Comprehensive Analysis of CNC Drilling: From Principles and Processes to Applications and Selection

CNC drilling, as a fundamental and crucial machining technology in modern manufacturing, is widely used in various industrial fields due to its high precision, high efficiency, and excellent repeatability. This article will systematically analyze all aspects of CNC drilling, providing you with a comprehensive reference guide.

What is CNC Drilling?

CNC drilling is a machining process that uses a Computer Numerical Control (CNC) system to precisely control the spindle of a drilling machine or machining center to automatically drill holes. It replaces traditional manual operation, using pre-programmed instructions (G-code) to direct the machine tool to machine precise holes at a specified position on the workpiece at a set speed and feed rate. Its core lies in automation, digitization, and precision.

How Does CNC Drilling Work?

The working principle of CNC drilling is essentially an automated process of "digital instructions driving physical execution." It follows a precise closed-loop control logic, transforming the design blueprint into an actual hole. This process can be broken down into four core stages:

Programming: Engineers use CAD/CAM software to design part models and generate CNC programs (G-code) containing information such as toolpaths, spindle speed, feed rate, and drilling depth.

Transmission and Parsing:The program is transmitted to the CNC drilling machine's control system, which parses the code instructions.

Execution: The machine tool controller drives servo motors to precisely control the movement of the workpiece table along the X and Y axes, positioning the hole to be machined directly below the spindle.

Machining: The spindle (Z-axis) drives the drill bit to rotate at high speed and feed downwards at the speed set in the program, completing the drilling action.

Repetition:After completing one hole, the system automatically positions itself for the next hole, repeating the above process until all holes are machined.

What are the different types of CNC drilling operations?

CNC drilling is far more complex than simply pressing a drill bit into a workpiece. Various specialized operation cycles have been developed to address different hole structures, materials, and production requirements. Understanding and correctly applying these types of drilling is key to achieving efficient and high-quality machining. Based on machining complexity and machine tool capabilities, CNC drilling operations are mainly divided into the following categories:

Spot Drilling:The most basic operation, where the spindle moves to a designated coordinate point for drilling.

Deep Hole Drilling:Used for machining holes with a large depth-to-diameter ratio (D/D ratio). This typically requires special drill bits (such as gun drills) and periodic chip removal.

Pecking Drilling:When machining deep holes, the drill bit feeds and retracts in segments in a "woodpecker" motion to effectively break and remove chips, preventing clogging and breakage.

Tapping:Machining internal threads in a drilled hole using a tap as a cutting tool.

Counter-sinking/Counter-heading:Using specific tools to machine a tapered or cylindrical countersunk face on the end of the hole for installing countersunk screws.

Summary and Selection Guide

| Operation Type | Primary Purpose | Key Characteristics | Applicable Scenarios |

|---|---|---|---|

| Spot Drilling | Drilling shallow holes | Simple action, high efficiency | Shallow holes, through holes |

| Peck Drilling | Drilling deep holes, chip evacuation difficulties | Segmented feed, full retraction, high safety | High length-to-diameter ratio, viscous materials |

| Chip Breaking Drilling | Efficient deep hole drilling | Segmented feed, slight retraction, high efficiency | Materials prone to chip breakage in deep holes |

| Deep Hole Drilling | Drilling very deep holes | Specialized tools, high-pressure coolant, single pass成型 | Ultra-high length-to-diameter ratio, high-requirement deep holes |

| Tapping | Creating internal threads | Strict synchronization between spindle rotation and feed | Threaded holes |

| Counterboring | Machining socket/seat at hole mouth | Improves assembly appearance and function | Countersunk screws, flat bearing surfaces |

| Reaming | Improving hole quality | Minimal cutting, high precision, high surface finish | Precision fit holes |

In actual programming, these operations typically correspond to different fixed-cycle G-codes (e.g., G81 for spot drilling, G83 for pecking drilling, G84 for tapping, etc.). Skilled CNC programmers will flexibly select the most suitable operation type based on the workpiece material, hole characteristics, and machining requirements to achieve the best machining results.

4. What are the main components of a CNC drilling machine?

A CNC drilling machine is a complex mechatronic system. Its core lies in accurately translating digital instructions into physical drilling actions. To understand its working principle, it is first necessary to understand its various core components. We can divide these components into the following major systems:

Bed/Frame: Provides structural stability and rigidity.

Spindle: The core component that drives the drill bit's rotation; its power and speed range determine the machining capacity.

CNC System: The "brain" of the machine tool, used to receive and analyze programs and control all movements.

Servo Drive System: Includes servo motors and ball screws, responsible for accurately driving the X, Y, and Z axes.

Tool magazine: Used for automatic storage and changing of different tools, improving machining efficiency.

Worktable and fixture: Used for clamping and fixing workpieces.

Coolant system: Used to cool tools and workpieces and flush away chips.

5. What are the different types of CNC drilling machines?

CNC drilling machines are not a single type of machine. Based on their structure, function, and application, they can be divided into several types. Understanding these different types helps in selecting the most suitable equipment for specific production needs. Based on structural form and application, they are mainly divided into:

Vertical CNC drilling machine: The spindle is arranged vertically; this is the most common type, suitable for sheet metal and disc-shaped parts.

Horizontal CNC drilling machine: The spindle is arranged horizontally; suitable for drilling holes on the sides of box-shaped parts, facilitating chip removal.

Gantry CNC drilling machine: Suitable for machining large and heavy workpieces, such as wind turbine foundations and large molds.

Deep hole drilling machine: A special-purpose machine tool designed specifically for deep hole drilling.

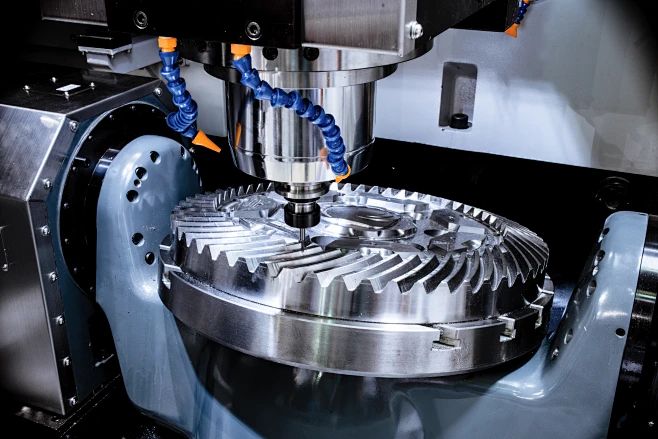

Machining Center: A multi-functional CNC machine tool integrating drilling, milling, tapping, boring, and other functions, it is currently the most mainstream configuration.

6. What are the different types of CNC drill bits?

The choice of drill bit directly affects machining quality and efficiency. Common types include:

Twist Drill: The most versatile drill bit, suitable for most materials.

Center Drill: Used to pre-machine a positioning center hole before drilling to ensure accurate subsequent drilling position.

Gun Drill: Designed specifically for deep holes, with internal coolant channels, enabling high-precision deep hole machining in a single pass.

Step Drill: Can machine holes of different diameters and countersunk holes in one pass.

Indexable Insert Drill Bits: Uses replaceable carbide inserts, suitable for high-efficiency mass production.

Sheet Metal Drill Bits: Specifically designed for thin sheet metal machining, producing clean, burr-free holes.

7. What are the main parameters of CNC drilling?

Key process parameters determine the machining effect:

Spindle speed: The speed at which the drill bit rotates, measured in RPM.

Feed rate: The speed at which the drill bit moves axially, measured in mm/min or inch/min.

Cutting speed: The linear velocity of the drill bit's cutting edge relative to the workpiece, measured in m/min.

Feed per revolution: The distance the drill bit travels per spindle revolution; it determines the chip thickness.

Drill depth: The axial depth of the hole to be machined.

8. What materials does CNC drilling support?

CNC drilling supports almost all machinable engineering materials, including:

Metals: Steel, stainless steel, aluminum alloys, cast iron, brass, copper, titanium alloys, etc.

Plastics: ABS, nylon, polycarbonate, PEEK, etc.

Composite materials: Carbon fiber composites, glass fiber, etc.

Wood.:Different materials require different drill bit types, coatings, and cutting parameters.

9. What are the applications of CNC drilling?

CNC drilling applications are ubiquitous, covering almost all manufacturing industries:

Aerospace: Aircraft structural components, engine parts.

Automotive Industry: Engine blocks, gearbox housings, chassis parts.

Mold Industry: Cooling water holes and ejector pin holes in injection molds and die-casting molds.

Electronics Industry: Through holes and mounting holes on printed circuit boards (PCBs).

General Machinery: Connection holes on various frames, housings, and flanges.

10. What are the advantages of CNC drilling technology?

High precision and high repeatability: Computer control eliminates human error, ensuring consistency in batch products.

High efficiency: Automated processing, high speed, and the ability to perform multi-axis linkage and simultaneous processing of multiple workpieces.

High flexibility: Parts with different hole positions can be processed by modifying the program, with rapid conversion.

Strong ability to handle complexity: Easily processes complex patterns such as inclined holes and holes on three-dimensional curved surfaces.

Low labor intensity: Operators are mainly responsible for clamping and monitoring, with relatively lower skill requirements.

11. What are the limitations of CNC drilling?

High initial investment: CNC equipment and supporting software are expensive.

Technical requirements for programmers and operators: Requires CAD/CAM knowledge and machine tool operation experience.

Unsuitable for extremely simple single-piece machining: For simple parts requiring only a few holes, programming and preparation time may exceed the machining value.

Tooling costs: High-performance drill bits (such as carbide and coated drill bits) are a continuous consumable cost.

12. Is CNC drilling cost-effective?

For medium to high-volume production, CNC drilling is extremely cost-effective. Its high efficiency, low scrap rate, and labor cost savings can quickly amortize the initial investment. Even for small-batch, multi-variety production, its rapid changeover capability demonstrates good economic efficiency. However, for single-piece, extremely simple drilling tasks, traditional manual drilling machines may be more economical.

13. How long does CNC drilling typically take?

Machining time cannot be generalized; it depends on:

The number and depth of holes.

The hardness of the material.

The cutting parameters used (speed and feed).

The rapid traverse and tool change speeds of the machine tool.

Typically, machining a standard through hole (such as an M6 threaded pilot hole) in aluminum may only take a few seconds.

14. What are the important factors to consider for efficient CNC drilling?

Correct drill selection: Choose the appropriate drill type and coating based on the material, hole diameter, and hole depth.

Optimized cutting parameters: Set the optimal speed and feed based on the material, tool, and machine tool rigidity.

Effective chip removal: Ensure chips are smoothly removed, avoiding chip entanglement and tool breakage.

Stable fixture: Robust clamping is a prerequisite for ensuring accuracy and safety.

Sufficient cooling and lubrication: Reduce cutting temperature, extend tool life, and improve hole wall quality.

15. What is the difference between CNC drilling and thread tapping?

These are two consecutive processes:

Drilling: Using a drill bit, a smooth hole (without threads) is machined into a solid material.

Tapping: Using a tap, an internal thread is cut into the inner wall of the drilled hole.

Simply put, drill first, then tap.

16. What is the difference between CNC drilling and CNC milling?

Drilling: The tool (drill bit) mainly feeds along the axial direction (Z-axis) to create or enlarge a circular hole.

Milling: The tool (milling cutter) rotates while moving in multiple directions (X, Y, Z), used to machine complex geometries such as planes, contours, and cavities.

Drilling is a "point" machining operation, while milling is a "surface" and "contour" machining operation.

17. What is the difference between a CNC drilling machine and a CNC lathe?

CNC drilling machine/machining center: The workpiece is usually fixed on the worktable, and the spindle drives the tool to rotate and move for machining. Suitable for machining plate-type and box-type parts.

CNC lathes: The workpiece is rotated by the spindle, while the cutting tool (usually not rotating or rotating slowly) moves to perform cutting. Suitable for machining rotating parts such as shafts and discs. Modern milling and turning centers also integrate drilling heads, allowing drilling on rotating parts.

18. What is the maximum hole depth achievable with CNC drilling?

The maximum hole depth is limited by the type of drill bit and the machine tool's travel:

Standard twist drills: A depth-to-diameter ratio of 10:1 to 12:1 is generally recommended. For example, with a 10mm drill bit, the maximum hole depth is approximately 100-120mm.

Deep hole drills (such as gun drills): Can machine deep holes with depth-to-diameter ratios as high as 100:1 or even 300:1. This requires specialized equipment and cutting tools.

19. Conclusion:

CNC drilling is one of the cornerstone technologies of modern precision manufacturing. It achieves a significant leap in precision, efficiency, and automation in drilling by perfectly combining digital control with machining. From simple connecting holes to complex deep holes, CNC drilling offers reliable solutions. Despite initial investment and skill requirements, its long-term benefits and competitive advantages make it an indispensable process in modern factories. Understanding its principles, types, parameters, and applications is key to effectively utilizing this technology to improve product quality and production efficiency.