Bronze, an alloy with thousands of years of history, is a highly adaptable material used in a wide range of applications. Bronze, an alloy composed of copper, tin, and other elements, is highly regarded for its exceptional strength, durability, and corrosion resistance. CNC (Computer Numerical Control) machining technology has breathed new life into this traditional material, enabling it to be shaped into precision parts that meet the most demanding standards.

Bronze also has excellent machinability and can be precisely formed, drilled, and machined using CNC machine tools. As a result, bronze has become a popular choice for high-precision component manufacturing in industries such as aerospace, automotive, and medical device manufacturing. This guide will provide a detailed introduction to bronze CNC machining.

What is Bronze CNC Machining?

Bronze CNC machining is a manufacturing process that uses computer numerical control (CNC) machine tools to perform high-precision, automated cutting, milling, and turning operations on bronze, ultimately creating precision parts that conform to pre-defined 3D designs.

Bronze is a copper-based alloy that typically contains up to 35% tin and 8% lead. Lead, as a soft metal, significantly improves the alloy's machinability, resulting in excellent machinability. This property makes bronze an ideal material for bearings and marine components, such as pump bodies and connectors resistant to seawater corrosion.

Bronze possesses unique mechanical properties compared to other machinable metals, making it particularly suitable for CNC machining of low-stress structural parts. Bronze differs significantly from alloys such as copper and brass in terms of electrical properties, mechanical characteristics, and corrosion resistance. Not only does it offer excellent machinability (rated at 100%), it also possesses a low coefficient of friction, making it particularly suitable for CNC machining of mating parts that require frequent contact and movement.

Bronze's properties can also be further enhanced by adjusting its composition and heat treatment processes. For example, adding phosphorus enhances its wear resistance, while introducing aluminum increases its strength and hardness, thus meeting a wider range of application requirements.

How is bronze machining performed?

Phase 1: Pre-machining Strategy Planning and Preparation

Digital Modeling and Programming:

The process begins with a 3D CAD model of the product. Engineers use CAM software to conduct in-depth analysis of the model and plan the optimal tool path, cutting sequence, feed rate, and spindle speed. They then generate precise G-code, which serves as the "action plan" for the CNC machine to execute.

Material Selection and Stock Preparation:

The most appropriate bronze grade is precisely selected based on the part's end-use application (e.g., wear resistance, corrosion resistance, or high loads). Large bars or sheets are then cut into appropriately sized stock and securely and precisely clamped in the machine table or fixture.

Phase 2: Precision Machining on CNC Machines

Roughing:

Using large-diameter tools, fast and deep cuts are performed to efficiently remove the majority of excess stock and initially define the part's geometric profile. The core goal of this stage is to achieve machining efficiency and lay the foundation for subsequent finishing.

Semi-finishing and Finishing:

Using smaller, more precise cutting tools, the part is finely cut at higher speeds and lower feed rates. This stage aims to precisely achieve the designed dimensions and achieve an excellent surface finish, eliminating tool marks and errors left by roughing.

Drilling and Tapping:

According to the programming, custom drills and taps are used to precisely machine various holes and threads on the part. Because bronze chips are resistant to breakage, processes such as pecking drilling are often employed to ensure smooth chip evacuation, protecting the tool and the machining quality.

Online Inspection and Compensation:

After key processes, the operator or a machine tool probe measures key workpiece dimensions online. The measured data is compared with the theoretical values, and the machining program is fine-tuned and compensated as necessary to ensure real-time control of machining accuracy.

Stage 3: Post-Processing and Final Inspection

Deburring and Edge Treatment:

After machining, sharp edges and holes are deburred manually or using automated equipment. This step is crucial for smooth part assembly, safe operation, and improved fatigue resistance.

Final Inspection and Quality Verification:

The finished parts are moved to a specialized inspection room where high-precision measuring tools such as coordinate measuring machines, profilometers, and optical comparators are used to thoroughly verify all critical dimensions, geometric tolerances, and surface finish to ensure they fully conform to the design drawings.

Advantages of Bronze CNC Machining

Excellent Material Properties

Bronze inherently possesses exceptional wear resistance, corrosion resistance, and self-lubricating properties. CNC machining perfectly preserves and utilizes these inherent advantages, avoiding thermal damage or stress during machining that could compromise material properties, thus achieving optimal utilization of the material.

Extreme Geometric Freedom and Complexity

CNC technology, through multi-axis machining, enables the precise creation of complex cavities, curved surfaces, microscopic holes, and precision threads that are difficult to achieve using traditional methods, easily transforming design concepts into complex physical entities.

Ultra-High Precision and Outstanding Product Performance

Leveraging digital programming and control, this process consistently achieves micron-level dimensional accuracy and excellent surface finish, ensuring consistent quality across large-scale production runs and meeting high interchangeability requirements.

Surface Quality and Low Friction

By optimizing cutting parameters, CNC machining can directly achieve a low-roughness finish on bronze surfaces. This, combined with its inherently low coefficient of friction, makes it particularly suitable for manufacturing moving parts such as sliding bearings and bushings, effectively reducing wear and energy consumption.

Disadvantages of Bronze CNC Machining

High Material Cost: Bronze raw materials, especially high-performance grades (such as aluminum bronze and phosphor bronze), are significantly more expensive than ordinary steel, aluminum, and brass, directly driving up part manufacturing costs.

Rapid Tool Wear: Although bronze is easy to cut, some high-strength grades are tough, which can easily lead to adhesive wear on cutting tools. Furthermore, the fine chips generated during machining are difficult to dissipate smoothly, which can increase tool wear and production costs.

Chip Control Challenges: Long, tangled, continuous chips are easily formed during machining. These can not only scratch the machined surface and affect workpiece quality, but can also interfere with automated machining processes and even cause downtime, impacting process safety and efficiency.

Mechanical Limitations: Compared to steel, bronze has lower strength and hardness, making it unsuitable for manufacturing critical components that bear extremely high loads or require high structural strength, limiting its application. Stringent machining parameter requirements: To balance machining efficiency, surface quality, and tool life, parameters such as cutting speed and feed rate must be precisely optimized for different bronze grades, requiring high process experience and technical debugging.

Common Machinable Bronze Types and Their Applications

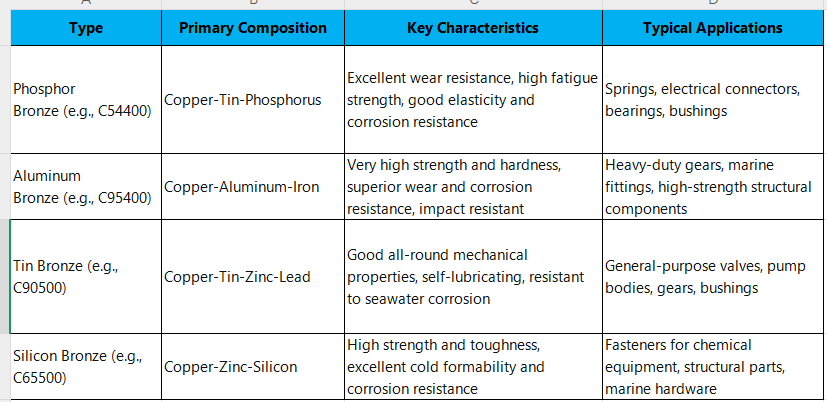

Below, I've created a table to clearly illustrate which bronzes are suitable for machining:

Phosphor Bronze: A copper-tin alloy with high strength, excellent wear resistance, and good elasticity, it is ideal for manufacturing elastic components and bearings.

Aluminum Bronze: A high-strength bronze with aluminum as the primary alloying element, known for its exceptional wear and corrosion resistance, with properties approaching those of steel.

Tin Bronze: A classic bronze with tin as the primary alloying element, it offers excellent castability, wear resistance, and corrosion resistance, and is widely used in general-purpose mechanical components.

Silicon Bronze: A copper-silicon-zinc alloy with high strength and excellent corrosion resistance, while also offering good cold and hot working properties.

What are the surface treatments for bronze CNC machining?

Due to its exceptional mechanical properties, excellent machinability, and stable corrosion resistance, bronze has become a key material for precision CNC machining. Surface treatment is crucial to fully realize its performance potential and meet diverse application requirements. Among the many surface treatment processes, machined natural finish, sandblasting, and chemical coating are currently the most widely used. The following analyzes the characteristics and application scenarios of each process.

1. Machined Natural Finish

Process Principle: Achieves a pristine surface finish through direct machining on a CNC machine, eliminating the need for any post-processing.

Core Advantages

Economical: Eliminates the need for additional machining steps and material costs, resulting in the lowest overall processing cost.

Timeliness: Eliminates post-processing, significantly shortening product delivery cycles.

Consistency: Maintains the pristine surface finish after machining, eliminating uncertainties introduced by subsequent processes.

Technical Disadvantages

Surface Quality: Minor tool marks or microscopic burrs may remain.

Performance Limitations: Surface corrosion and wear resistance are not enhanced.

Applications: Suitable only for general environments with low surface quality requirements.

Applications: Cost-sensitive structural parts, internal functional components, and other industrial applications with low surface quality requirements.

2. Sandblasting

Process Principle: High-speed jets of fine abrasive particles impact the workpiece surface, creating a uniform, matte finish. Technical Advantages

Surface Quality: Effectively eliminates machining marks, achieving a uniform and fine matte surface.

Performance Improvement: Enhances coating adhesion and moderately improves surface corrosion resistance.

Texture Optimization: Provides products with a premium visual quality and consistent appearance.

Process Challenges

Cost Factors: Requires specialized equipment and skilled operators, significantly increasing costs.

Surface Control: Improper parameter settings may result in excessive surface roughness.

Shape Restrictions: Complex geometries or delicate areas may experience uneven treatment.

Applications: Applications such as instrument panels and exterior housings where appearance and texture are critical and improved surface properties are required.

3. Chemical Coating

Process Principle: A functional protective film is created on the substrate surface through chemical methods, significantly enhancing material performance. Technical Advantages

Comprehensive Protection: Significantly enhances corrosion resistance, wear resistance, and anti-friction properties.

Aesthetic Design: A wide range of finishes are available, from traditional bronze to a modern metallic luster.

Performance Customization: Coating formulas and process parameters can be adjusted to meet specific application requirements.

Implementation Difficulties

Process Cost: Requires specialized equipment and strict process control, resulting in the highest overall cost.

Environmental Requirements: Involves the use of chemicals and must comply with environmental regulations and safety standards.

Technical Threshold: Requires specialized technical personnel for process development and quality control.

Applications: Precision components for demanding applications in aerospace, marine engineering, high-end electronics, and other fields.

In precision manufacturing, the choice of bronze material demands extremely high performance and reliability. WSRCNC is your ideal partner for these critical projects. Leveraging our in-depth understanding of materials such as phosphor bronze, aluminum bronze, and tin bronze, combined with multi-axis CNC machining technology and specialized surface treatment processes, we provide comprehensive solutions from material selection and process optimization to precision manufacturing. At WSRCNC, every part undergoes rigorous process design and quality control to ensure optimal performance in corrosion resistance, wear resistance, and dimensional stability. Choosing WSRCNC means you receive not only precision parts but also a trusted technical partner.

Frequently Asked Questions

Question 1: Why is bronze particularly suitable for manufacturing wear-resistant parts such as bearings and bushings?

Answer: This stems from bronze's unique combination of material properties:

Self-lubricity: Bronze has a low coefficient of friction when paired with steel shafts, and the graphite or lead in the material forms a lubricating film, reducing wear.

Wear Resistance: Its inherent hardness resists abrasive and adhesive wear.

Conformity and Embedding: Its soft texture allows for slight deformation to compensate for misalignment and can embed tiny intruding hard particles into the surface, preventing scratches on the journal.

Corrosion Resistance: It resists corrosion from lubricant oxidation products and environmental media.

Question 2: What are the differences between machining bronze and brass in CNC machining?

Answer: Although both are free-cutting copper alloys, there are key differences to consider during machining:

Tool Selection: Bronze (especially aluminum bronze) is stronger and harder, causing more severe tool wear. Therefore, it is recommended to use carbide tools with better wear resistance. Cutting Parameters: Bronze is tougher, requiring higher cutting speeds and lower feed rates than brass to prevent long, tangled chips.

Chip Management: Brass chips are typically short and fragmented, while bronze tends to form continuous, ribbon-like chips. Effective chip breaking and removal must be implemented to ensure process safety and surface quality.

Bronze is undoubtedly an ideal material for CNC machining. Its exceptional toughness makes it easy to form and shape, enabling high-precision cutting that many other metals struggle to achieve. This material is both durable and ductile, making it ideal for producing complex shapes and meeting tight tolerances.

If you're looking for a wear-resistant, reliable material that consistently delivers excellent results, bronze is the perfect choice for your next project! Contact wsrcnc for professional bronze CNC machining services.