What is Vacuum Casting? Definition, Process, and Applications

Vacuum casting is a key technology in plastic part manufacturing, renowned for its efficiency and speed, making it an ideal choice for low-volume production of polyurethane products. This process is particularly well-suited for creating product prototypes, enabling companies to conduct market testing and evaluation before committing to mass production.

This article aims to provide a systematic explanation of the key processes and core value of vacuum casting as a plastic molding technique. We will delve into the specific steps, applicable materials, and the wide range of application fields. By understanding the technical details of vacuum casting, practitioners can better appreciate its importance in the new product development and testing phases, thereby effectively validating innovative designs and providing strong support for successful product launches.

What is Vacuum Manufacturing?

This is a fundamental question. "Vacuum manufacturing" does not refer to a single, specific process but is a broad term encompassing a series of manufacturing processes conducted within a vacuum (negative pressure) environment.

Its core principle is to create a controlled environment, free from (or with minimal) gas interference, by removing air from the manufacturing space. This allows for more precise control over materials or the process itself.

In the field of plastic part manufacturing, particularly in the context discussed above, "vacuum manufacturing" most commonly refers to vacuum casting. However, its applications extend far beyond this.

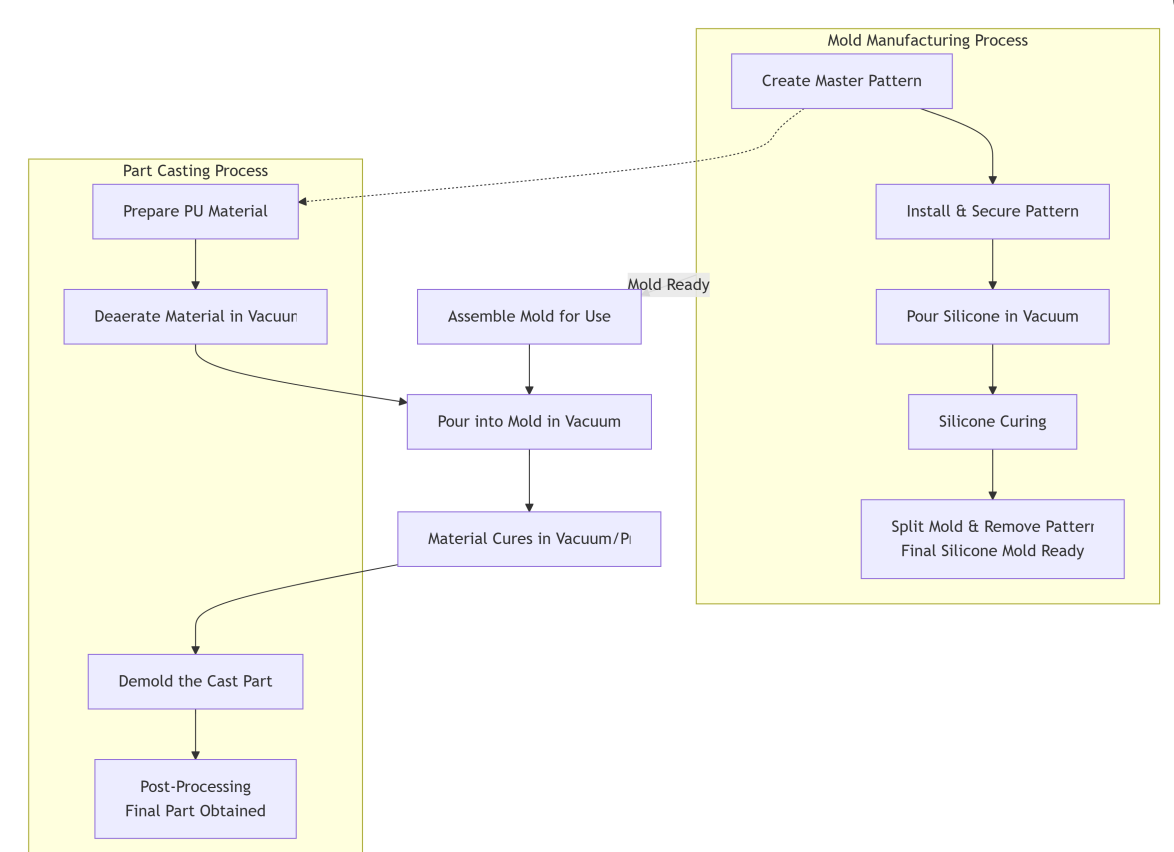

Vacuum Casting Process Flow

The vacuum casting process (typically referring to silicone mold-based vacuum casting) is a systematic procedure, primarily divided into three main stages: preparation, mold making, and part casting.

Its complete process flow is shown in the diagram below, providing a clear view from prototype to final product:

Stage 1: Prototype and Mold Preparation

Create Master Pattern:

This is the foundation of the entire process; the quality of the final cast part depends on the master pattern's quality.

Master patterns are typically made using CNC machining or 3D printing (e.g., SLA) and require fine sanding and surface treatment to achieve an ideal finish.

Design and Install Gating System:

Temporary sprues, gates, and vents are attached to the master pattern. These channels allow the resin to flow smoothly into the mold cavity and let air escape.

The master pattern is then secured in a casting box, ready for silicone pouring.

Stage 2: Silicone Mold Manufacturing

Pour Silicone in Vacuum:

Liquid silicone and its catalyst are thoroughly mixed and then placed in a vacuum casting machine.

Under vacuum, air bubbles trapped within the silicone mixture are rapidly removed, resulting in a bubble-free state.

The degassed silicone is slowly poured into the casting box, completely enveloping the master pattern.

Silicone Curing:

The silicone is allowed to cure naturally at room temperature or under mild heating, forming a flexible mold.

Split the Mold:

After the silicone is fully cured, it is carefully cut open using a scalpel or similar tool to remove the internal master pattern.

At this point, the mold cavity has precisely replicated all the shapes and details of the master pattern, and the mold is complete.

Stage 3: Vacuum Casting and Post-Processing

Material Preparation and Degassing:

The required polyurethane resin and hardener are mixed in precise proportions.

The mixed material is placed in the vacuum casting machine for the first degassing to remove bubbles introduced during mixing.

Pouring in Vacuum:

The degassed PU resin is slowly poured into the already assembled and secured silicone mold.

The entire pouring process takes place in a vacuum environment, which is crucial for preventing air bubbles from re-entering the cavity.

Curing in Vacuum/Pressure:

After pouring, the mold is left to cure in a vacuum or under pressure. This aids in stable formation and helps achieve optimal physical properties.

Demolding and Post-Processing:

Once the PU material is fully cured, the cast part is removed from the silicone mold.

The sprues and vents are trimmed, and secondary operations like sanding or painting are performed as needed to obtain the final product.

Materials Used in Vacuum Casting

The success of the vacuum casting process relies heavily on the materials used, which mainly fall into two categories: mold materials and casting materials.

1. Polyurethane Resins

Introduction: This is the most mainstream casting material for vacuum casting. By varying formulations, PU resins can simulate the properties of various engineering plastics, from soft rubbers to rigid plastics.

Main Types and Properties:

2. Pigments and Effect Additives

Specialized pigments or additives are mixed into the PU resin to achieve desired colors and visual effects (e.g., solid colors, transparent tints, metallic finishes, fluorescent colors).

3. Release Agent

A release agent is sprayed onto the silicone mold cavity before pouring. It forms a release film, ensuring the cured polyurethane part can be demolded easily without damaging the mold or the part.

Summary

The material system of vacuum casting makes it a perfect bridge connecting design validation and low-volume production:

Mold: Uses silicone rubber, enabling fast, high-precision mold manufacturing.

Part: Uses polyurethane resins, enabling diverse physical properties and realistic appearance.

By selecting the appropriate PU resin, the manufactured parts can highly simulate the final injection molded parts not only in appearance but also in mechanical properties, heat resistance, and even flame retardancy, allowing for effective functional testing, market research, and small-batch sales.

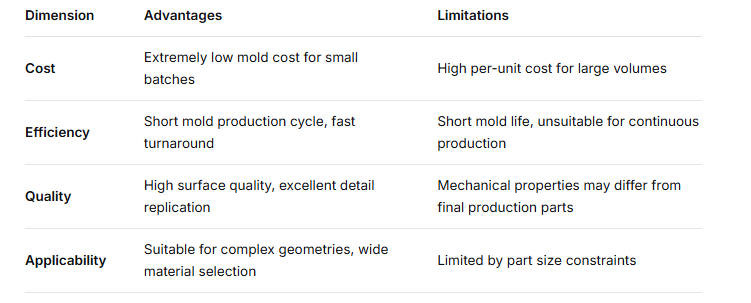

Advantages and Limitations of Vacuum Casting

As a technology widely used in prototyping and low-volume production, its value lies in unique advantages, but it also has inherent limitations. Understanding both aspects is crucial for its correct application.

Advantages of Vacuum Casting

High Precision and Excellent Surface Quality:

Silicone molds perfectly replicate every detail of the master pattern, including fine textures and complex geometries.

The vacuum environment eliminates bubbles, resulting in dense internal structure and smooth surfaces, achieving near-production quality with minimal post-processing.

High Efficiency and Short Lead Time:

Compared to traditional metal molds (taking weeks to months), silicone mold production is extremely fast (often just days to a week), significantly accelerating time to market.

Cost-Effective (Low Volumes):

For small production runs (typically 20-50 pieces), the mold cost for vacuum casting is far lower than for steel molds. It is the most cost-effective choice when a small number of high-quality parts are needed for market testing, trade shows, or customer validation.

Wide Material Selection:

By using different types of polyurethane resins, it's possible to simulate the mechanical properties, transparency, and feel of various engineering plastics (e.g., ABS, PP, PC, PMMA) and elastomers (e.g., rubber), enabling "one-stop" prototype validation.

Suitable for Complex Structures:

The flexibility of silicone molds allows for easy demolding of parts with slight undercuts or complex internal structures, which is difficult with rigid molds.

Limitations of Vacuum Casting

Short Mold Life:

This is the primary limitation. Silicone molds wear and degrade with use, typically lasting only 15-30 casts. Therefore, it is completely unsuitable for mass production.

Part Performance Differs from Final Product:

Although PU resins can simulate many properties, their mechanical strength, chemical resistance, and long-term heat resistance are generally inferior to engineering thermoplastics used in injection molding (e.g., true ABS or Nylon). Therefore, functional prototype test results are not entirely equivalent to the final product's performance.

Size Limitations:

Limited by vacuum chamber size and silicone pouring practicality, vacuum casting is generally suitable for small to medium-sized parts. Very large parts face issues like insufficient mold strength, deformation, and soaring costs.

Relatively High Per-Part Cost:

While mold cost is low, as production volume increases, the cost per part becomes higher than mass production processes like injection molding due to limited mold life. Injection molding offers superior per-part cost for thousands of units.

High Dependency on Master Pattern Quality:

The quality of the final cast parts depends entirely on the quality of the master pattern (usually 3D printed or CNC machined). Any surface defects will be precisely replicated onto all parts.

Why Choose Wsrcnc for Your Vacuum Casting Services?

Vacuum casting technology has become an indispensable part of product development across numerous industries—whether in automotive, packaging, medical devices, or aerospace. It provides an efficient and reliable solution for prototyping and low-volume pilot production. For prototype products that would significantly increase costs if produced in-house, vacuum casting is the ideal choice.

If your project is underway and you are eager to see your new product concept transformed into a physical prototype with precision and realism, Wsrcnc is your ideal partner for vacuum casting services. We specialize in creating high-precision prototypes at costs and lead times far below the norm, helping you accelerate innovation.

Whether you are looking to create a functional prototype for a groundbreaking design or need small batches for market testing, we offer comprehensive support to meet diverse needs.

Wsrcnc is certified to ISO 9001:2015 and ISO 13485, ensuring every delivery meets international quality standards. Our team of professional engineers provides full-process technical support, from conceptual design to final product development.

Choose Wsrcnc to take the next step—let us help you turn your ideas into reality with unparalleled precision and efficiency!