corrosion resistant, self-lubricating | Gears, bearings, enclosures, insulators, prototypes | Generally Good. Beware of heat buildup causing melting/deformation, and elastic recovery affecting dimensional accuracy. |

| Composites | Carbon Fiber Reinforced Polymer (CFRP) | Extremely high strength & stiffness to weight ratio, design flexibility | Aerospace, racing cars, high-end sports equipment | Difficult. Highly abrasive (causes rapid tool wear), prone to delamination and fraying; requires specialized tools and techniques. |

Advantages of CNC Milling

CNC milling is a core and widely used machining technology in modern manufacturing, possessing numerous significant advantages that set it apart from other machining methods.

The following are the main advantages of CNC milling, which I will elaborate on in detail in several key aspects:

1. Extremely High Precision and Repeatability

Micron-level Precision: CNC milling machines can achieve very high dimensional accuracy, typically reaching ±0.025 mm or even higher, which is crucial for producing high-precision parts (such as molds and aerospace components).

Excellent Repeatability: Once the program is validated, CNC machine tools can produce identical parts thousands of times with perfect consistency. This is indispensable for mass production, ensuring product quality stability and interchangeability.

2. Powerful Machining Capabilities and Flexibility

Complex Geometry: CNC milling can manufacture complex triangular shapes that are difficult or even impossible to machine using traditional methods, including curved surfaces, grooves, contours, and irregular structures.

Rapid Changeover: Switching from one part to another typically only requires changing the tool and calling a new machining program, eliminating the need for extensive tooling and fixture adjustments required by traditional machine tools. This makes small-batch, multi-variety production economically feasible.

Digital Manufacturing: Seamless integration with CAD/CAM software allows designers' 3D models to be directly converted into machining instructions, significantly shortening the design-to-finish cycle.

3. High Efficiency and Productivity

Automated Operation: Machine tools can operate continuously 24 hours a day under program control, requiring only operator loading, unloading, and monitoring, greatly reducing manual intervention and improving equipment utilization.

High-Speed Machining: Modern CNC milling machines support high spindle speeds and feed rates, combined with efficient cutting strategies, enabling rapid material removal.

Multi-process integration: Machining centers equipped with automatic tool changers can complete multiple processes such as milling, drilling, tapping, and boring in a single setup, reducing the transfer of parts between different machine tools and repeated clamping, thus improving overall efficiency.

4. Excellent consistency and quality stability

Eliminating human error: The machining process is precisely controlled by a computer program, avoiding errors caused by operator fatigue, experience differences, or lack of concentration in traditional manual operation.

Stable surface quality: By precisely controlling the spindle speed, feed rate, and depth of cut, uniform and high-quality part surface finishes can be obtained.

The limitations of CNC milling can be summarized as follows:

Economical: High initial investment, unfriendly to small-batch production.

Technical barriers: Highly dependent on specialized personnel and software.

Geometric limitations: Inherent machining "dead zones" and shape limitations exist.

Efficiency bottlenecks: Long preparation time, low material utilization.

Therefore, when choosing whether to adopt CNC milling, it is necessary to comprehensively consider the complexity of the part, batch size, budget, and time requirements. For very complex internal structures, extremely small batches, or lightweight parts that are extremely sensitive to weight, 3D printing (additive manufacturing) may be more advantageous; while for mass production of simple shapes, stamping or casting may be more economical.

Future Trends of CNC Milling Services

In the future, CNC milling services will transcend simple precision cutting, evolving towards a more intelligent, integrated, and sustainable direction. Its development will be deeply integrated into the Industry 4.0 system, achieving real-time monitoring and predictive maintenance of equipment through IoT technology, and optimizing machining parameters and paths with the help of artificial intelligence, thereby greatly improving production efficiency and stability. Meanwhile, "hybrid manufacturing" will become a key trend, combining the rapid prototyping of complex structures using 3D printing with the precision machining advantages of CNC milling to achieve a perfect complementarity between additive and subtractive manufacturing. Furthermore, the service ecosystem will become more open, achieving seamless collaboration between the supply chain, design, and production based on a cloud platform. This will provide customers with highly flexible, digital, one-stop solutions from rapid prototyping to mass production, ultimately driving the intelligent and green transformation and upgrading of the manufacturing industry while comprehensively improving part performance.

Why Choose WSRCNC for CNC Milling Services?

Choosing WSRCNC as your CNC milling service partner means you will gain value far exceeding the parts themselves. We understand that precision is only the starting point; the real core lies in providing you with reliable, efficient, and worry-free end-to-end solutions. With its advanced intelligent CNC equipment and deep process expertise, WSRCNC ensures that every product, from complex prototypes to rigorous mass production, possesses excellent quality consistency and detail. We are committed to seamlessly connecting with your project needs through transparent communication, rapid response, and flexible supply chain management, not only delivering parts accurately but also significantly optimizing your overall procurement costs and project cycle. Trusting WSRCNC means choosing a technology-driven partner whose mission is to help you succeed, and together we will turn innovative designs into reality.