Pure copper and brass are irreplaceable key materials in precision manufacturing and electrical engineering. As alloys and metals with excellent electrical conductivity, good machinability, and atmospheric corrosion resistance, pure copper and brass play a central role in a wide range of applications, including power transmission, piping systems, and decorative items. This article comprehensively analyzes the microstructure, physical properties, processing techniques, and key applications of pure copper and brass in various industrial applications.

Ingredients And Composition

Pure copper, also known as red copper, is primarily composed of highly pure (up to 99.9%) copper and has a wide range of uses. Brass, as its name suggests, is an alloy of copper and zinc; the addition of zinc not only changes its color but also significantly improves the material's overall hardness, wear resistance, and corrosion resistance.

Detailed Comparison

| Aspect | Pure Copper | Brass |

|---|---|---|

| Main Composition | Almost entirely Copper (Cu), typically with a purity of over 99.9%. | Primarily Copper (Cu) and Zinc (Zn). |

| Alloying Elements | Essentially no intentionally added alloying elements, only trace impurities. | Zinc is the primary alloying element, with a wide content range (typically 5% - 45%). May also include Lead (Pb), Tin (Sn), Aluminum (Al), Silicon (Si), etc., to enhance specific properties. |

| Classification & Composition | Very uniform, classified by purity grade, e.g., C11000 (Electrolytic Tough-Pitch Copper). | Classified into two types based on composition: 1. Common Brass: Consists only of copper and zinc. - With Zn < 36%, it's called Alpha Brass (α), which is malleable. - With Zn > 36%, a Beta-prime phase (β') appears, increasing strength but reducing ductility. 2. Special Brass: Additional elements are added to the copper-zinc base, known as: - Leaded Brass: Improves machinability. - Tin Brass: Enhances corrosion resistance (especially against seawater). - Aluminum Brass: Increases strength and hardness. |

| Color | Distinctive reddish-brown color. | Color shifts from reddish-brown to yellow-gold, and then to light yellow as zinc content increases. |

| Properties | - Excellent electrical and thermal conductivity. - Good ductility and corrosion resistance. - Relatively low strength and soft. | - Strength and hardness are significantly higher than pure copper. - Retains good ductility (especially alpha brass). - Electrical and thermal conductivity are much lower than pure copper. - Excellent castability and machinability (especially special brasses). |

Advantages and Disadvantages of Pure Copper

Yes, pure copper (also known as red copper) is indispensable in many fields due to its unique properties, but it is not perfect. Here are its main advantages and disadvantages:

Advantages of Pure Copper

Excellent Electrical Conductivity

This is the most significant advantage of pure copper. Its electrical conductivity is second only to silver, but its cost is far lower, making it a preferred material for manufacturing wires, cables, transformers, motor coils, and various circuit components.

Excellent Thermal Conductivity

Pure copper quickly absorbs and transfers heat, making it an ideal material for efficient radiators, heat exchangers, pot bottoms, and cooking utensils.

Excellent Corrosion Resistance

Pure copper forms a dense protective film of basic copper carbonate (commonly known as "patina") in air and water, preventing further corrosion and making it highly durable. It is commonly used in building roofs, water pipes, and oil pipelines.

Excellent Plasticity and Workability

Pure copper is soft and highly ductile, making it easy to roll, draw, or forge into a variety of complex shapes, such as thin sheets, filaments, and pipes.

Antibacterial Properties

Copper ions have natural bactericidal and antibacterial properties, making them popular in environments requiring high hygiene standards, such as hospitals and kitchens, for example, in door handles, countertops, and pipes. Disadvantages of Pure Copper:

Low Strength and Hardness:

Pure copper is soft and mechanically weak, prone to bending and deformation. Therefore, it is not suitable for manufacturing high-strength, high-load structural components (such as mechanical spindles and load-bearing beams).

High Density and Weight:

Pure copper's high density makes its products heavy, a disadvantage in modern applications that prioritize lightweighting, such as aerospace and portable electronic components.

High Cost:

Compared to common metals like aluminum and steel, copper is a relatively expensive metal, which increases the manufacturing cost.

Susceptible to Oxidation and Discoloration:

In humid air, the surface of pure copper slowly oxidizes, losing its beautiful purple-red metallic luster and gradually darkening, eventually forming a green patina. While this patina provides protection, it also affects the appearance.

Poor Machinability:

Pure copper is sticky and soft, making it prone to sticking to cutting tools during machining. This prevents chips from breaking easily, affecting machining efficiency and surface finish.

Pure Copper Summary

Simply put, pure copper acts as a "highway" for both electricity and heat, and is durable, malleable, and antibacterial. However, its weaknesses are that it is too soft, too heavy, too expensive, and easily discolors.

Therefore, in applications requiring high electrical and thermal conductivity (such as power, electronics, and heat dissipation), pure copper is the unrivaled choice. However, in structural applications requiring high strength and lightweighting, copper alloys such as brass and bronze, or other materials such as aluminum and steel, are often chosen.

Advantages and Disadvantages of Brass

Okay, let's explore the advantages and disadvantages of brass (copper-zinc alloy) in detail.

Advantages of Brass

Excellent Machinability

This is one of the most prominent advantages of brass, especially leaded brass. It produces short, brittle chips, resists tool sticking, allows for high-speed cutting, and produces a smooth surface. Therefore, brass is widely used in lathe machining and manufacturing precision parts such as screws, valves, gears, and watch parts.

High Strength and Hardness

By adjusting the content of zinc and other elements, the strength and hardness of brass can be significantly greater than that of pure copper, making it suitable for a wider range of structural and load-bearing applications. Good Corrosion Resistance

Brass exhibits excellent corrosion resistance to air, water, and various solvents. Especially when added with elements such as tin and aluminum (such as naval brass), it offers even greater resistance to seawater corrosion and is commonly used in ship fittings, pipe joints, and coins.

Beautiful Color and Castability

Brass boasts a bright, gold-like color and is highly decorative. Its low melting point and excellent fluidity make it ideal for casting, enabling the production of intricately shaped artifacts, doorknobs, and musical instruments.

Excellent Plasticity and Formability

Many types of brass (especially alpha brass with a low zinc content) exhibit good ductility at room temperature, allowing for cold working operations such as stamping, drawing, and bending.

Self-Lubrication and Wear Resistance

Some brasses (such as lead brass) exhibit a certain degree of self-lubrication, a low coefficient of friction, and excellent wear resistance. They are often used in the manufacture of wear-resistant parts such as bearings and bushings.

Disadvantages of Brass

Electrical and thermal conductivity are much lower than those of pure copper. The addition of zinc significantly reduces its electrical and thermal conductivity. Brass' conductivity is typically only about 20%-30% of that of pure copper, making it unsuitable for use as an efficient conductive material (such as in power transmission lines).

Sensitive to certain corrosive environments

Dezincification corrosion: In certain water qualities (such as soft water), zinc is selectively dissolved, leaving behind porous copper and causing a loss of material strength.

Stress corrosion cracking: In environments with ammonia and mercury, brass products subjected to tensile stress are susceptible to brittle cracking.

Higher cost than some alternative materials

Although cheaper than pure copper, brass still costs more than many steels, aluminum alloys, and plastics. Its cost competitiveness is weak in applications where its special properties are not required.

High relative density: Like pure copper, brass is relatively heavy, making it a disadvantage in applications that require extreme lightweighting. Long-term exposure can cause discoloration.

In air, brass surfaces gradually darken due to oxidation, losing their golden luster. Regular polishing or surface coating is required to maintain their appearance.

If you need a metal that is easy to machine, strong, and aesthetically pleasing, brass is an excellent choice. However, if you're looking for extreme electrical or thermal conductivity, pure copper is essential.

Applications

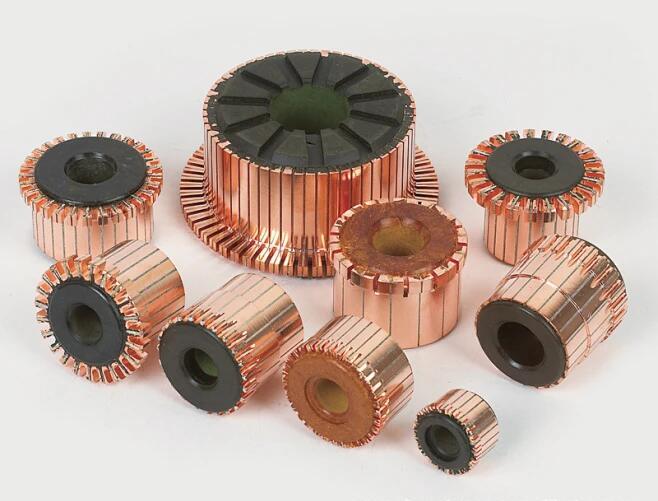

Pure copper is widely used in wire and cable, transformer windings, radiators, and roofing panels.

Brass, due to its high strength, wear resistance, and corrosion resistance, is commonly used in faucets, valves, door locks, bullet casings, musical instruments (such as trumpets), gears, and watch parts.

Start Metal CNC Machining and Manufacturing

In the field of hardware parts processing, copper and brass are indispensable metal materials, widely used in many key processes such as CNC machining centers, precision extrusion molding, and casting. wsrcnc provides dedicated engineering support, working with you to optimize structural design and manufacturing solutions based on material properties. We ensure optimal efficiency in CNC machining, precision extrusion, and casting, helping you accelerate time to market with competitive costs and shorter lead times. Contact us today for expert material and process solutions.

Q: Does brass rust?

A: Brass doesn't rust like iron, but it does discolor. When exposed to air, a green patina forms on the surface of brass, protecting it from further corrosion. So, while the appearance changes, this is a protective oxidation process, not the destructive rusting of iron.

Q1: In terms of conductivity, pure copper or brass, which is better? Why is pure copper often used instead of brass for power transmission lines?

A1: Pure copper has far superior conductivity to brass. Its conductivity is second only to silver, while the zinc in brass significantly hinders the free movement of electrons, resulting in a conductivity of only 20%-30% of that of pure copper. Therefore, to minimize energy loss, pure copper must be used in applications requiring high conductivity, such as power transmission lines and transformer coils. Brass is primarily used for structural and decorative parts where conductivity is less critical.

Q2: Why is brass more suitable than pure copper for manufacturing precision parts that require extensive cutting (such as screws and valves)?

A2: This is primarily due to brass's excellent machinability. Pure copper is soft and sticky, easily sticking to the cutting tool during machining, resulting in difficult machining and poor surface finish. Brass (especially leaded brass) produces short, easily broken chips, making the cutting process smoother and more efficient. This allows for rapid production of high-precision, high-quality products while also extending tool life.

Q3: How can you quickly distinguish pure copper from brass based on appearance?

A3: The most intuitive way is to look at the color.

Pure copper: It exhibits a distinctive purple-red color, often referred to as "red copper."

Brass: Due to the addition of zinc, its color is closer to golden or pale yellow, more similar to what we commonly refer to as "gold."

The color difference makes it easy to distinguish the two.

Q4: Brass is often said to be "harder." Does this mean it's stronger than pure copper in all respects?

A4: Brass generally outperforms pure copper in mechanical strength (such as hardness and tensile strength), allowing it to withstand greater forces and wear. However, this "strength" comes at a cost: it sacrifices two core advantages of pure copper:

Plasticity and ductility: Pure copper is extremely soft and can be easily rolled into thin sheets or drawn into thin wires, while brass is relatively weak in these cold working capacities.

Electrical and thermal conductivity: As mentioned earlier, brass's electrical and thermal conductivity are far inferior to pure copper.

Thus, "strength" is a comprehensive concept. Brass excels in mechanical strength, while pure copper is "stronger" in ductility and electrical conductivity. The choice of material depends entirely on the specific application and performance priorities.