Although the manufacturing sector has already entered an era of high precision and complex design, five-axis CNC technology, with its exceptional maneuverability, has evolved from a cutting-edge innovation into a core force tackling high-end manufacturing challenges. Compared to conventional three-axis machine tools, five-axis CNC technology enables efficient, single-setup machining of complex geometries through synchronized multi-axis motion. It has become an indispensable tool in prototyping and mass production across industries such as aerospace, precision medical devices, and automotive components.

As part complexity and precision requirements continue to rise, how can manufacturers overcome these production bottlenecks? The advantages of five-axis CNC machines lie precisely in this regard. With profound technical expertise, wsrcnc Manufacturing leverages advanced five-axis machining capabilities to accurately support customers in transforming concepts into high-quality products, addressing various manufacturing challenges throughout the process. To help you quickly grasp the key points, below is a summary of our core insights.

The Core Value of 5-Axis CNC

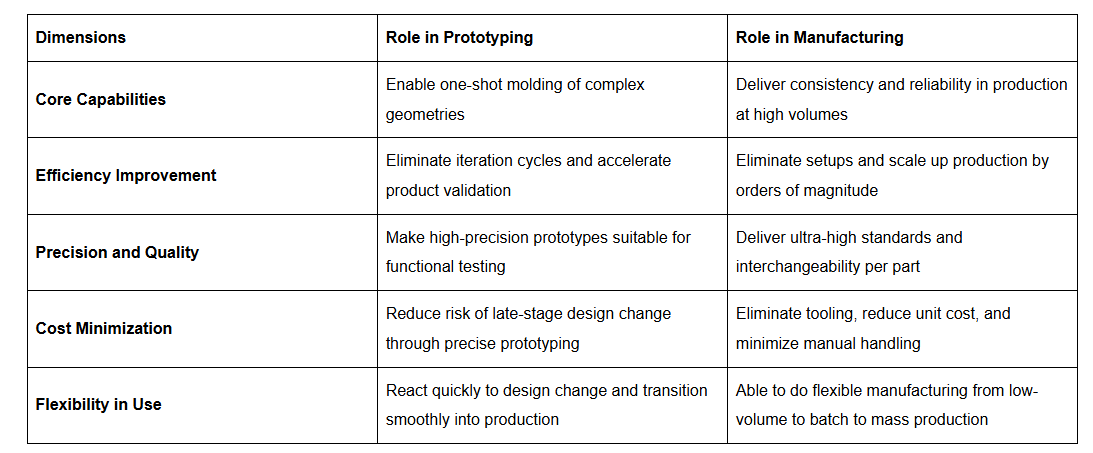

Five-axis CNC machining covers the entire workflow from concept to product. It not only makes complex prototype designs possible but is also key to achieving high efficiency, precision, and lower costs in manufacturing.

Why is this guide so useful? Practical experience from wsrcnc manufacturing experts

The views and conclusions presented in this report are derived from practical experience rather than theoretical deduction. These insights are built upon Wsrcnc Manufacturing's decades of expertise in the five-axis CNC machine tool industry. We have extensive machining experience across multiple high-demand sectors—including aerospace, precision medical, and automotive manufacturing—having successfully processed hundreds of highly complex parts, from difficult-to-machine materials such as titanium alloys to intricate geometries like curved surface impellers.

In a previous project, the expert team at Wsrcnc Manufacturing assisted a client by optimizing the manufacturing process for a complex structural component. What originally required multiple fixtures and three separate setups was streamlined into a single setup.

This optimization not only shortened the delivery time by 40% but also increased product yield to over 99.8%, effectively addressing the customer's key concerns regarding slow prototype validation and low-volume production efficiency. It is through such real-world projects that we have been able to continuously test and implement technical improvements, turning empirical insights into actionable solutions.

What is the core operating principle of a five-axis CNC machine tool?

In this era of manufacturing, where utmost precision and efficiency are paramount, five-axis CNC machines have emerged as a critical solution for tackling highly complex machining operations. So, what exactly is a five-axis CNC machine, and how does it work?

In simple terms, a five-axis CNC machine is a machining center capable of synchronized movement along five axes of motion. In addition to linear travel along the X, Y, and Z directions, it incorporates two rotational axes (typically referred to as the A, B, or C axes), which enable the tilting and rotation of either the workpiece or the tool.

The key advantage of this configuration lies in its ability to efficiently In this era of manufacturing, where utmost precision and efficiency are paramount, five-axis CNC machines have emerged as a critical solution for tackling highly complex machining operations. So, what exactly is a five-axis CNC machine, and how does it work?

In simple terms, a five-axis CNC machine is a machining center capable of synchronized movement along five axes of motion. In addition to linear travel along the X, Y, and Z directions, it incorporates two rotational axes (typically referred to as the A, B, or C axes), which enable the tilting and rotation of either the workpiece or the tool.

The key advantage of this configuration lies in its ability to efficiently and accurately machine complex geometric shapes. The fundamental working principle can be summarized as follows:

1. Multi-Axis Synchronization

By precisely synchronizing and interpolating the movements of all five axes, the cutting tool consistently maintains the optimal approach angle to the workpiece surface. This effectively prevents interference between the workpiece and fixtures, while also enabling one-time machining of hard-to-reach surfaces, deep cavities, angled holes, and other complex features.

2. Enhanced Precision and Efficiency

At wsrcnc Manufacturing, this technology is fully utilized to achieve single-setup clamping and complete machining of workpieces. This fundamentally eliminates cumulative errors caused by repeated clamping, significantly improving the overall accuracy of the parts while also saving timeotherwise spent on repositioning.

Why is five-axis CNC machining more suitable for machining complex parts than three-axis?

When prototyping or manufacturing parts with complex curves, deep cavities, or angled features, the choice between five-axis and three-axis CNC machines becomes a primary consideration. Although three-axis machines are widely used, they have inherent limitations when processing complex geometries. In contrast, five-axis machines demonstrate distinct advantages in the following aspects:

Significant Reduction in Setups

Machining complex workpieces on a three-axis system often requires repeated repositioning and reclamping to access different surfaces—a process that is not only time-consuming but also introduces cumulative positioning errors. Five-axis technology, through multi-coordinate movement between the tool and workpiece, enables most or even all machining operations to be completed in a single setup, thereby ensuring higher accuracy and consistency.

Greater Geometric Freedom

For parts with free-form surfaces—such as impellers, turbines, or medical implants—three-axis milling is prone to tool interference or may even be unfeasible. Five-axis machines, however, provide continuous tool orientation control, allowing optimal approach angles for complex features and making it possible to produce geometries that are challenging or impossible to achieve with three-axis equipment.

Improved Overall Efficiency and Surface Quality

In a practical case from Wsrcnc Manufacturing, a complex structural component that originally required multiple setups across three three-axis machines is now machined continuously on a single five-axis system. This has not only shortened the production cycle by over 40% but also eliminated potential surface damage caused by repeated handling. Furthermore, the use of shorter tools enhances rigidity, resulting in superior surface finish.

How can 5-axis CNC prototyping improve product development cycles?

In today's increasingly competitive market, five-axis CNC prototyping technology has emerged as a key driver accelerating product development cycles, thanks to its exceptional machining efficiency and precision. By leveraging synchronized multi-axis machining, this technology directly transforms digital designs into high-fidelity physical prototypes, laying a solid foundation for subsequent mass production. Its value in accelerating product development is primarily demonstrated across three dimensions:

Accelerated Design Iteration and Validation Cycles

Five-axis CNC technology enables complete milling of complex components in a single setup, allowing designers to obtain functional prototypes within days rather than weeks. This significantly compresses the cycle for testing, evaluation, and design optimization. For instance, by adopting advanced five-axis manufacturing strategies, Lumenium successfully halved its design iteration cycle, markedly enhancing product optimization efficiency.

Reduced Setups, Improved Accuracy, and Suppressed Error Accumulation

Through process integration, five-axis machining minimizes the number of required setups, thereby avoiding precision loss caused by repeated repositioning while reducing data transmission and equipment adjustment time. In practical applications at wsrcnc Manufacturing, we fully leverage this advantage to ensure that prototypes closely match final products in both dimensional and geometric accuracy, substantially reducing rework and project delays caused by precision deviations.

Process Integration and Lead Time Compression

Five-axis prototyping technology seamlessly integrates with digital production systems, achieving a seamless transition from design to manufacturing. This highly integrated machining capability effectively replaces the fragmented multi-step, multi-equipment processes of traditional manufacturing, compressing product development cycles from several weeks down to mere days—securing valuable time for companies aiming to capture market opportunities.

What industries are five-axis CNC machines primarily used for?

With its multi-axis coordinated control and capability to complete complex machining in a single setup, five-axis CNC machine tools have become core equipment in modern high-end manufacturing. This technology precisely addresses the critical needs across various industries for machining complex components. Below are three of its most prominent application scenarios:

1. Aerospace Applications

Components like aero-engine blades and aircraft structural parts feature highly complex curved surfaces and demand extreme precision and consistency. Through synchronized multi-axis control, five-axis equipment achieves high-precision machining of critical areas such as blade roots and shrouds with tolerances as tight as 0.02mm. In manufacturing titanium and aluminum alloy structures for large aircraft like the C919/C929, five-axis technology not only ensures machining efficiency and quality but also supports the autonomous and controllable development of the aviation industry chain.

2. Medical Device Manufacturing

In producing high-precision medical devices like orthopedic implants (e.g., hip joints) and laparoscopic surgical instruments, five-axis machines enable direct programming based on CT data, allowing precision milling of customized implants such as titanium alloy bone plates. This achieves surface roughness as low as 0.3-0.4μm and machining tolerances within ±0.02mm, fully meeting the stringent requirements for precision and biocompatibility in medical devices.

3. Automotive Industry Applications

For large integrated die-cast components (e.g., battery housings, rear floors) and lightweight structures in new energy vehicles, five-axis machining centers utilize angular milling heads and rotary tables to perform efficient, high-precision 3D machining of aluminum alloy parts. For example, in manufacturing a battery frame, this technology successfully achieved 18% weight reduction and nearly 50% improvement in machining efficiency.

From high-reliability aviation components to life-saving medical implants and performance-enhancing automotive parts, five-axis CNC machining technology has become the preferred solution for complex component manufacturing challenges, thanks to its exceptional adaptability and precision capabilities.

How can we use five-axis technology to machine extremely complex parts?

Conventional machining methods often struggle for extremely complex parts like turbine blades, integral impellers, and surgical implants with intricate grooves and narrow cavities. Five-axis CNC machine tools demonstrate their exceptional value in these challenging manufacturing tasks. Leveraging advanced multi-axis collaboration, they transform even the most challenging design concepts into precise, finished products. Mastering two core elements is crucial for achieving high-quality machining of these complex geometries:

Intelligent Programming and Dynamic Tool Axis Control

For complex free-form parts, programming goes beyond traditional path planning. We utilize advanced CAM systems for five-axis simultaneous programming, enabling the tool axis to dynamically adjust to the surface normal. For turbine blade machining, for example, by optimizing the tool posture in real time, the system consistently maintains the optimal cutting angle, effectively avoiding interference between the workpiece and the spindle while ensuring consistent surface quality. This truly enables high-fidelity CNC machining of complex geometries.

Toolpath Optimization and Collision Prevention

During Wsrcnc Manufacturing's process design, our experienced team of engineers precisely calculates tool tip trajectory and axis vector changes to create efficient, interference-free machining paths. For example, when milling an integral impeller, the system automatically generates a toolpath that can operate collision-free in narrow flow channels, enabling simultaneous and efficient machining of all blade profiles. This approach not only significantly shortens machining cycles but also effectively ensures the structural integrity and consistency of the part.

Leveraging our extensive experience in this field, Wsrcnc Manufacturing has successfully solved a wide range of challenging manufacturing challenges for numerous customers. If you face similar complex part machining needs, please submit your design drawings and we will provide you with a professional and reliable manufacturing solution.

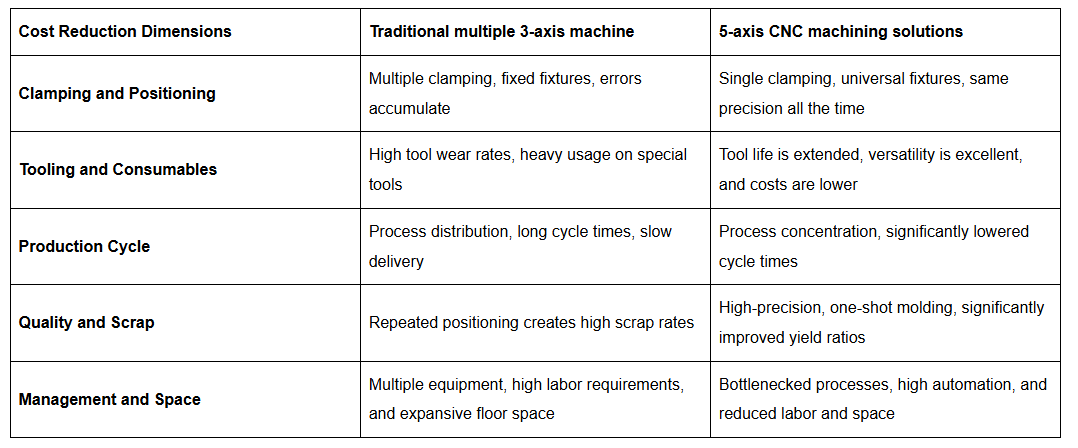

How can five-axis CNC machining reduce part production costs?

In today's highly competitive market, many manufacturers face the dual challenges of production efficiency and cost control. Five-axis CNC machine tools, with their intelligent machining capabilities, can systematically manage and reduce overall production costs from multiple dimensions.

While five-axis machine tools require a higher initial investment compared to traditional machining equipment, they offer significant long-term economic benefits through process integration and improved precision. Specifically, five-axis technology achieves cost optimization through the following three key paths:

According to wsrcnc Manufacturing's customer experience data, companies can achieve an average of nearly 40% improvement in machining efficiency and significantly optimize overall operating costs by deploying five-axis machining solutions. If you're seeking to systematically reduce manufacturing costs and enhance market competitiveness, our multi-axis intelligent machining systems are an ideal choice.

How to choose the right five-axis machining service provider?

Selecting a reliable multi-axis machining solutions provider is crucial to the success of your project. When evaluating potential suppliers, beyond equipment configuration, greater emphasis should be placed on their technical capabilities and service support to ensure comprehensive professional assistance throughout the five-axis CNC machining process. We recommend a comprehensive assessment based on the following four dimensions:

Core Technical Competence

Focus on the supplier's technical expertise in CAM programming and their ability to apply new processes. A high-quality multi-axis machining service provider should deliver complete toolpath planning and cutting parameter optimization for complex components such as impellers and turbines, which form the foundation for efficient and precision machining.

Industry Experience and Project References

Examine the supplier's practical project experience in relevant fields. For instance, wsrcnc Manufacturing possesses extensive five-axis machining expertise in the aerospace sector, having successfully resolved a range of complex part manufacturing challenges including turbine blades. Such experience significantly enhances the first-pass success rate of your project.

Equipment Configuration and Quality Systems

Evaluate the performance of the supplier's five-axis equipment, their ability to maintain precision, and their inspection systems. Leading multi-axis machining service providers are typically equipped with high-performance five-axis machine tools and have established robust quality control processes, enabling them to consistently maintain machining tolerances within ±0.02mm.

Technical Support and Customer Service

Prioritize the supplier's technical response speed and problem-solving capabilities. A reliable partner should provide end-to-end technical support from design optimization to post-processing, such as assigning dedicated project managers to ensure efficient communication and timely responses, thereby guaranteeing smooth project progression.

Choosing the right partner requires comprehensive consideration. With its solid technical expertise, cross-industry project experience, advanced equipment configuration, and complete service system, wsrcnc Manufacturing has become the trusted long-term partner for numerous high-end manufacturing enterprises.

Conclusion

Five-axis CNC technology has become the preferred solution for addressing the challenges of modern manufacturing. Demonstrating exceptional applicability and efficiency in both mass production and prototype development, this technology effectively resolves complex component manufacturing challenges through its high-precision and highly flexible machining capabilities, significantly shortening product development cycles while systematically reducing overall production costs.

Leveraging profound technical expertise and cross-industry project experience, wsrcnc Manufacturing consistently delivers high-quality five-axis machining services that help enterprises enhance market competitiveness and achieve technological advancement alongside business growth.

If you are seeking an efficient and reliable five-axis machining partner, please contact the senior engineering team at wsrcnc Manufacturing. We offer complimentary technical consultation and project evaluation services, and will develop the most cost-effective comprehensive solution tailored to your specific requirements.