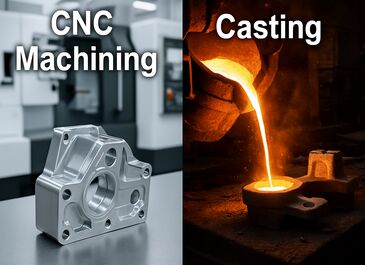

How to Choose Between CNC Machining and Casting?

As an engineer, when you complete the final feature in CAD software, the real challenge begins: how to manufacture this perfect model?

When your product design moves from drawings to reality, a crucial choice arises: choose the precise and rapid CNC machining, or rely on the powerful and flexible casting? This is not just a choice of process, but a comprehensive consideration of cost, efficiency, and performance.

Core Definition of CNC Metal Machining

CNC metal machining, short for Digital Controlled Metal Machining, is a manufacturing process that automates and precisely processes metal workpieces using pre-programmed computer software and instruction sets. Essentially, it involves "subtractive" manufacturing through cutting, using high-speed rotating precision tools to gradually remove excess material from a single block of metal, ultimately forming a part or product that meets design requirements.

Characteristics of CNC Metal Machining

Precision: Easily achieves IT7-IT8 or even higher tolerances; surface roughness Ra value can reach below 0.8μm, ensuring that every part in mass production perfectly replicates the design intent.

Flexibility: Capable of manufacturing a wide range of geometries, from simple planes and hole systems to extremely complex 3D curved surfaces, irregular structures, and thin-walled features. Parts with complex internal flow channels are particularly well-suited for prototyping, tooling, and machining.

Material Adaptability: From conventional metals such as aluminum, steel, stainless steel, and titanium alloys to difficult-to-machine materials like high-temperature alloys, copper, and magnesium, CNC machining can handle almost all engineering metal materials.

From Prototype to Mass Production: Although the unit cost is relatively high, its "soft" advantage of not requiring molds makes it unparalleled in terms of economy and speed during small-batch, multi-variety production and rapid iteration in R&D phases.

Advantages of CNC Machining:

Rapid Response: Digital files go directly to production, eliminating the long cycle of mold manufacturing.

Design Iteration Freedom: CAD models can be modified at the last minute with almost no additional cost.

Quality and Reliability: Dense materials with excellent mechanical properties (no casting defects such as porosity and shrinkage).

Challenges of CNC Machining:

Material Waste: Subtractive manufacturing inevitably produces chips, resulting in low material utilization.

Cost increases with volume: While the cost per unit is fixed, casting is less economical than mass production.

Design limitations: Tool accessibility issues exist (e.g., internal right angles), and structures such as deep holes and enclosed cavities cannot be machined.

Overview of Metal Casting

For engineers, metal casting represents an "additive manufacturing" approach, distinct from the "subtractive manufacturing" of CNC machining. Its core lies in creating a hollow cavity (mold), pouring molten metal into it, and allowing it to cool and solidify to obtain a solid part with the same shape as the cavity. This is a manufacturing method that achieves macroscopic shape control through changes in the state of matter.

Core Principles and Processes of Metal Casting

The essence of casting is a "shape replication" process, with a standard, interconnected process:

Pattern and Mold Design:

Pattern: The master mold manufactured based on the part drawing. Its shape and dimensions need to be precisely calculated to compensate for the shrinkage rate of the metal during cooling.

Mold: The cavity replicated from the pattern, used to form the shape of the part. Depending on the process, the mold can be a sand mold, a metal mold, etc.

Melting and Casting: The metal is melted at high temperature into a highly fluid liquid. The molten metal is then smoothly and continuously poured into the mold cavity through a gating system.

Solidation and Cooling: The molten metal releases heat within the mold, undergoing a phase transition from liquid to solid. Controlling the solidification sequence is crucial for ensuring casting quality and preventing defects such as shrinkage cavities and porosity.

Sand Removal and Cleaning: After the casting has cooled, it is either destructively removed (e.g., in sand casting) or the mold is opened to remove the casting. Gatings, risers, flash, and burrs are removed, followed by subsequent cleaning such as sandblasting and grinding.

Classification of Metal Casting Processes

Based on the type of mold, casting processes are mainly classified as follows:

Sand Casting:

Characteristics: Uses sand (such as quartz sand or chromite sand) mixed with a binder to create the mold. The mold is usually for single use.

Advantages: Extremely wide size range (from a few grams to hundreds of tons), strongest material adaptability, lowest cost, suitable for complex structures.

Disadvantages: Poor surface roughness, lower dimensional accuracy, and low production efficiency.

Metal mold casting:

Features: Uses metal (such as cast iron or steel) to make molds, which can be reused thousands to tens of thousands of times.

Advantages: Castings cool quickly, have a dense structure, good mechanical properties, high surface finish, and high dimensional accuracy.

Disadvantages: High mold cost; not suitable for casting particularly complex structures or high-melting-point alloys.

Pressure casting:

Features: Under high pressure, molten metal is rapidly filled into a metal mold cavity and solidified under pressure.

Advantages: Extremely high production efficiency and dimensional accuracy; can manufacture thin-walled, complex parts with excellent surface quality.

Disadvantages: Huge investment in equipment and molds; typically only suitable for mass production of non-ferrous metals (such as aluminum, zinc, and magnesium alloys).

Investment casting:

Features: Uses a fusible material (such as wax) to create a precise mold. Multiple layers of refractory material are wrapped around the mold surface to form a monolithic shell. The mold is then melted away, resulting in a hollow shell without a parting line for casting.

Advantages: Extremely high dimensional accuracy and surface finish; capable of casting extremely complex shapes (such as turbine blades).

Disadvantages: Long process flow, high cost, and size limitations.

Metal casting is the "macro-creator" of manufacturing, excelling at creating metal blanks with complex geometries from scratch.

Conclusion:

When your project meets the following characteristics, casting should be prioritized:

Large quantity requirements: Typically requiring thousands of pieces to spread the high mold costs.

Complex geometry: Especially with complex internal cavities, curved surfaces, or monolithic structures (such as engine blocks).

Cost sensitivity: Seeking the lowest possible unit cost in high-volume production.

Matching material properties: The selected alloy has good casting properties.

Summary

Ultimately, choosing between CNC machining and casting is not a race between processes, but a precise match to the core requirements of the project. Your decision path can be simplified to:

Choose CNC machining if: Your keywords are "prototype, complexity, precision, speed". When production volumes are low, design iterations are frequent, and there are extreme requirements for material properties and precision, CNC machining is the indispensable tool.

Choose metal casting if your keywords are "batch production, complexity, integration, and economy." Casting is an irreplaceable solution when high-volume production is required, parts have complex geometries (especially those with internal cavities), and the goal is to minimize unit cost at scale.

Final recommendation: For many complex parts, the combined process of "casting + CNC finishing" is often the optimal engineering solution—casting handles efficient forming, while CNC handles precise shape control. Utilizing the advantages of each process is key to transforming your excellent design into a successful product in the most efficient way.