The Difference Between Metal Punching and Stamping

Metal punching and stamping are often regarded as synonymous processes in sheet metal forming. However, there is a clear distinction between them in practical applications: stamping encompasses a wide range of metal forming techniques, while punching specializes specifically in creating holes or apertures.

If an engineer incorrectly recommends one process over the other, it can lead to material waste, delivery delays, or cost overruns. The impact of such errors is particularly significant in large-scale production. Therefore, precise selection of the technical process is crucial.

This article will clearly analyze the core differences between punching and stamping and guide how to make reasonable selections based on application scenarios. You will gain an in-depth understanding of the operational principles, suitable materials, required equipment, and associated cost structures for both processes.

What is Sheet Metal Stamping?

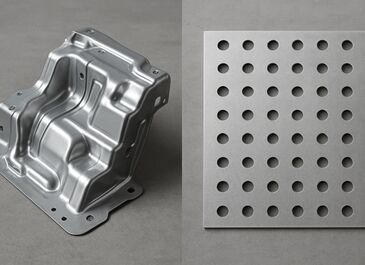

Sheet metal stamping is a cold working process that uses high pressure to form flat metal sheets into specific shapes. In this process, a flat metal sheet is placed into a stamping press, where a die applies pressure to shape the metal. Depending on specific requirements, the stamping process may involve cutting operations or may not involve material separation at all.

"Stamping" and "pressing" are often used synonymously, together covering a series of forming techniques completed on a press. Common stamping processes include punching, blanking, bending, embossing, flanging, and coining.

In terms of automation, stamping production can adopt either a single-stage mode, where each press stroke directly forms a complete part, or a multi-stage mode, where complex components are gradually formed through a series of die stations.

Leveraging its efficient forming capabilities, stamping technology is widely used in industries such as automotive, aerospace, electronics, and consumer goods. Typical stamped parts include automotive body panels, aircraft structural components, electronic component connectors, and various household appliance housings.

Advantages of Sheet Metal Stamping

High Efficiency: The fast pace of stamping production is particularly suited for mass manufacturing, significantly reducing unit costs.

High Consistency: Dies ensure extremely high dimensional consistency and interchangeability for each stamped part.

Good Strength: The cold forming process can strengthen the metal grain structure, typically enhancing the part's strength.

High Material Utilization: Through precise nesting, especially in progressive die production, material waste is minimized.

Capable of Forming Complex Parts: Can produce parts in various shapes, from simple brackets to complex automotive body panels.

Limitations of Sheet Metal Stamping

High Initial Investment Cost, Unsuitable for Small Batch Production: Stamping relies on dedicated, high-strength dies, whose design, manufacturing, and debugging are very costly and time-consuming. These dies can only produce specific parts. Therefore, the high mold cost is only amortized effectively in large-scale production. Using stamping for small batches or prototypes is highly uneconomical.

Extremely Poor Design Change Flexibility: Once a die is manufactured, the part's shape, dimensions, hole patterns, and other features are fixed. Any minor design change may require modifying or even scrapping the original die, necessitating reinvestment in costly and time-consuming new tooling. This severely restricts the flexibility for product iteration and optimization.

Limitations on Part Geometry Complexity: Stamping excels at producing thin-walled parts with primarily two-dimensional features (e.g., brackets, enclosures) but is less capable of manufacturing three-dimensional parts with complex curved surfaces, deep cavities, or enclosed hollow forms. These complex geometries often require additional processes or the welding and assembly of multiple parts, increasing manufacturing cost and complexity.

What is Metal Punching?

Metal punching is a metalworking process that uses dedicated punches and dies under powerful pressure to shear metal sheets, profiles, or other workpieces, thereby quickly and accurately processing holes, apertures, or shapes. Sheet metal punching can be an auxiliary operation performed after stamping processes. Examples of sheet metal punching include automotive panels, brackets, enclosures, and circuit boards.

Main Characteristics and Advantages of Punching:

High Efficiency and High Output: Punching is one of the fastest methods for creating holes in metal, especially suitable for high-volume, repetitive production.

High Consistency and Precision: Dies ensure that the position, size, and shape of every hole are highly consistent and interchangeable.

Low Cost: In high-volume production, the processing cost per individual part is reduced to a very low level.

Flexible Hole Shapes: Capable of not only round holes but also easily processing square, oval, custom-shaped holes, and various other complex apertures.

Good Edge Quality: Correct die clearance can produce clean, smooth hole edges, often eliminating the need for secondary finishing.

Limitations of Punching:

High Initial Tooling Cost: Manufacturing high-precision punches and dies is expensive.

Inflexible Design Changes: The hole shape and size are determined by the die. Modifications require changing the die, which is both costly and time-consuming.

Material Thickness Limitations: For excessively thick metal plates, punching requires extremely high tonnage, and edges may develop more burrs, potentially even leading to die damage.

Generates Scrap: The punched-out material becomes scrap, requiring optimized nesting design to improve material utilization.

What are the Differences Between Metal Punching and Stamping?

The difference between metal punching and stamping is a core concept in manufacturing. To understand it more intuitively, we can summarize it as follows: Punching is a type of stamping, but stamping encompasses far more than just punching.

The table below clearly illustrates their differences.

Core Differences at a Glance

| Aspect | Metal Punching | Metal Stamping |

|---|---|---|

| Relationship & Definition | A subset / specific operation of stamping. Focuses on creating holes or shapes in material. | An umbrella term for a category of metal forming processes. Encompasses various operations performed on sheet metal using a die and press. |

| Primary Purpose | To separate material—removing a portion from the workpiece. | To change the shape of the material—which may include separation (e.g., punching), deformation (e.g., bending), or a combination. |

| Process Nature | Analogous to using a hole punch; the goal is to create a hole, producing scrap. | Analogous to using a kitchen mold; it can cut (cookie cutter), bend, or stretch. |

| Outcome | Results in a sheet with holes and the scrap material that was punched out. | Results in a finished part, which could be a bracket, casing, body panel, etc. |

| Typical Applications | Ventilation holes, filters, screw holes, decorative perforations. | Automotive body panels, appliance enclosures, metal components for electronics. |

| Tooling Complexity | Relatively simple, typically a punch and die combination. | Can be extremely complex, including multi-station progressive dies. |

Detailed Explanation

Category Relationship: Part vs. Whole

This is the most fundamental difference.Bending: Folding the sheet to a certain angle.

Drawing: Forming a flat sheet into a hollow shape (e.g., a bowl).

Blanking: Also separates material, but the goal is to obtain a part with a complete external profile. Here, the punched-out part is the product, and the surrounding sheet is scrap (opposite to punching).

Coining/Embossing: Creating raised or recessed designs on the surface.

Stamping is a broad category, a collection of cold forming processes. Besides punching, it includes:

Punching is a specific process contained within the stamping category. One could say, "We use the punching operation within the stamping process to create these holes."

Process Purpose: Separation vs. Forming

The sole purpose of Punching is to create holes or apertures. It is a shearing and separation process resulting in material removal from the workpiece and generating scrap (slug).

The purpose of Stamping is to create a final part with a specific shape and function. This process may include a punching step, but it necessarily combines other forming operations. For example, manufacturing a computer case bracket might involve first "blanking" to get the outline, then "punching" screw holes, and finally "bending" the flanges.

Production Workflow

Punching is typically a single-step operation.

Stamping (especially for complex parts) is often a multi-step, sequential process. In advanced progressive dies, a metal strip feeds through multiple different stations sequentially, performing various stamping operations (like pilot hole punching, bending, drawing, final punching and blanking) at each station, ultimately outputting a complete part.

Summary

Simply put:

If you need to make one or more holes in a metal sheet, you are using punching.

If you need to manufacture a metal part (which may or may not include holes), you are using stamping. Punching is likely just one step in the manufacturing process of that part.

Therefore, when selecting a process, punching solves the "hole-making" problem, while stamping solves the "part forming" problem. Understanding this distinction is crucial for correctly planning production processes and costs.

How Can WSRCNC Empower Your Sheet Metal Fabrication?

Does your product design involve sheet metal components? Do you require professional services like laser cutting, bending, punching, riveting, welding, or stamping? WSRCNC provides comprehensive sheet metal fabrication solutions, covering the entire process from prototyping to mass production.

We possess a team of experienced stamping engineers and sheet metal experts dedicated to accurately translating your design concepts into high-quality physical products. Whether you need prototype verification or batch production, we can respond flexibly to meet diverse needs.

While ensuring quality and precision, we fully optimize the production process. The delivery cycle for standard projects can be shortened to as fast as 3 working days, helping you accelerate time to market.