Traditionally, jewelry making is considered an art form reliant on the handcrafting of artisans. However, with technological advancements, CNC machine tools have quietly become an indispensable core tool in the modern jewelry industry. With their unparalleled precision, efficiency, and consistency, they are redefining the boundaries of jewelry design and manufacturing.

If you're curious about how this technology is applied to the world of exquisite jewelry, this article provides a comprehensive guide, answering all your core questions from principles and applications to advantages and challenges.

1. Can jewelry be made using CNC machine tools?

The answer is: Absolutely. CNC machine tools are not only feasible, but also the cutting-edge choice in modern jewelry manufacturing. Driven directly by digital design files, they can carve and mill various metals and wax materials with extremely high precision, directly creating exquisite finished jewelry pieces or models for lost-wax casting

2. How is CNC machining technology applied in the jewelry industry?

CNC technology is applied throughout multiple stages of the jewelry industry, from design to finished product:

Direct Manufacturing: The final jewelry product is directly milled from a metal block (such as silver, gold, or platinum).

Model Making: Wax or resin models are sculpted for subsequent lost-wax casting.

Mold Making: Steel or brass molds are manufactured for mass production.

Surface Finishing: Precise texturing, openwork, and setting are performed.

3. How does CNC machining work in the jewelry industry?

The process can be simplified into three core steps:

3D Design: Designers use CAD (Computer-Aided Design) software to create a 3D digital model of the jewelry.

Path Programming: CAM (Computer-Aided Manufacturing) software converts the 3D model into toolpath code (G-code) that the CNC machine tool can recognize.

Precision Machining: The CNC machine tool automatically uses micro-tools to cut and carve on the material according to the code instructions, ultimately forming the solid piece.

4. What are the key CNC technologies in jewelry making?

Micro-milling: High-precision detail machining using extremely fine tools.

Multi-axis machining: Five-axis CNC machines can machine complex geometries from multiple angles without requiring multiple clamping operations.

High-speed cutting: Improves surface finish and reduces subsequent polishing work.

5. What types of jewelry can be made using CNC machining technology? What are its applications?

From simple rings and pendants to intricate reliefs, openwork bracelets, and earrings with complex patterns, CNC can create almost any type of jewelry. Its applications include:

High-end custom jewelry

Commercial mass productio

Personalized signatures and texture engraving

Jewelry with complex geometric architectural designs

6. What types of CNC machine tools are used in jewelry making?

Desktop CNC engraving machines: Suitable for small studios, primarily used for processing wax models and silver clay.

Three-axis vertical machining centers: The most commonly used type, suitable for most jewelry processing.

Five-axis simultaneous machining centers: Used for handling extremely complex and three-dimensional designs, a hallmark of top-tier precision manufacturing.

7. How CNC Machine Tools Aid Jewelry Design

CNC liberates designers' imaginations from the limitations of manual labor. It can perfectly realize:

Complex geometric shapes: such as fractals and honeycomb structures.

Perfect symmetry and repetition: ensuring that every product in a series is completely identical.

Rapid prototyping: quickly validating design effects before mass production.

8. How is Jewelry Molds Created Using CNC Machining Technology?

CNC can directly carve precise cavities into high-quality mold steel for creating vulcanization molds. These molds can produce thousands of uniform wax models, greatly improving the efficiency and consistency of mass production.

9. How Do CNC Machine Tools Handle Different Materials in Jewelry Making?

CNC technology has excellent material adaptability:

Wax and resin: used for creating casting models, easy to cut.

Silver, gold, and platinum: require adjustments to cutting speed, feed rate, and cooling method based on their hardness and toughness.

Titanium and stainless steel: higher hardness, requiring harder tools and specific machining parameters.

10. What are the advantages of using CNC machining in jewelry making?

Ultra-high precision and consistency: Errors can be measured in micrometers, ensuring flawless craftsmanship in every piece.

Extremely high efficiency: Automated production, 24/7 operation, suitable for large-volume orders.

Complex design realization: Breaking through the limitations of manual methods, enabling unprecedentedly complex designs.

Digital workflow: Design files are easy to modify, archive, and reuse.

11. What challenges does CNC machining face in jewelry making?

High initial investment: High costs for equipment and software.

High technical requirements: Requires mastery of both CAD/CAM technology and jewelry knowledge.

Material waste: Subtractive manufacturing inherently generates waste (although it is recyclable).

Detail limitations: Certain extremely subtle, organically textured handcrafted patterns remain difficult to perfectly replicate.

12. What are the precision and tolerances in CNC jewelry production?

The machining precision of high-end jewelry CNC can typically reach ±0.01 mm or even higher. This ensures tight settings, precise tenoning, and clear patterns.

13. How do jewelry manufacturers ensure quality control through CNC machining?

Process monitoring: Real-time monitoring of cutting forces and vibrations.

Precision measurement: Rigorous inspection of the first piece using microscopes, coordinate measuring machines, etc.

Tool management: Regular inspection and replacement of micro-tools to prevent precision degradation due to tool wear.

14. What are some design techniques for jewelry making using CNC machine tools?

Avoid sharp corners: Use small rounded corners to prevent stress concentration and facilitate tooling.

Consider tool size: Design details must not be smaller than the diameter of the tool used.

Optimize machining depth: Excessively deep cavities will prolong machining time and increase the risk of tool breakage.

Leave room for post-processing: Consider subsequent polishing and setting processes in the design.

15. How does CNC machining influence jewelry design trends?

CNC technology has directly spurred new design trends:

Architectural and Geometric Styles: Sharp lines and precise structures are perfectly presented.

Parametric Design: Complex and regular patterns are generated through algorithms.

Miroscopic Textures: Precise wood grain, carbon fiber, and other special effects are added to the surface of jewelry.

16. Safety Tips for Using CNC Machine Tools in Jewelry Making

Always wear safety goggles.

Ensure the workpiece is securely clamped.

Confirm the program simulation is correct before machining.

Avoid direct contact with rotating tools and chips.

Keep the work area clean and remove metal shavings promptly.

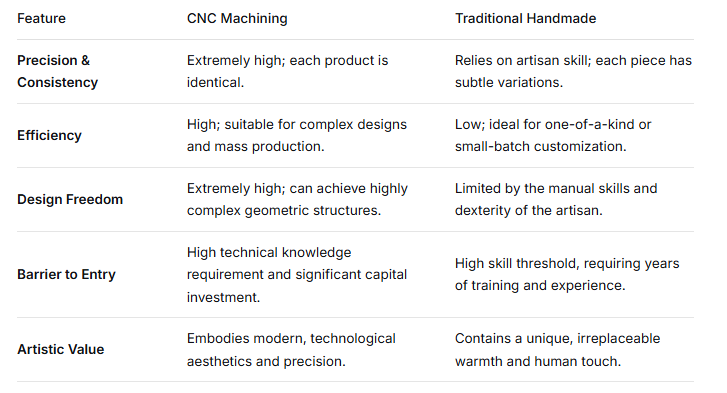

17. How does CNC machining differ from traditional jewelry making methods?

Characteristics: CNC machining Traditional handcrafting

18. Conclusion

CNC machining technology is not intended to replace traditional jewelry craftsmanship, but rather to provide it with a powerful new dimension. It brings jewelry manufacturing into a new era of digitalization and precision, enabling designers to turn more imaginative ideas into tangible reality. Whether pursuing ultimate efficiency in large-scale production or realizing unique and complex artistic creations, CNC has become a core competency that modern jewelry manufacturers must master. Embracing this technology means opening the door to the future world of jewelry.